Assembly welding fixture for airport transportation roller bed connecting beam

A technology for welding tooling and connecting beams, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of time-consuming and low efficiency, and achieve the effect of high-efficiency production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

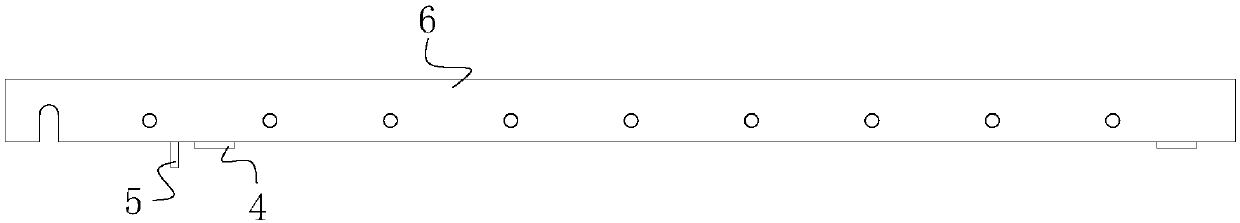

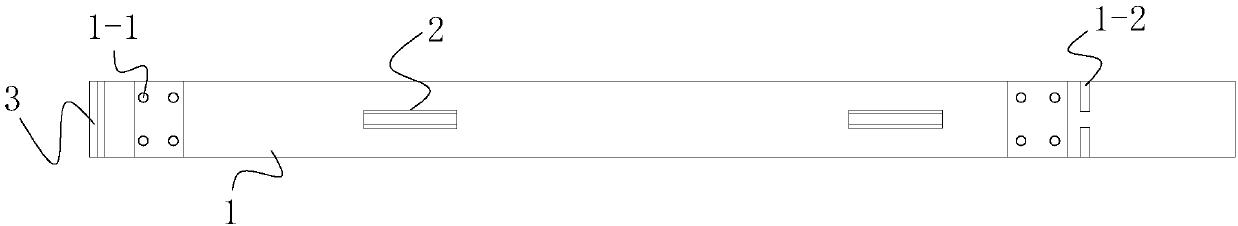

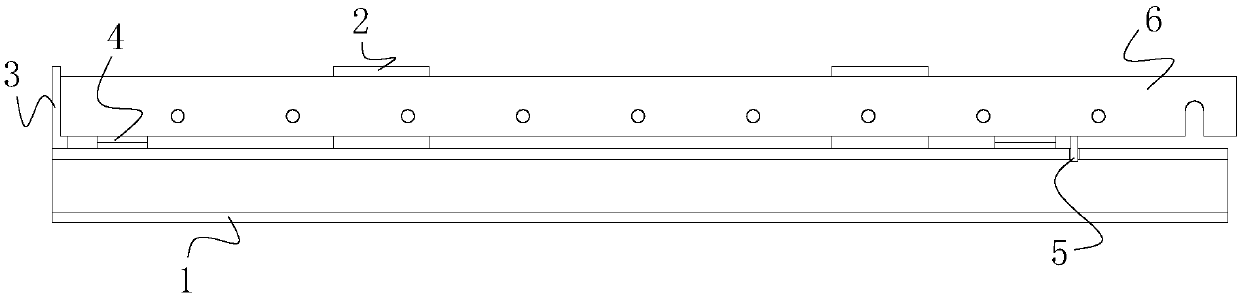

[0016] see figure 2 with image 3 , a butt welding tool for connecting beams of airport transport rollers, characterized in that it includes a base 1, a transverse positioning plate 2 and a longitudinal positioning plate 3.

[0017] The longitudinal positioning plate 3 is fixed on the base 1, the transverse positioning plate 2 is fixed on the base 1, the longitudinal positioning plate 3 has a longitudinal positioning plane, and the transverse positioning plate 2 has a The horizontal positioning plane, the longitudinal positioning plane is perpendicular to the horizontal positioning plane, the base 1 is provided with a positioning hole 1-1, and the base 1 is provided with a positioning slot 1-2. In this embodiment, the longitudinal position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com