combine harvester

A combine harvester and machine body technology, which is applied to harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of deformation of the right wall and narrow maintenance space of the threshing device, and achieve the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

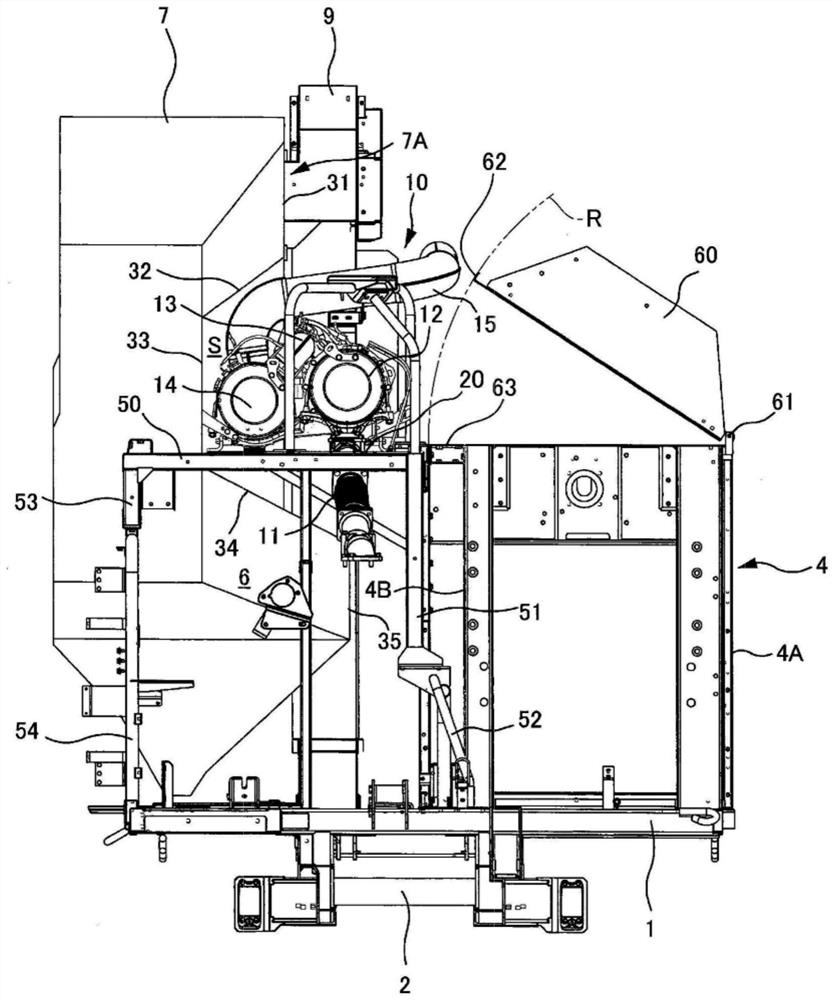

[0037] The present invention will be described with reference to the accompanying drawings. In addition, from the operator's point of view, directions are simply indicated by describing the front as the front, the rear as the rear, the right-hand as the right, and the left-hand as the left.

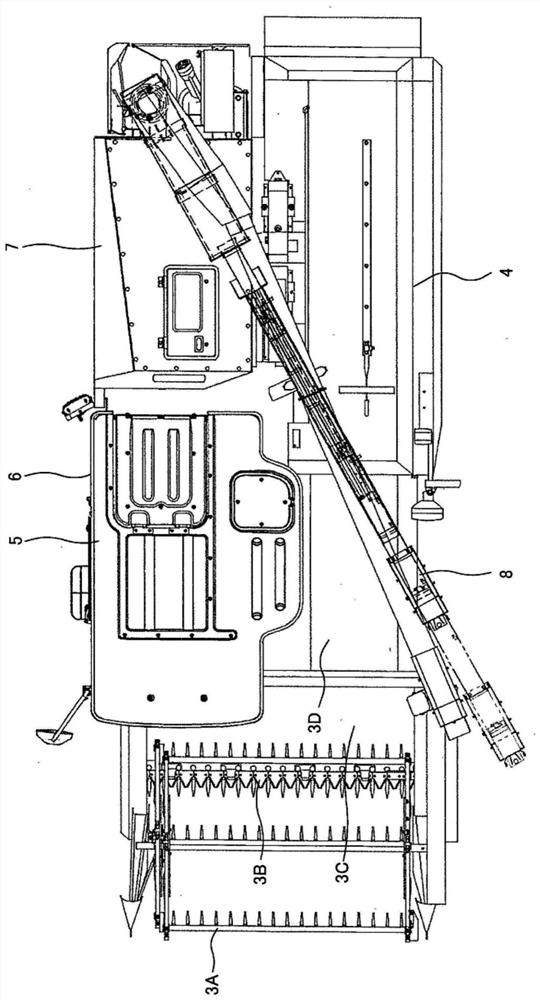

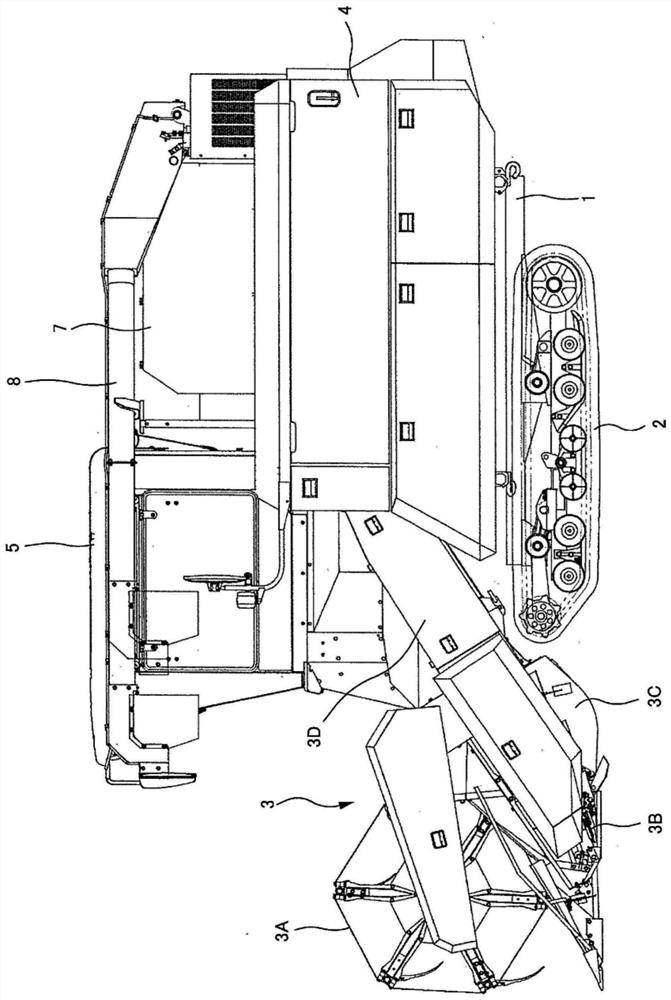

[0038] Such as figure 1 , 2 Shown, with regard to general-purpose combine harvester, the underside of body frame 1 is provided with the traveling device 2 that is made of left and right pair of caterpillars that travels on the soil surface, is provided with harvesting farmland on the front side of body frame 1. The harvesting pre-processing device 3 of the grain stalk is provided with a threshing device 4 for threshing / screening the harvested grain stalks at the rear left part of the harvesting pre-processing device 3, and is provided with a rear right part of the harvesting pre-processing device 3. The control unit 5 for the operator to take.

[0039] The lower side of the control par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com