Leveling device and method for fabricated floor

A prefabricated, cuboid technology, which is applied in the direction of construction, building structure, and building materials processing, can solve the problems of time-consuming and costly rework, poor leveling quality, and quality defects, and achieve simple production and installation, leveling and compactness , low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

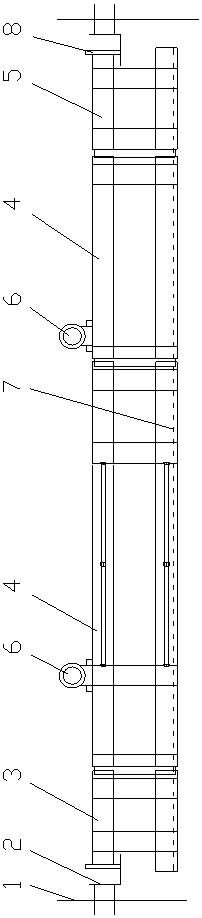

[0024] In order to better understand the present invention, below in conjunction with embodiment and accompanying drawing, technical scheme of the present invention is described further (as Figure 1-5 shown).

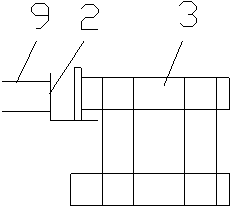

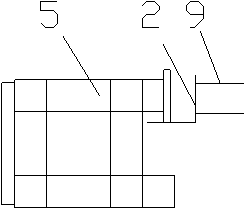

[0025] A prefabricated floor leveling device, which includes a pair of rails 2, one or more beam segments 4, falcon end segments 5 and shank end segments 3; the pair of rails 2 are respectively (horizontally) fixedly installed On the wall or column insert ribs 1 on both sides of the floor; the beam segment 4 is a cuboid structure, one end of which is a falcon, and the other end is a shank; the falcon end section 5 is a cuboid structure, one end of which is a falcon , the other end is provided with a track wheel 8; the shank end section 3 is a cuboid structure, one end is a shank, and the other end is provided with a track wheel 8; the one or more beam segments 4, the falcon end section 5 The shank end section 3 is assembled into an integral beam through the mortise an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com