Pipe stitch welding all-in-one machine

An all-in-one machine and pipe technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problem of large floor space, reduce site occupation, increase welding function, and improve processing ability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

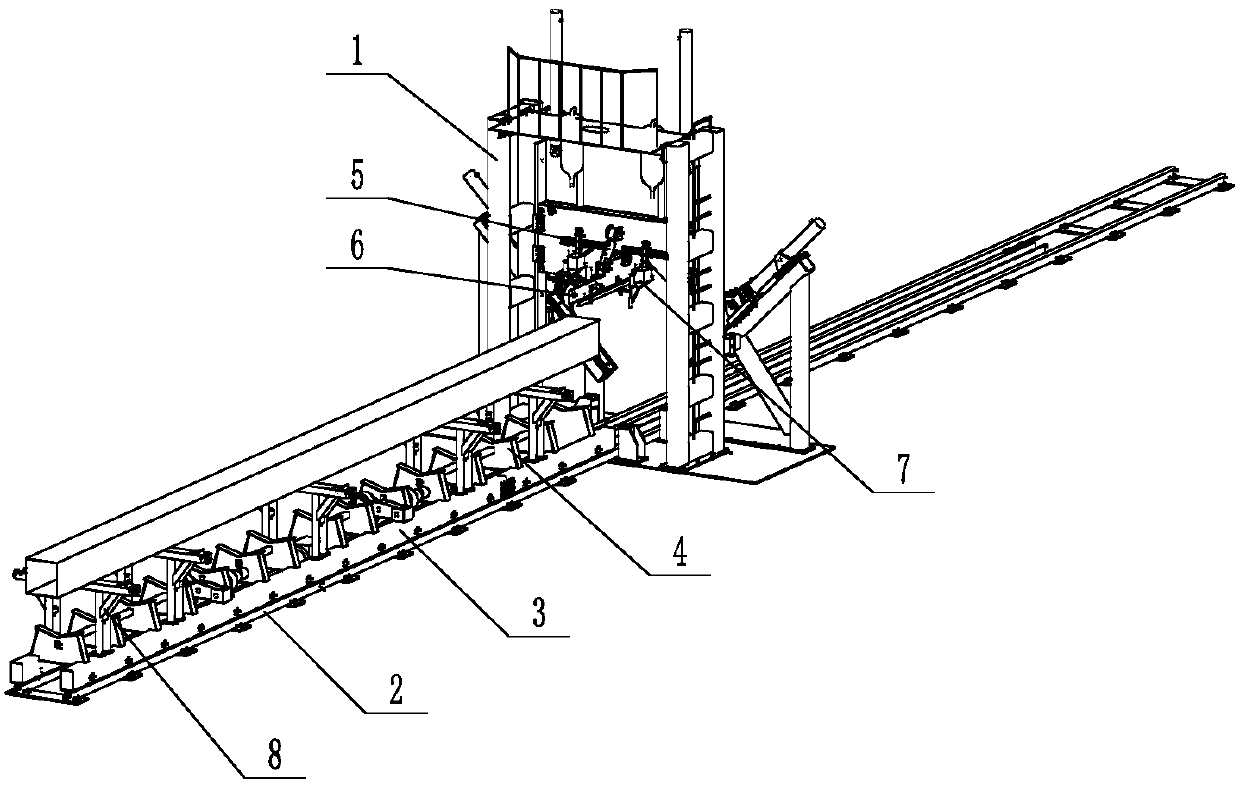

[0017] Such as Figure 1-4 As shown, the present invention comprises a body 1, a track 2 arranged on the lower side of the body 1, a trolley 3 arranged at the upper end of the track 2, a workpiece positioning device 4 arranged at the upper end of the trolley 3, and the body 1 includes a cylinder 5 and a The rotating shaft is connected to the intermediate welding torch 6 at the lower end of the body 1 , and auxiliary welding torches 7 are arranged on both sides of the intermediate welding torch 6 . The upper end of the trolley 3 is also provided with a workpiece clamping device 8 .

