Energy-saving door window made of composite material and being of two-channel structure

A composite material, dual-channel technology, applied in the field of dual-channel structure composite material energy-saving doors and windows, can solve the problems of unsatisfactory chemical resistance stability, large ratio of door and window frame to window area, poor thermal insulation performance and permeability of doors and windows, etc. Thermal insulation effect, fire resistance and weight improvement, thermal conductivity reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with specific embodiment, further illustrate the present invention.

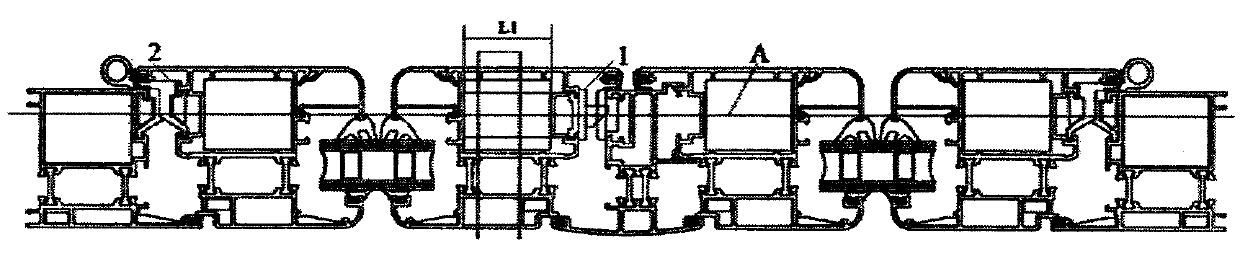

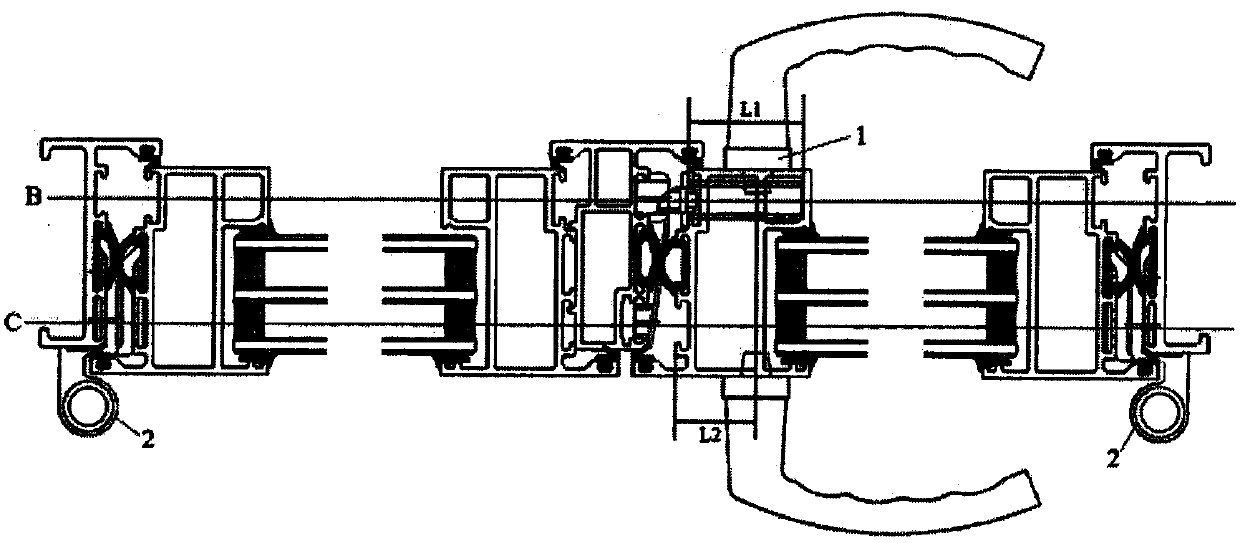

[0019] figure 1 The schematic diagram of the energy-saving door and window with double-channel structure composite material provided in this embodiment, the energy-saving door and window with double-channel structure composite material includes a door and window profile frame, and a lock 1 and a hinge 2 are installed on the door and window profile frame. The installation channel B of the lock 1 and the installation channel C of the hinge 2 are respectively located on the inner and outer sides of the door and window profile frame, and the installation channel B of the lock 1 and the installation channel C of the hinge 2 are not coaxially arranged, that is, the two are not on the same linear channel . The lock 1 and the hinge 2 do not affect each other when they are opened.

[0020] Since the length of the lock 1 is greater than that of the hinge 2, when the installation channel B...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com