A kind of carbon dioxide electrochemical reduction catalyst and preparation method thereof

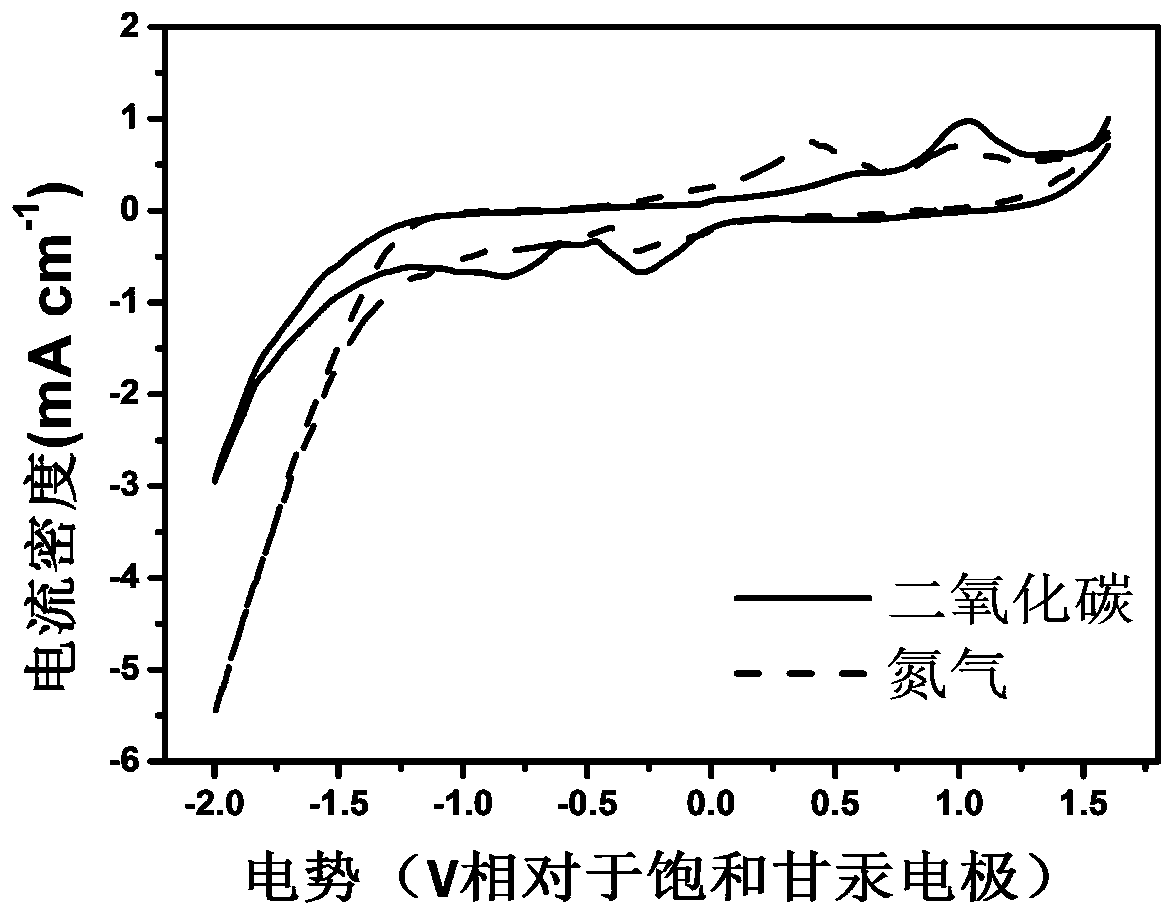

A carbon dioxide and catalyst technology, which is applied in the field of carbon dioxide electrochemical reduction catalyst and its preparation, can solve the problems of poor electrical conductivity and limitation of tin dioxide, and achieve increased electrochemical reduction catalytic activity, enhanced selectivity, and easy operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1. Synthesis of tetramethylguanidine lactate ionic liquid

[0029] (d) Take 5% ethanol solution of 1,1,3,3-tetramethylguanidine in an ice-water bath, and magnetically stir for 3 hours;

[0030] (e) adding the ethanol solution of lactic acid dropwise into a 5% ethanol solution of 1,1,3,3-tetramethylguanidine, and stirring in an ice-water bath for 5 hours;

[0031] (f) Stir for 24 hours; at a temperature of 60 degrees Celsius, use a rotary evaporator to rotate.