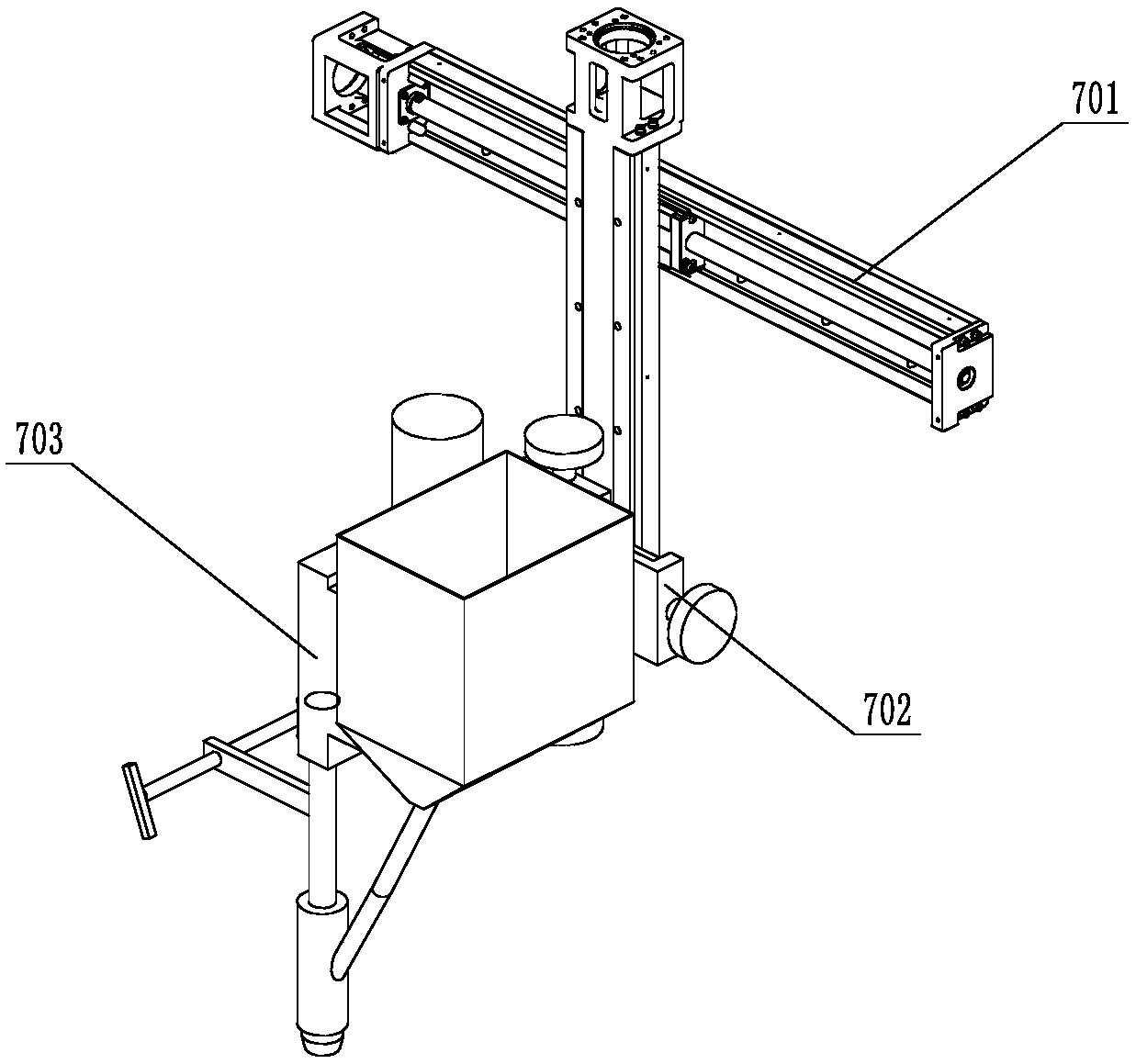

[0018] The auxiliary welding torch 7 includes a cross slide 701 , a linear module 702 , and a welding machine 703 , and the linear module 702 is driven 704 by a servo motor.

