Supporting bottom frame structure of spliced floor

A chassis and floor technology, applied in the direction of building structure, floor, building, etc., can solve the problems of low efficiency, heavy installation and operation workload, easy rust of bolts, etc., and achieve stable connection, high efficiency and high practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

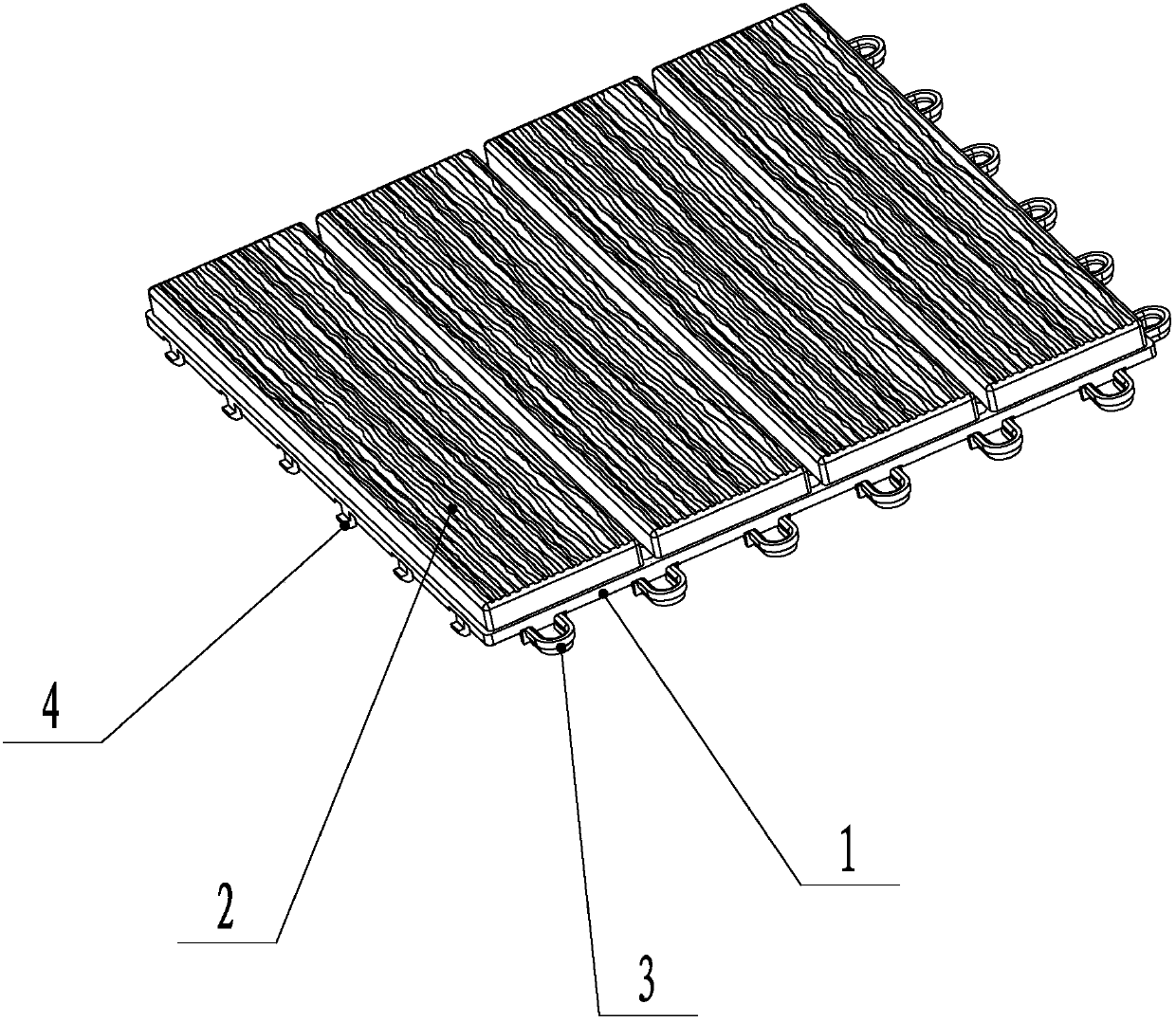

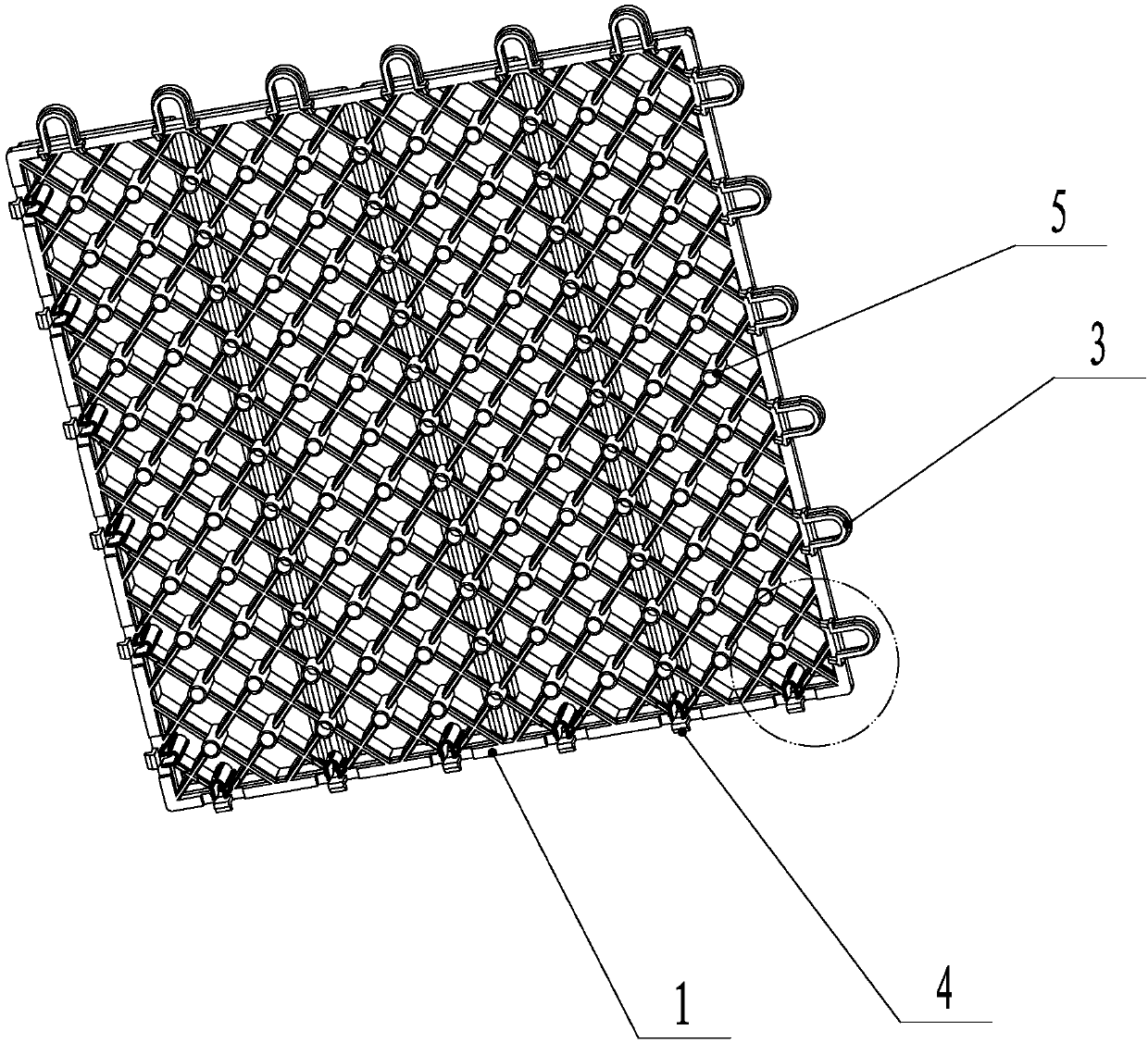

