Preparation method of low-sugar chickpea soymilk

A technology of chickpea and soybean milk, which is applied in the field of preparation of low-sugar chickpea soybean milk, can solve the problems of low sugar content and low cost, and achieve the effect of smooth taste, good stability and rich chickpea aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

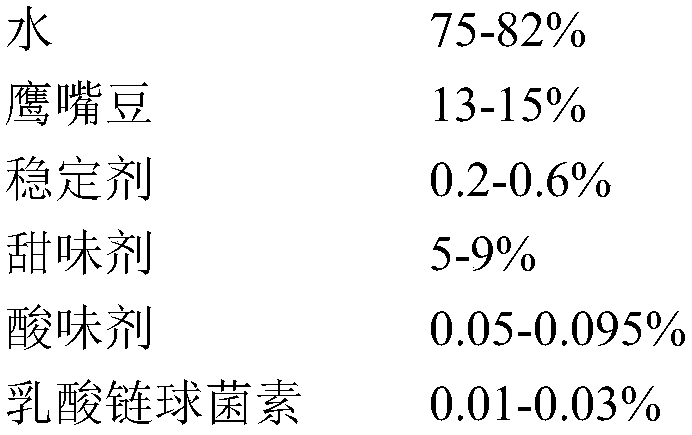

[0024] The raw materials are as follows:

[0025]

[0026] 1. Soaking and cleaning: add 4 times the weight of NaHCO containing 0.2% at 25°C 3 Soak the chickpeas in water for 12 hours until the chickpeas are completely softened. Then wash 3-5 times until the rinse water is clear and transparent.

[0027] 2. Pre-grinding: Drain the cleaned chickpeas, add 7 times the amount of water at a temperature of 55°C, adjust the pH to 7, and grind with a refiner for 6 minutes.

[0028] 3. Filtration: Filter with a 200-mesh sieve to remove the larger particles that have not been ground to obtain a uniform and fine puree.

[0029] 4. Enzyme treatment: adjust the pH value of the filtrate to 7.0, add 0.45% α-amylase at 65° C., and perform enzymatic hydrolysis for 20 minutes to enzymatically hydrolyze most of the chickpea starch.

[0030] 5. Blending: add 3% sucrose, 3% xylitol, 0.03% citric acid and 0.03% lactic acid for flavoring; and add 0.15% xanthan gum, 0.25% sodium carboxymethyl ce...

Embodiment 2

[0036] The raw materials are as follows:

[0037]

[0038]

[0039] 1. Soaking and cleaning: add 4 times the weight of NaHCO containing 0.2% at 25°C 3 Soak the chickpeas in water for 12 hours until the chickpeas are completely softened. Then wash 3-5 times until the rinse water is clear and transparent.

[0040] 2. Pre-grinding: Drain the cleaned chickpeas, add 6 times the amount of water at a temperature of 55°C, adjust the pH to 7, and grind with a refiner for 6 minutes.

[0041] 3. Filtration: Filter with a 200-mesh sieve to remove the larger particles that have not been ground to obtain a uniform and fine puree.

[0042] 4. Enzyme treatment: adjust the pH value of the filtrate to 7.0, add 0.4% α-amylase at 65° C., and perform enzymatic hydrolysis for 20 minutes to enzymolyze most of the chickpea starch.

[0043] 5. Blending: Add 3% sucrose, 4% xylitol, 0.03% citric acid and 0.03% lactic acid for flavoring; and add 0.12% xanthan gum, 0.22% sodium carboxymethyl cell...

Embodiment 3

[0049] The raw materials are as follows:

[0050]

[0051] 1. Soaking and cleaning: at 25° C., add 4 times by weight of NaHCO3 water containing 0.2% to soak the chickpeas for 12 hours until the chickpeas are completely softened. Then wash 3-5 times until the rinse water is clear and transparent.

[0052] 2. Pre-grinding: Drain the cleaned chickpeas, add 6 times the amount of water at a temperature of 55°C, adjust the pH to 7, and grind with a refiner for 6 minutes.

[0053] 3. Filtration: Filter with a 200-mesh sieve to remove the larger particles that have not been ground to obtain a uniform and fine puree.

[0054] 4. Enzyme treatment: adjust the pH value of the filtrate to 7.0, add 0.4% α-amylase at 65° C., and perform enzymatic hydrolysis for 20 minutes to enzymolyze most of the chickpea starch.

[0055] 5. Blending: add 3% sucrose, 4% xylitol, 0.03% citric acid and 0.04% lactic acid for flavoring; and add 0.15% xanthan gum, 0.25% sodium carboxymethyl cellulose, propo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com