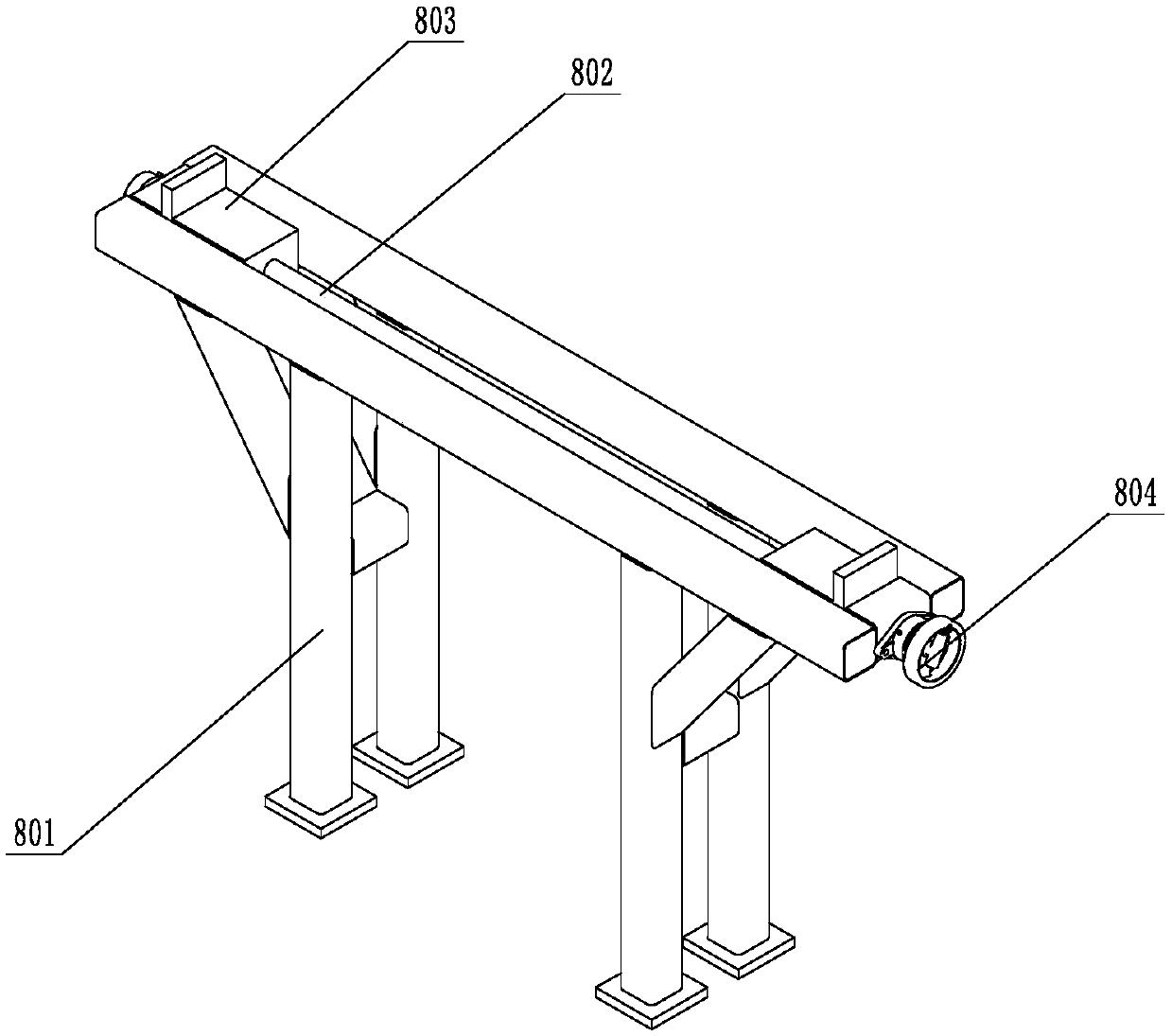

[0019] The workpiece clamping device 8 includes a bracket 801, the upper end of the bracket 801 is connected with a lead screw 802 through a bearing, and the screw 802 is connected with a symmetrical limit slider 803 by thre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com