Method for measuring higher frequency vibration by utilizing low-speed camera based on fringe projection method

A fringe projection, high-frequency vibration technology, applied in measuring devices, measuring ultrasonic/sonic/infrasonic waves, instruments, etc., can solve the problems of increasing measurement cost, data storage cost, camera cost, etc. Good reliability and portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

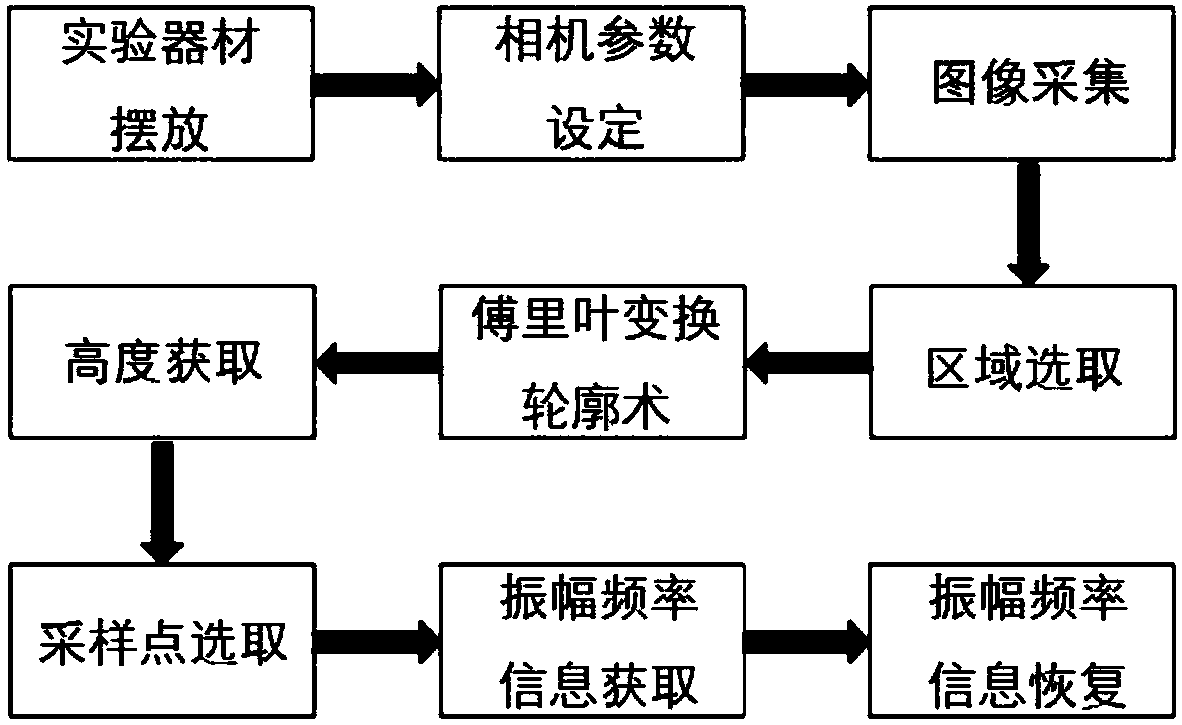

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific examples.

