Plate feeding device

A technology for feeding devices and plates, applied in the directions of feeding devices, positioning devices, storage devices, etc., can solve problems such as feeding difficulties, and achieve the effect of solving feeding difficulties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

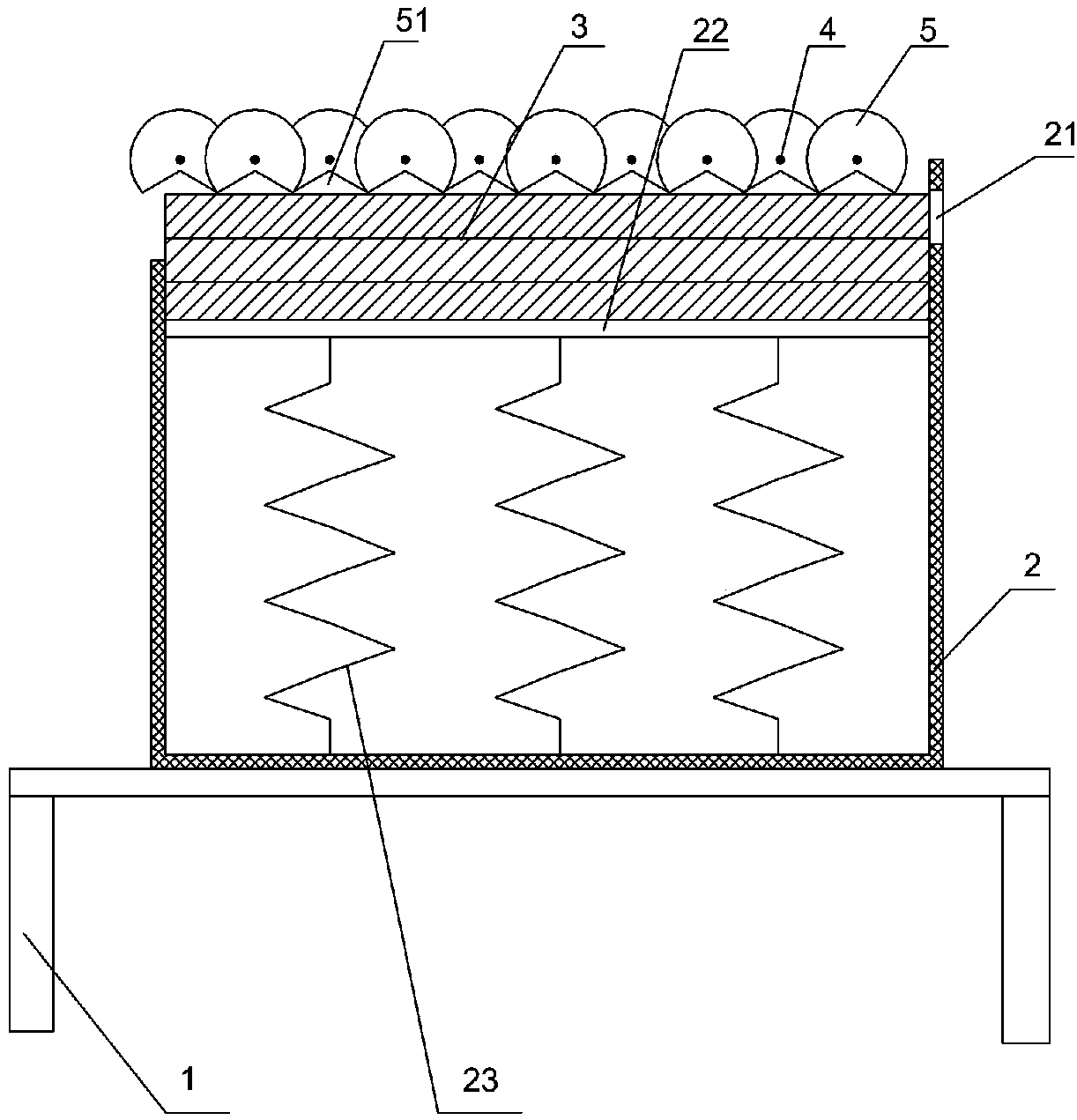

[0027] Such as figure 1 As shown, the sheet material feeding device of this embodiment includes a frame 1, a storage box 2 is installed on the frame 1, the upper part of the storage box 2 is open, and a tray 22 is slidingly arranged in the storage box 2, and the sheets 3 are stacked On the tray 22, there are three elastic supports connected between the bottom end of the tray 22 and the material storage box 2 for supporting the tray 22. The elastic supports are springs 23, and a discharge port 21 is provided on the right side wall of the material storage box 2. The discharge port 21 is tapered, with its large diameter end facing the outside of the material storage box 2 and its small diameter end facing the inside of the material storage box 2 .

