A washing machine control method and washing machine

A control method and washing machine technology, which are applied to the control device of washing machines, washing devices, textiles and papermaking, etc., can solve the problems of increasing the cost of washing machines and complicated structures, and achieve the effects of shortening washing time, improving washing effect, and saving washing water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

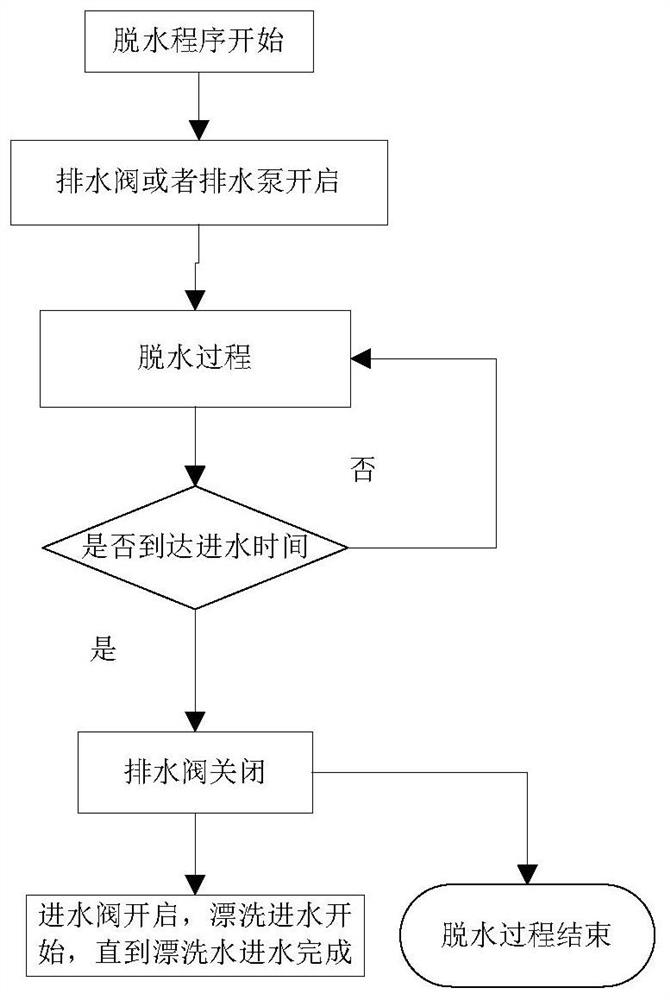

Embodiment 1

[0057] A washing machine control method of the present embodiment includes:

[0058] In the dehydration process, at the end of the dehydration process, the drainage device is controlled to close, and the first water intake process is performed, and the influent water is retained in the washing machine for the rinsing process;

[0059] And, in the rinsing process, the water inlet valve is opened, the water inlet is controlled to the set water level, and the rinsing is started.

[0060] In the washing machine control method of the present embodiment, water is fed during the dehydration process. Due to the rotation of the inner drum during dehydration, the incoming water can flush the drum wall and take away the dirt of the clothes, thereby improving the washing effect; The drainage device is closed in advance to ensure that the incoming water is not wasted and used for the subsequent rinsing process, saving laundry water.

[0061] Therefore, the washing machine control method o...

