Plant Fiber Loading Modified Nano Titanium Dioxide Composite Material and Its Preparation and Application

A technology of nano-titanium dioxide and plant fiber, which is applied in the direction of catalyst activation/preparation, organic compound/hydride/coordination complex catalyst, physical/chemical process catalyst, etc. It can solve difficult separation and recovery, inability to make full use of solar energy, and easy agglomeration Inactivation and other issues, to achieve great development prospects, improve the effect of a narrow range of light response and a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1 Preparation method of plant fiber loaded modified nano titanium dioxide composite material

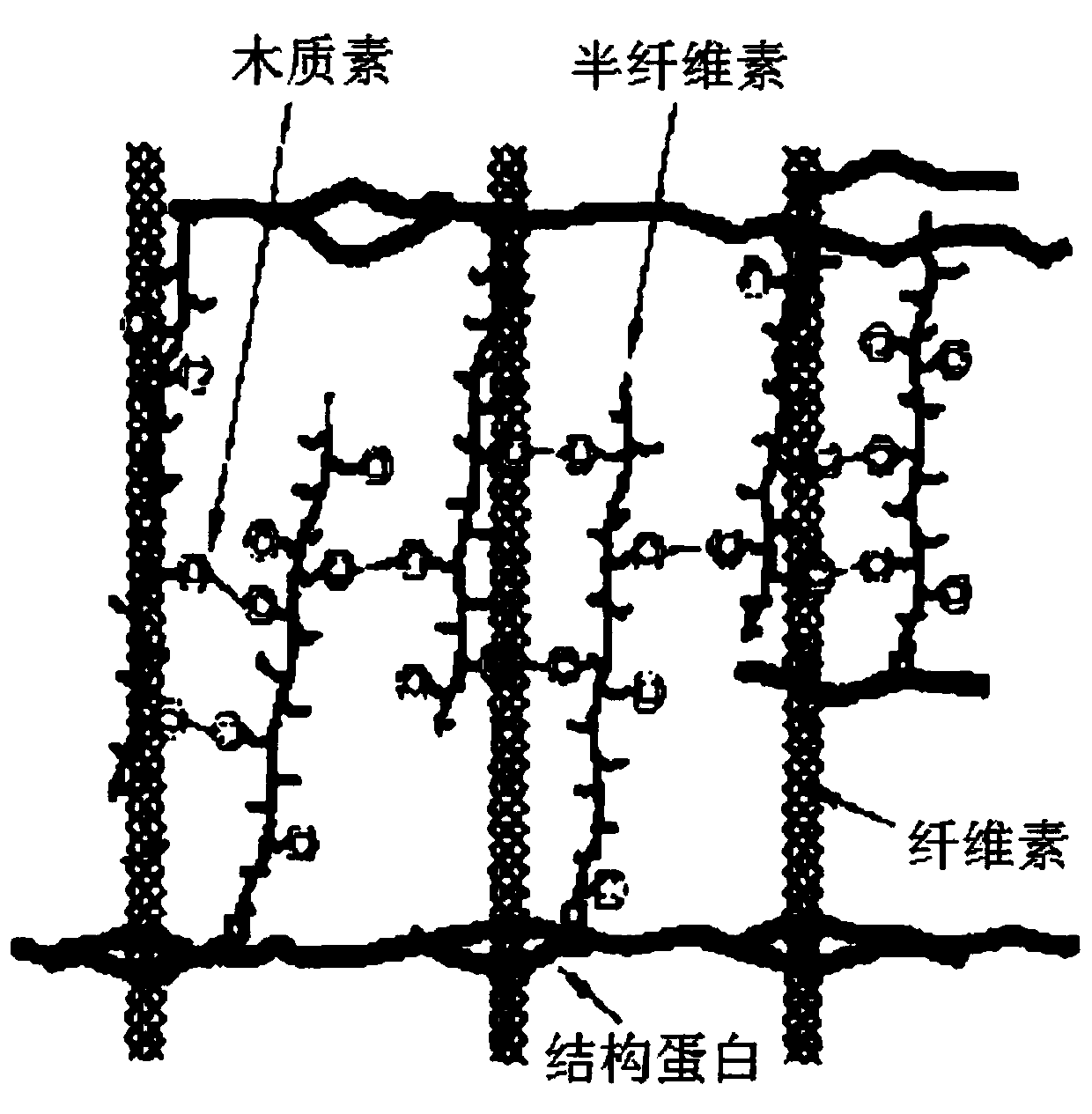

[0033] (1) Select one or a mixture of bamboo, reed, rice straw, wheat straw, etc., and remove non-fibrous components such as lignin after polishing treatment, and immerse the obtained cellulose component in distilled water and put it in an oven. Slowly heat to 120°C and take it out after one hour. After it cools to room temperature, wash it with deionized water, then put it in an oven, slowly heat it to 100°C, take it out one hour later, crush and sieve to obtain plant fiber.

[0034] (2) Purifying the plant fiber obtained in step (1) to further remove pectin, gum and other impurities in the plant fiber. Firstly, the plant fiber is immersed in boiling water for 1 min, and then 5g / L H 2 O 2 And 4g / L Na 2 SiO 3 Perform oxygen bleaching, then rinse with water, rinse with boiling water for 2 minutes, then rinse with deionized water 3 times, then put it in an oven, slowly heat t...

Embodiment 2

[0041] Example 2 Preparation method of plant fiber loaded modified nano titanium dioxide composite material

[0042] (1) Select one or a mixture of bamboo, reed, rice straw, wheat straw, etc., and remove non-fibrous components such as lignin after polishing treatment, and immerse the obtained cellulose component in distilled water and put it in an oven. Slowly heat to 120°C and take it out after one hour. After it cools to room temperature, wash it with deionized water, then put it in an oven, slowly heat it to 100°C, take it out one hour later, crush and sieve to obtain plant fiber.

[0043] (2) Purifying the plant fiber obtained in step (1) to further remove pectin, gum and other impurities in the plant fiber. Firstly, the plant fiber is immersed in boiling water for 1 min, and then 5g / L H 2 O 2 And 4g / L Na 2 SiO 3 Perform oxygen bleaching, then rinse with water, rinse with boiling water for 2 minutes, then rinse with deionized water 3 times, then put it in an oven, slowly heat t...

Embodiment 3

[0050] Example 3 Preparation method of plant fiber loaded modified nano titanium dioxide composite material

[0051] (1) Select one or a mixture of bamboo, reed, rice straw, wheat straw, etc., and remove non-fibrous components such as lignin after polishing treatment, and immerse the obtained cellulose component in distilled water and put it in an oven. Slowly heat to 120°C and take it out after one hour. After it cools to room temperature, wash it with deionized water, then put it in an oven, slowly heat it to 100°C, take it out one hour later, crush and sieve to obtain plant fiber.

[0052] (2) Purifying the plant fiber obtained in step (1) to further remove pectin, gum and other impurities in the plant fiber. Firstly, the plant fiber is immersed in boiling water for 1 min, and then 5g / L H 2 O 2 And 4g / L Na 2 SiO 3 Perform oxygen bleaching, then rinse with water, rinse with boiling water for 2 minutes, then rinse with deionized water 3 times, then put it in an oven, slowly heat t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com