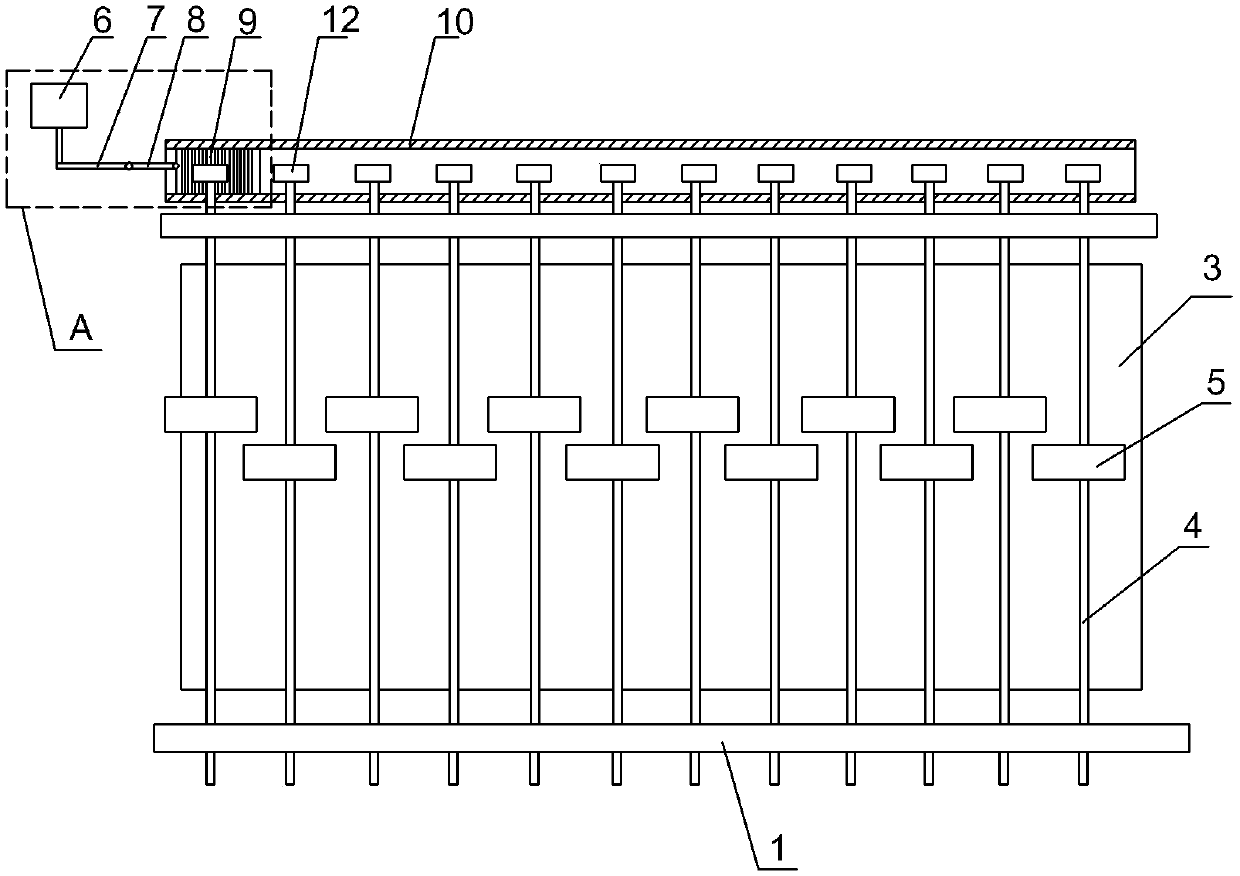

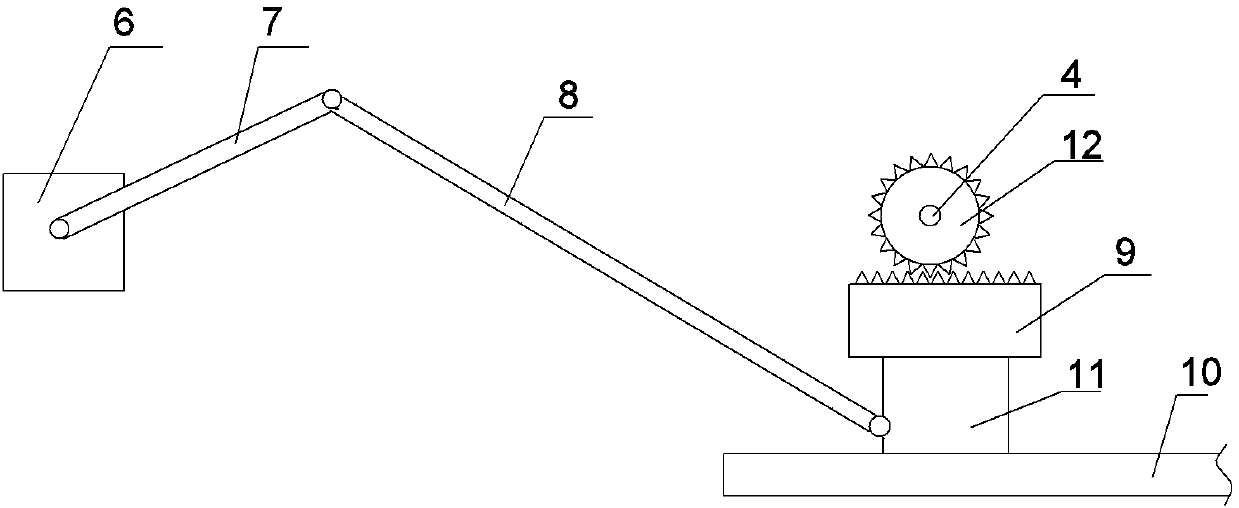

[0028] Such as figure 2 and image 3 As shown, the frame 1 is also provided with a material shifting mechanism for conveying the plate 3, the material shifting mechanism is located above the plate 3, the material shifting mechanism...

Embodiment 2

[0033] The difference between this embodiment and Embodiment 1 is that the number of runners 5 on the rotating shaft 4 is different. In this embodiment, the number of runners 5 on each rotating shaft 4 is three, and the three runners 5 are along the axis Evenly distributed.

[0034] Compared with Embodiment 1, this embodiment has the advantage that the three runners 5 can evenly apply pressure to the side wall of the plate 3 in the lateral direction of the plate 3, which can make the movement of the plate 3 more stable on the one hand, and can also make the plate 3 move more smoothly on the other hand. 3 Movement is easier.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com