[0032] 2. Preparation of catalyst precursor

[0033] 34 mg of palladium chloride was dissolved in 7 ml of tetramethylguanidine lactate ionic liquid to obtain a mixed solution, which was heated in an oil bath at a temperature of 80 degrees Celsius to obtain a catalyst precursor.

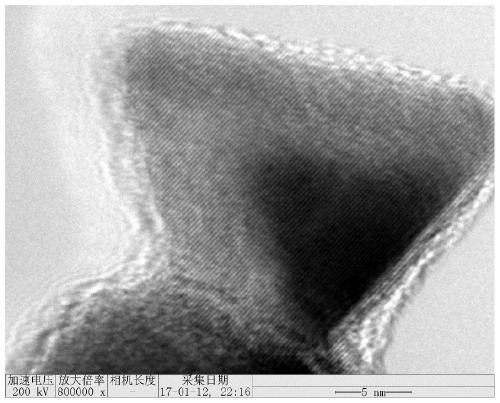

[0034] 3. Preparation of carbon dioxide electrochemical reduction catalyst "pyramid" palladium nanoparticle catalyst

[0035] (d) Dissolve 60 mg of ascorbic acid and 105 mg of polyvinylpyrrolidone in 3 ml of tetramethylguanidine lacta...

Embodiment 2

[0040] 1. Synthesis of tetramethylguanidine lactate ionic liquid

[0041] (a) Take 5% ethanol solution of 1,1,3,3-tetramethylguanidine in an ice-water bath, and magnetically stir for 3 hours;

[0042] (b) adding the ethanol solution of lactic acid dropwise into a 5% ethanol solution of 1,1,3,3-tetramethylguanidine, and stirring in an ice-water bath for 6 hours;

[0043] (c) Stir for 30 hours; at a temperature of 60 degrees Celsius, use a rotary evaporator to rotate.

[0044] 2. Preparation of catalyst precursor

[0045] 34 mg of palladium chloride was dissolved in 9 ml of tetramethylguanidine lactate ionic liquid to obtain a mixed solution, which was heated in an oil bath at a temperature of 90 degrees Celsius to obtain a catalyst precursor.

[0046] 3. Preparation of carbon dioxide electrochemical reduction catalyst "pyramid" palladium nanoparticle catalyst

[0047] (d) Dissolve 60 mg of ascorbic acid and 105 mg of polyvinylpyrrolidone in 3 ml of tetramethylguanidine lacta...

Embodiment 3

[0052] 1. Synthesis of tetramethylguanidine lactate ionic liquid

[0053] (a) Take 5% ethanol solution of 1,1,3,3-tetramethylguanidine in an ice-water bath, and magnetically stir for 3 hours;

[0054] (b) adding the ethanol solution of lactic acid dropwise into a 5% ethanol solution of 1,1,3,3-tetramethylguanidine, and stirring in an ice-water bath for 5 hours;

[0055] (c) Stir for 36 hours; at a temperature of 60 degrees Celsius, use a rotary evaporator to rotate.

[0056] 2. Preparation of catalyst precursor

[0057] 34 mg of palladium chloride was dissolved in 8 ml of tetramethylguanidine lactate ionic liquid to obtain a mixed solution, which was heated in an oil bath at a temperature of 100 degrees Celsius to obtain a catalyst precursor.

[0058] 3. Preparation of carbon dioxide electrochemical reduction catalyst "pyramid" palladium nanoparticle catalyst

[0059] (d) Dissolve 60 mg of ascorbic acid and 105 mg of polyvinylpyrrolidone in 3 ml of tetramethylguanidine lactat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com