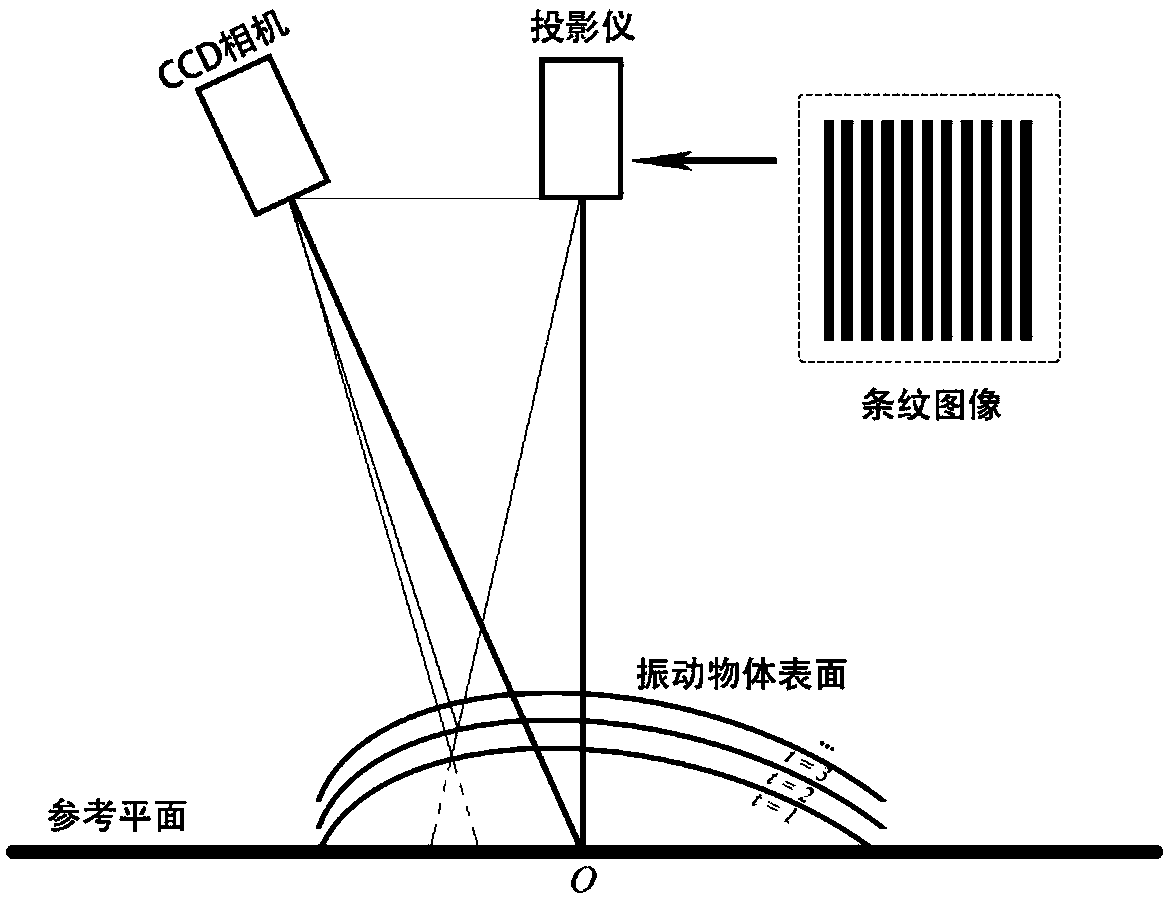

[0022] see figure 1 , the schematic diagram of the principle of the present invention based on the fringe projection method: the stable vibrating object to be measured is placed on the reference plane, and its surface is in a different position at each different moment. The black and white stripe images are generated through the program, connected to the projector and projected on the surface of the object, and the CCD camera is responsible for collecting and storing the images of the object at different times.

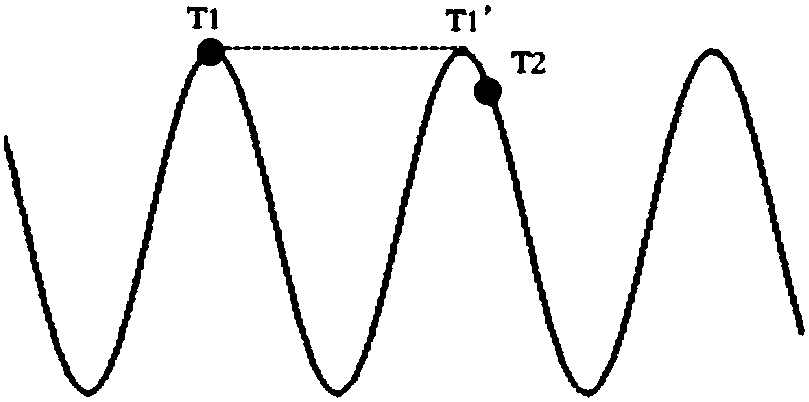

[0023] The fringe generation device generates the black and white fringes shown in the dotted line box through the program, connects to the projector, and adjusts the focus knob of the projector so that the generated image is clearly projected on the vibrating object to be tested. Controlling a vibrating object produces a low-frequency v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com