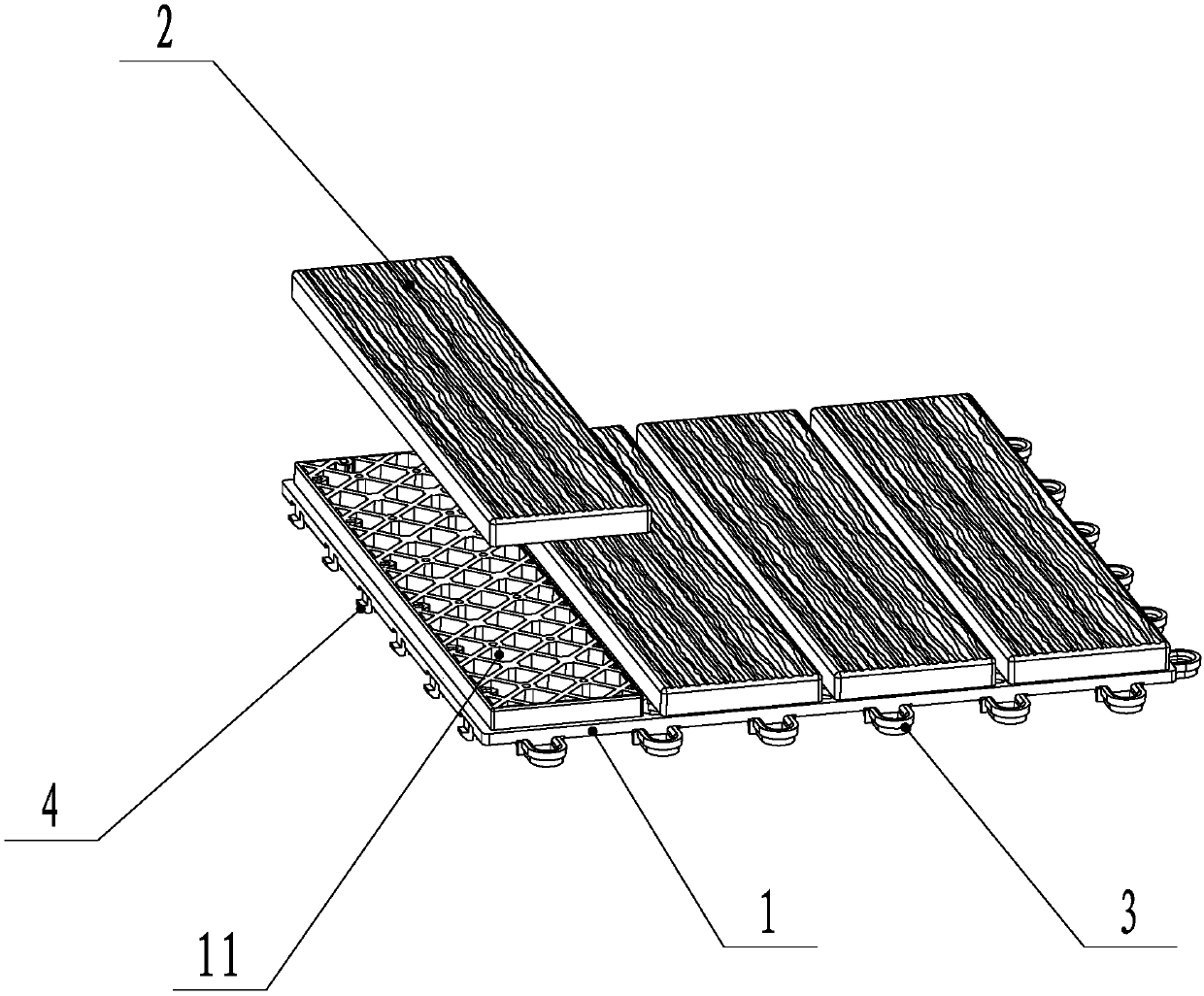

[0019] refer to Figure 1 to Figure 7 , a kind of assembly floor applying the present invention, comprising a quadrangular support base 1, the size of the support base 1 can be set according to actual needs, a plurality of imitation wood substrates 2 are installed on the support base 1, the support base 1 The materials of the frame 1 and the imitation wood base plate 2 are all selected as environmentally friendly plastics, and the color of the imitation wood base plate 2 adopts a color similar to that of logs, and in order to be more realistic, a wood grain can be formed on the upper end of the imitation wood base plate 2, and the support chassis The side of 1 is provided with a connecting portion connected with other assembled floors, and the bottom of the supporting chassis 1 is provided with evenly distributed supporting feet 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com