Prefabricated assembly-type balcony

A prefabricated assembly and balcony technology, applied to balconies, water supply devices, drinking water devices, etc., can solve the problems of not being able to make full use of solar energy, fail to achieve heat preservation effects, and easily damage the structure of balcony panels, so as to save power and improve Heat insulation effect, simple installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings, so as to help understand the content of the present invention.

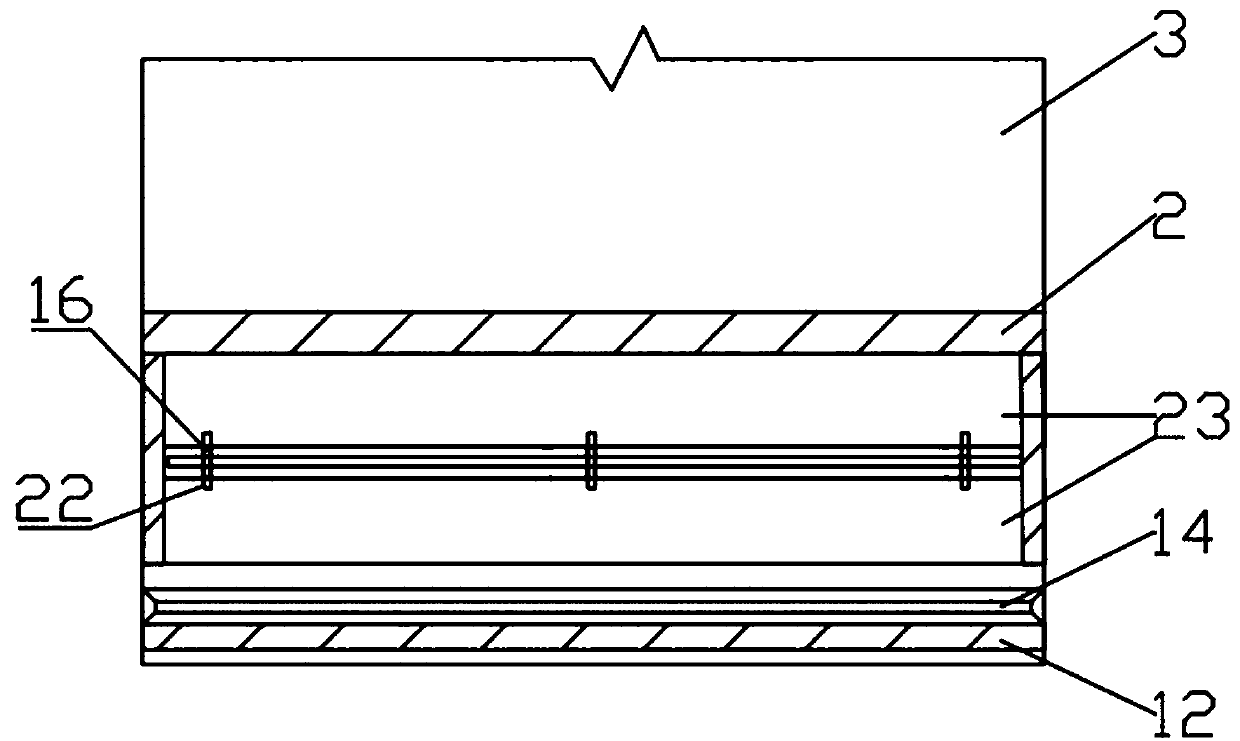

[0032] Figure 1-6A prefabricated balcony provided for the present invention includes a solar panel 1, a vertical baffle 2, a horizontal balcony panel 3 and a rainwater collection box 8, the vertical baffle 2 and the horizontal balcony panel 3 are vertically arranged, and the vertical baffle 2 passes through The steel structure and the horizontal balcony slab 3 are prefabricated as a whole, the inner side of the horizontal balcony slab 3 is fixed to the main body of the building, and the outer side of the horizontal balcony slab 3 is sequentially provided with a balcony opening 12, a first convex groove 13 and a second convex groove 15, solar panels 1 inclined setting, the slope of the rainwater collection pool 25 is 1%-2%, which is convenient for collecting rainwater into the rainwater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com