Inking uniform printing mechanism

A printing mechanism and uniform technology, which is applied in the direction of printing machines, printing, general parts of printing machinery, etc., can solve the problems of poor ink stirring effect, poor ink filling effect, uneven ink distribution, etc., to improve the ink filling effect, Good inking effect and good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

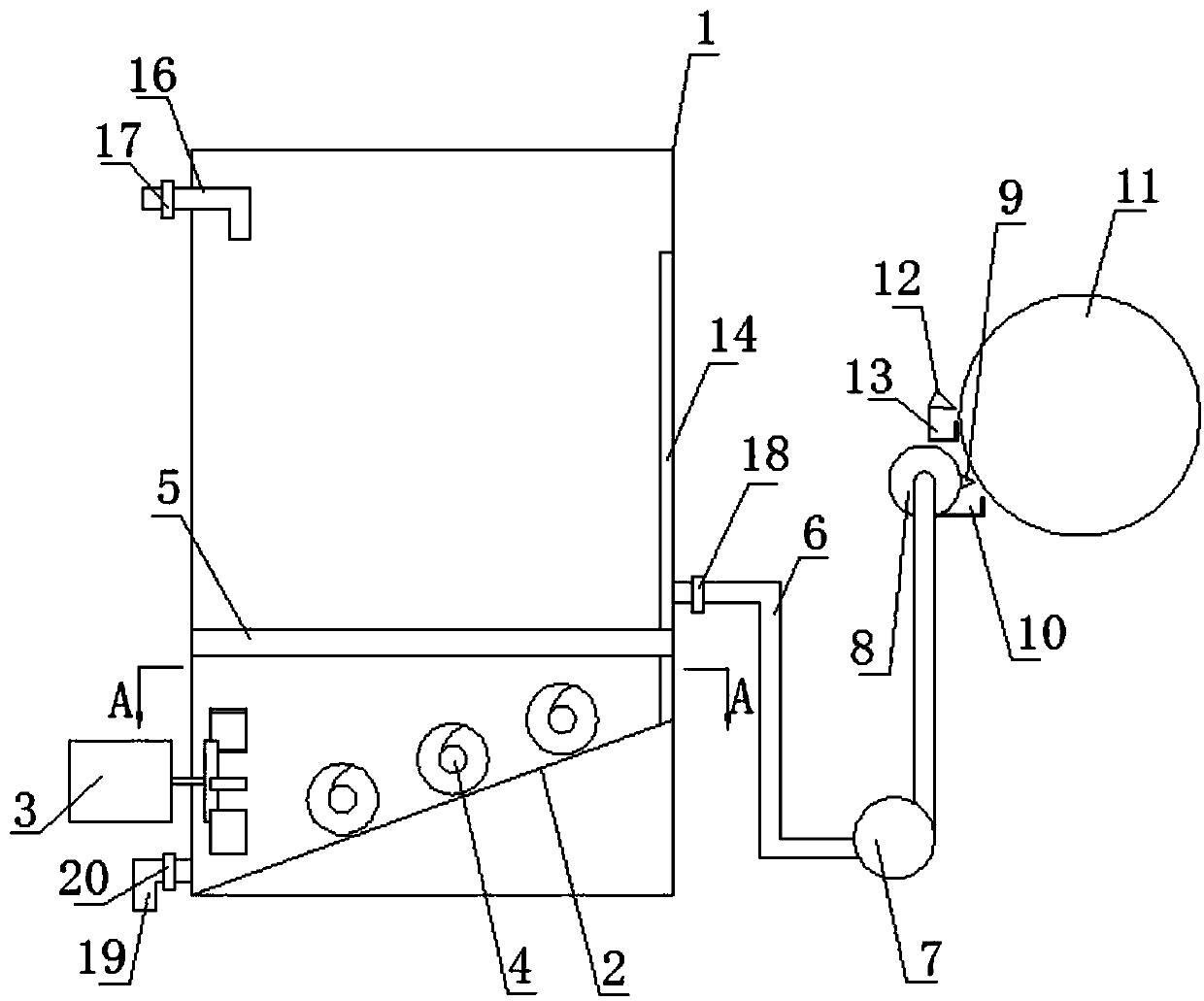

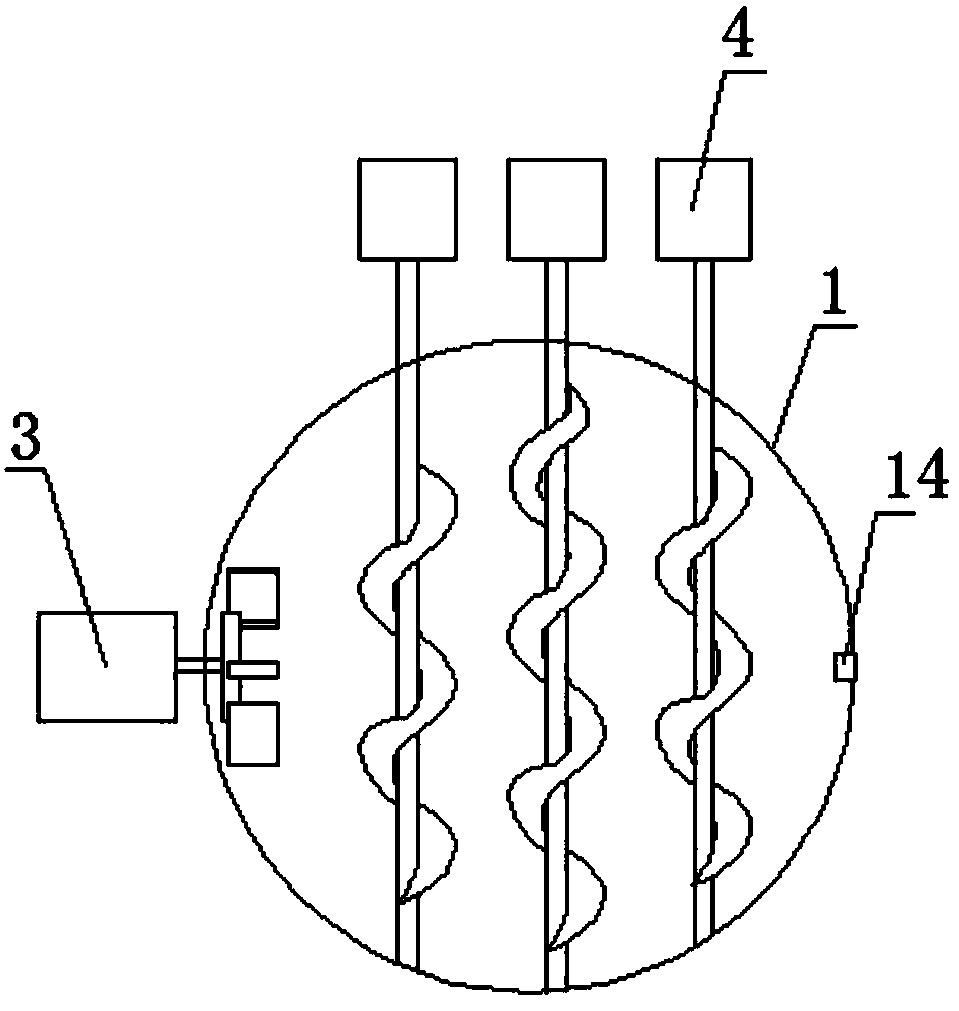

[0019] Example. A printing mechanism with uniform inking, constituted as Figures 1 to 5 As shown, the ink pool 1 is included, and the ink pool 1 is cylindrical; the bottom of the ink pool 1 is connected with a partition 2, and the partition 2 is inclined; the bottom of the ink pool 1 is connected with a turbine agitator 3, and the turbine The agitator 3 is located on the side of the partition plate 2 inclined downward; a grid plate 5 is arranged above the partition plate 2, and a plurality of ribbon agitators 4 are arranged between the partition plate 2 and the grid plate 5; One side of the ink pool 1 is connected with a feed pipe 6, and the feed pipe 6 is located above the grid plate 5; the feed pipe 6 is provided with a feed pump 7, and the feed pipe 6 is connected with an inkjet tube 8; Pipe 8...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com