Check valve, diaphragm pump, and printing apparatus

A technology of printing device and one-way valve, which is applied in the direction of valve device, printing, pumping device for elastic fluid, etc., which can solve the problems of decreased infusion capacity or sealing performance, decrease in infusion capacity sealing performance, damage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In addition, in each of the following drawings, each layer or each member may be shown on a scale different from actual ones in order to make each layer or each member a recognizable size.

[0073] check valve

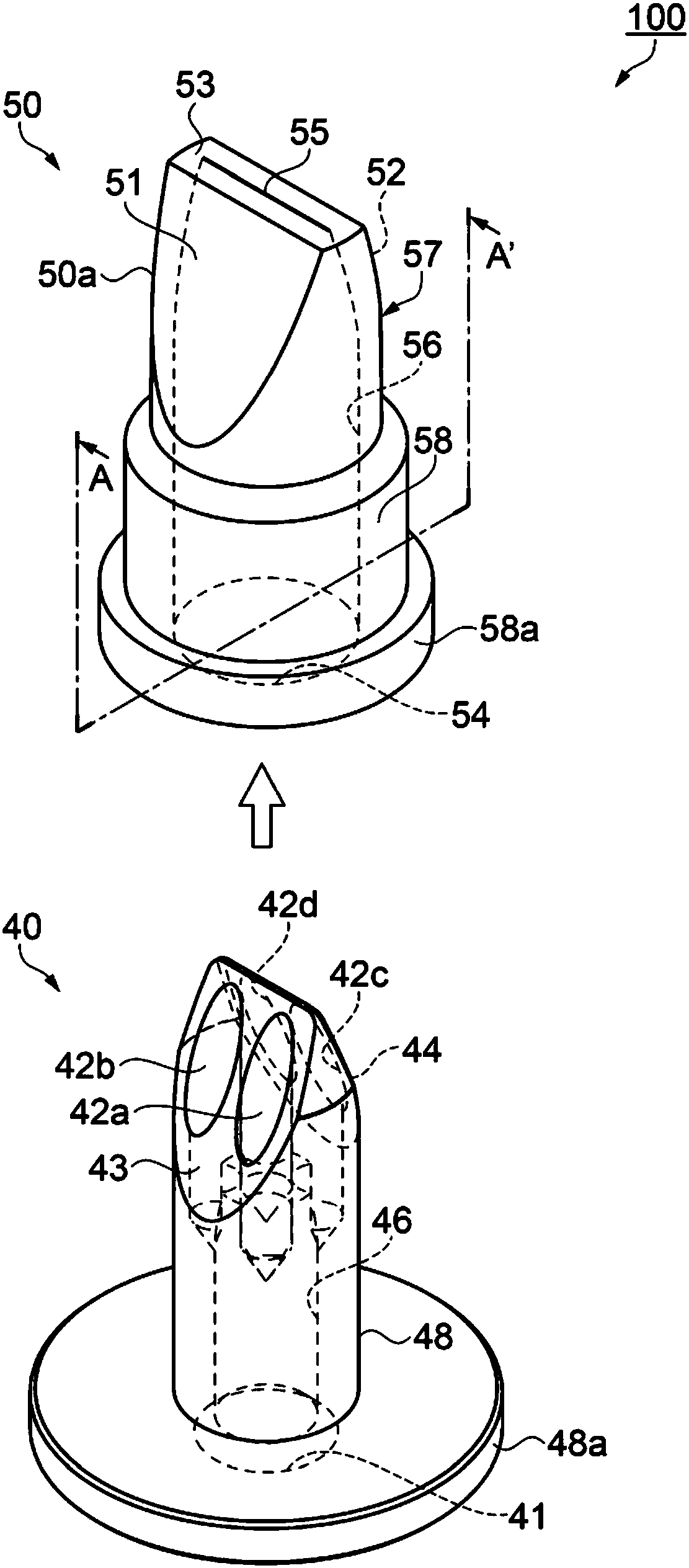

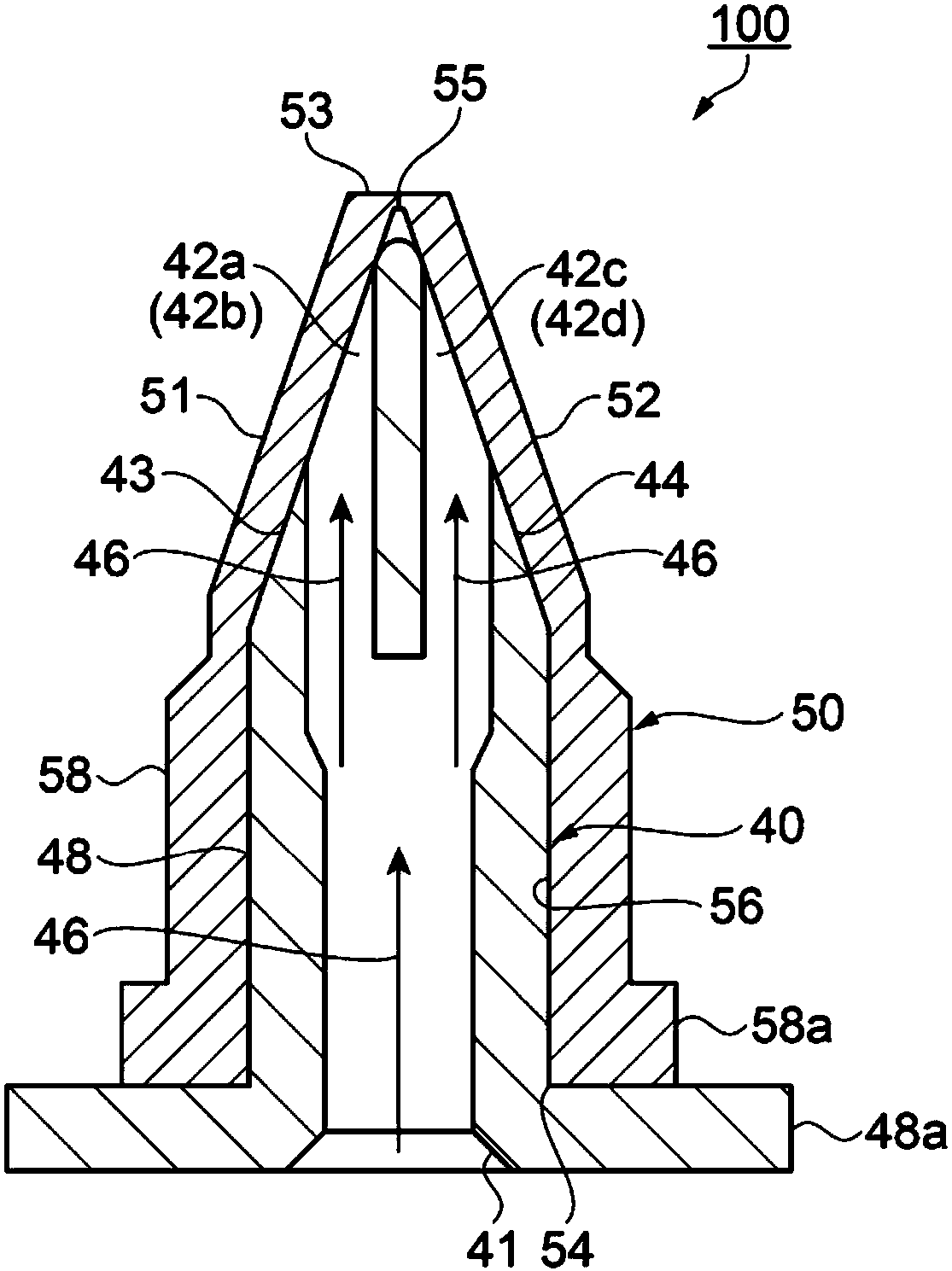

[0074] figure 1 It is an exploded assembly view of the one-way valve related to the embodiment. figure 2 for figure 1 A-A' sectional view in the state where the check valve is assembled.

[0075] First, a schematic configuration of the check valve 100 according to the present embodiment will be described.

[0076] Such as figure 1 as well as figure 2 As shown, the check valve 100 includes a duckbill valve 50 and a support member 40 inserted into the duckbill valve 50 .

[0077] The duckbill valve 50 is formed of a soft material such as synthetic rubber, and is constituted by a cylindrical base 58 and a duckbill part 57 formed in the shape of a duck's mout...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com