A continuously variable compression ratio engine device and compression ratio conversion method

A variable compression ratio technology, applied in engine control, machines/engines, mechanical equipment, etc., can solve problems such as inability to achieve optimal performance and invariable engine compression ratio, so as to improve thermal efficiency, realize volume, and realize continuous reliability. change effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

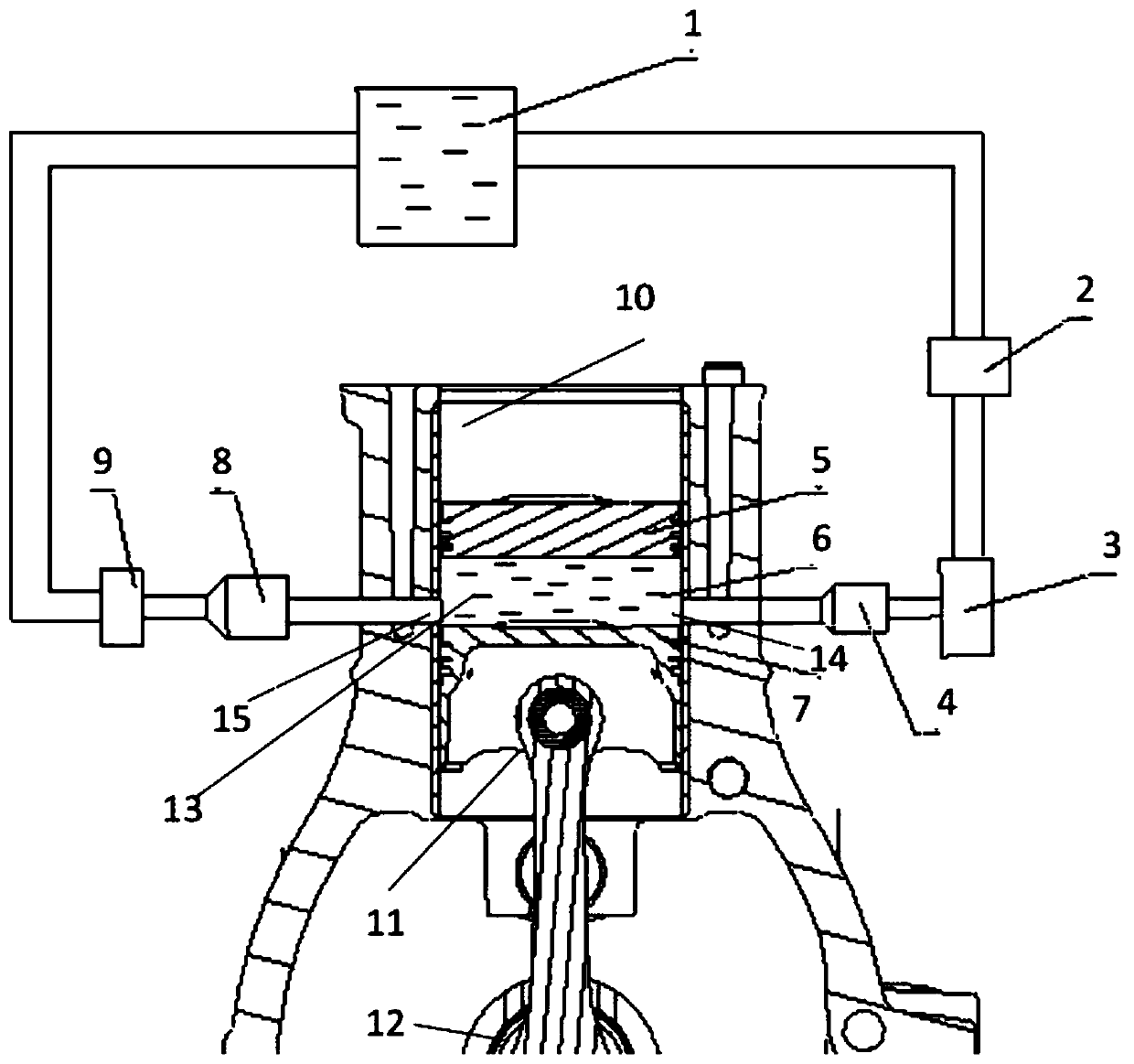

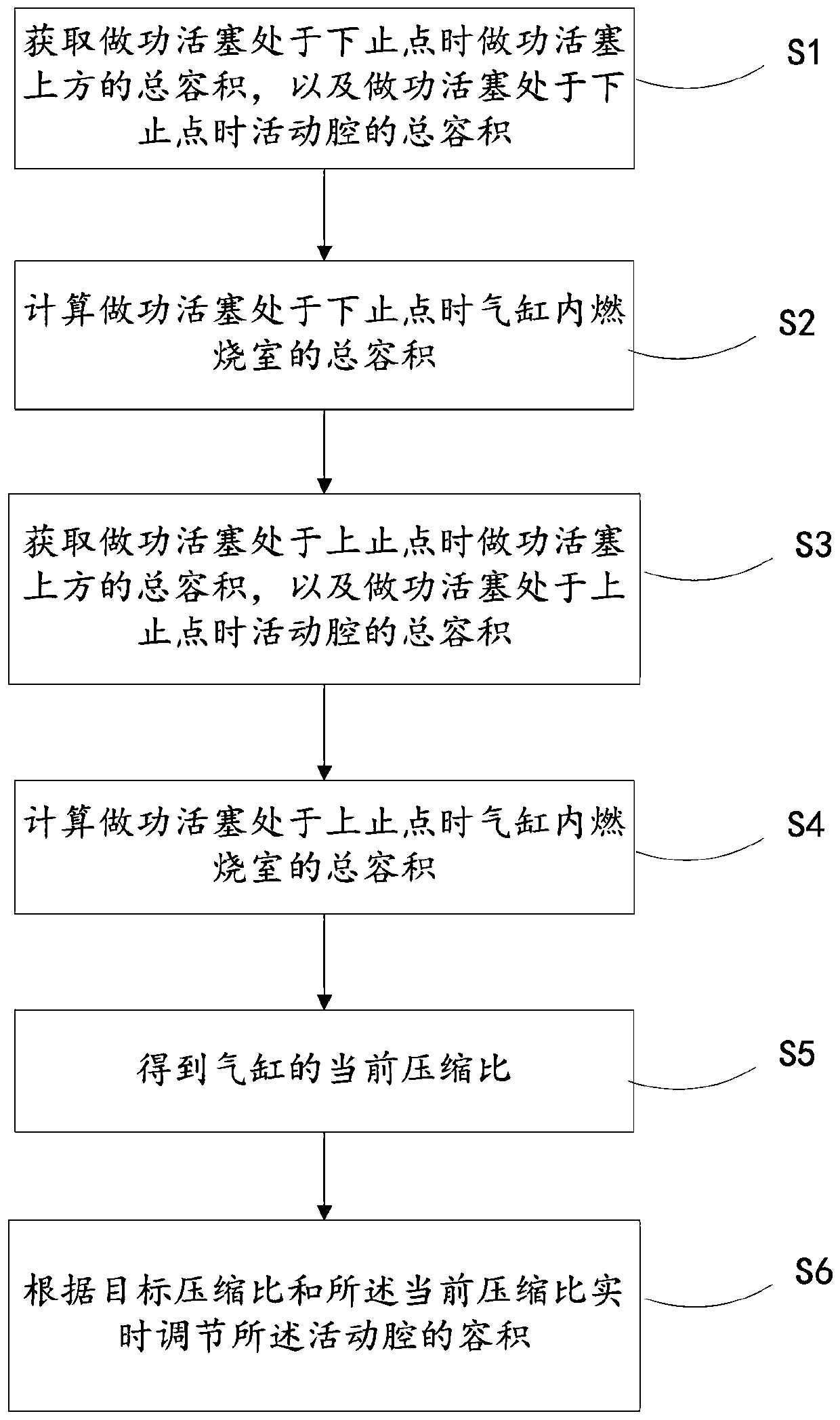

[0031] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0032] The mechanism that converts internal energy into kinetic energy is called an engine, and the form of an automobile engine is mainly an internal combustion engine with a cylinder and a piston as a conversion mechanism. According to the different fuel and ignition forms, it can be divided into gasoline engine or diesel engine, or there are engines fueled by hydrogen, natural gas, and petroleum gas, and the combustion form is less different from gasoline engines. According to the working cycle and piston stroke characteristics, it can be divided into two-stroke and four-stroke engines. Common automotive engines mainly include cylinders, pistons, piston connecting rods, crankshafts and other common components. Gasoline engine with in-cylinder direct injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com