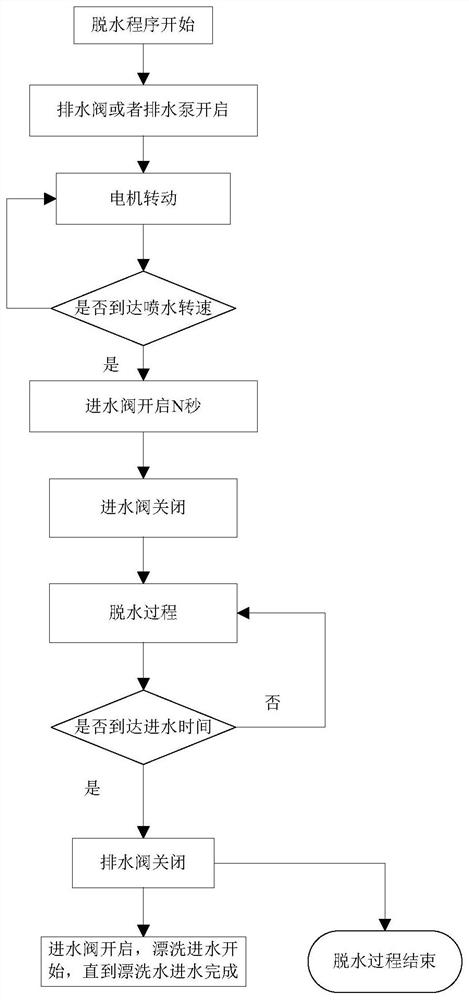

Embodiment 2

[0085] The difference between the present embodiment and the first embodiment is only that a technical solution for judging whether the dehydration process reaches the end stage is proposed, specifically as follows:

[0086] The dehydration process of this embodiment includes:

[0087] Determine whether the motor that provides dehydration power is powered off;

[0088] If the judgment result is yes, the dehydration process is the last stage, the drainage device is controlled to be closed, the water inlet valve is opened, and the first water inlet process is performed. If the judgment result is no, the dehydration is continued.

[0089] During the dehydration process, the inner cylinder is still in a state of high-speed rotation due to inertia for a period of time when the motor stops power supply, that is to say, the dehydration process does not end if the motor stops power supply.

[0090] This embodiment utilizes the characteristics of this working process, and starts to en...

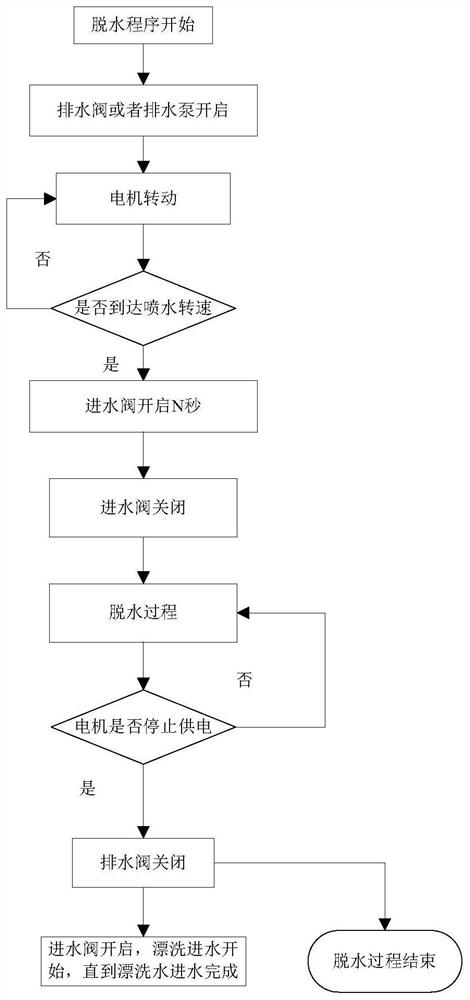

Embodiment 3

[0092] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that, in a method for controlling a washing machine in this embodiment, the dehydration process further includes a second water intake process, including:

[0093] The washing machine starts dehydration. During the dehydration process, the water inlet valve is controlled to open for a certain period of time, and the drainage device remains open.

[0094] The main function of the second water inlet process in this embodiment is to flush the drum wall and take away the dirt in the clothes. At this time, the drain valve or the pump is opened, which is conducive to the discharge of dirt. Therefore, the second water inlet process can have a good effect of spray washing and improve the washing effect.

[0095] In order to achieve the spray washing effect of the second water inlet process, the time point of the second water inlet process in this embodiment also needs to be designed with special feature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com