Sandwich structure paper diaper flow guiding layer material and preparation method thereof

A technology for diapers and sandwiches, which is applied in the field of preparation of the diversion layer of diapers with a sandwich structure. It can solve the problems of poor air permeability and inability to effectively guide the longitudinal diffusion of liquid, and achieve short penetration time, short liquid penetration time, and large liquid The effect of storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

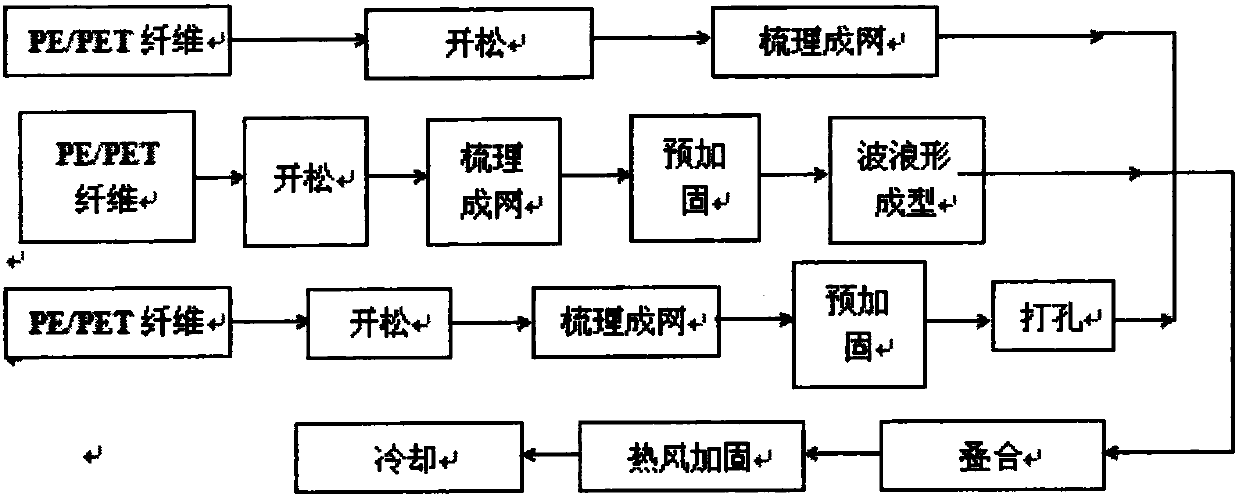

[0049] Such as Figure 10 As shown, the sandwich structure diaper diversion layer material is composed of three-layer sheets, all of which are non-woven fabrics made of chemical fibers through hot air penetration bonding non-woven technology, and the three-layer sheets Laminated and bonded from top to bottom to form a sandwich structure; the upper sheet 1 is such as figure 2 Machine direction oriented web as shown; middle layer sheet 2 is as Figure 7 The longitudinally oriented fiber web shown has a wavy cross-section; the lower sheet 3 is as image 3 The messy web shown, such as Figure 9As shown, uniform small holes 4 are distributed on the fiber net; the chemical fibers are ES fibers. The ES fiber is a sheath-core bicomponent fiber, wherein the sheath layer is PE, and the core layer is PP or PET. The crimp of the ES fiber is 10 pieces / 25mm. The surface density of the sandwich structure diaper diversion layer material is 30g / m 2 , the thickness is 4mm.

[0050] Such...

Embodiment 2

[0057] Such as Figure 10 As shown, the sandwich structure diaper diversion layer material is composed of three-layer sheets, all of which are non-woven fabrics made of chemical fibers through hot air penetration bonding non-woven technology, and the three-layer sheets Laminated and bonded from top to bottom to form a sandwich structure; the upper sheet 1 is such as figure 2 Machine direction oriented web as shown; middle layer sheet 2 is as Figure 8 The longitudinally oriented fiber web shown has a zigzag cross section; the lower sheet 3 is as image 3 The messy web shown, such as Figure 9 As shown, uniform small holes 4 are distributed on the fiber net; the chemical fibers are ES fibers. The ES fiber is a sheath-core bicomponent fiber, wherein the sheath layer is PE, and the core layer is PP or PET. The crimp of the ES fiber is 12 pieces / 25mm. The surface density of the sandwich structure diaper diversion layer material is 30g / m 2 , the thickness is 3mm.

[0058] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com