A kind of preparation method of carbon-coated copper micro-nano particle composite material

A technology of micro-nano particles and composite materials, which is applied in the field of preparation of carbon-coated copper micro-nano particle composite materials, can solve the problems of restricting large-scale production, complex processing technology, and high equipment requirements, and achieves easy industrial implementation and simple equipment technology. , the effect of low cost

Active Publication Date: 2019-10-01

SHANGHAI INST OF TECH

View PDF7 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the above method requires high equipment, complicated follow-up treatment process, long reaction time, high energy consumption and extremely small output, which greatly limit the large-scale production of carbon-coated copper micro-nanoparticle composite materials.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

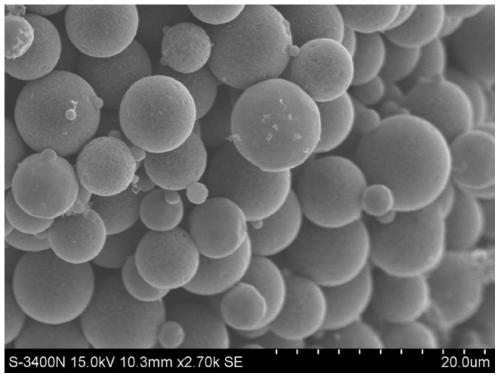

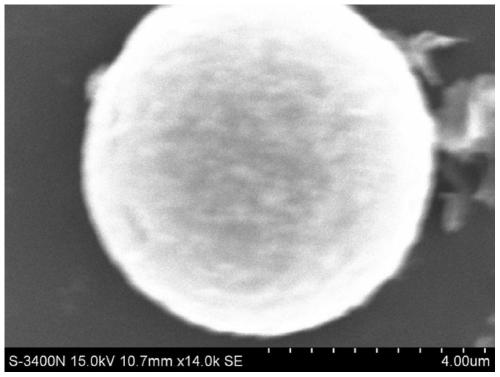

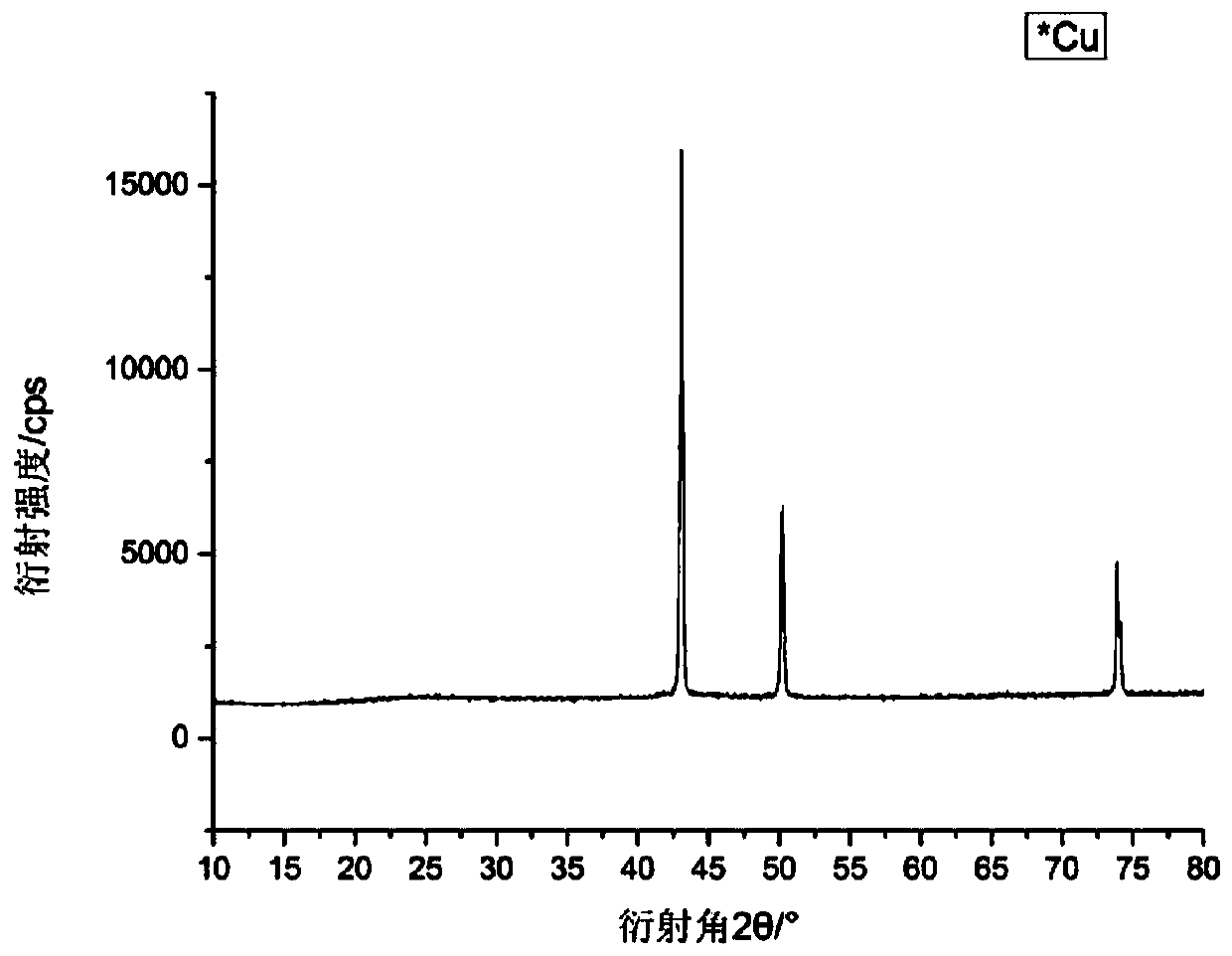

The invention discloses a preparation method of a carbon-coated copper micro-nano particle composite material. The invention adopts the method of combining hydrothermal synthesis and high-temperature carbonization to prepare carbon-coated copper micro-nano particle composite material. The compound obtained by the method has good carbon coating property, simple operation process, and is convenient for mass production.

Description

technical field The invention relates to a preparation method of a carbon-coated copper micro-nano particle composite material, which belongs to the technical field of carbon material synthesis. Background technique The core / shell nanostructure with inorganic or organic matter as the shell has excellent physical and chemical properties, which has aroused great interest of researchers. Among them, the carbon-coated metal (M / C) structure, especially Cu / C For example, due to their inexpensive and unique properties, they have been intensively studied for their wide applications in biosensors, supercapacitors, fuel cells, and catalysts, etc. After carbon coating, it not only retains the unique electromagnetic and optical properties of this Cu particle, but also endows it with better chemical stability, acid and alkali resistance, biocompatibility and surface functionalization. Microparticles can be modified to expand their wider applications. So far, many methods have been deve...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B22F1/02C23C18/12B82Y40/00B82Y30/00

CPCC23C18/1204C23C18/1241B82Y30/00B82Y40/00B22F1/16

Inventor 张大伟沈绍典王爱民王根礼毛东森卢冠忠

Owner SHANGHAI INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com