Method for improving lamination strength of lamination components

A component and strength technology, applied in chemical instruments and methods, lamination devices, optics, etc., can solve the problem of low bonding strength, and achieve the effect of avoiding glue shortage, improving bonding strength, and reducing the risk of degumming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

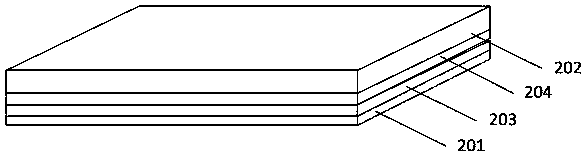

[0020] like figure 2 shown.

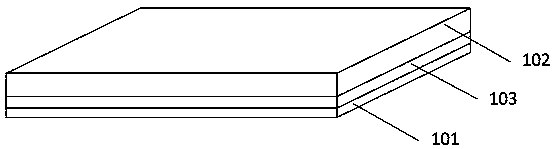

[0021] A method for improving the lamination strength of the lamination components. The liquid crystal screen is used as the lamination assembly A, and the glass is the lamination assembly B as an example. The lamination process adopted is: coating a certain Thickness of the water glue, after the water glue 203, 204 is cured to form the dry glue layer A and the dry glue layer B, then the liquid crystal screen 201 and the glass 202 are bonded to complete the double-sided dry glue bonding process. Due to the fluidity of the water glue, it has good contact with the bonding surface of the bonding component during coating, and the final bonding is that the dry glue layer A203 is bonded with the dry glue layer B204, and the performance of the same material is the same, except After foaming, it can be regarded as the same adhes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com