Ultrasonic measurement simulation test device for thickness of cylinder oil film in working process of diesel engine

A technology of working process and simulation test, which is applied in the direction of measuring devices, using ultrasonic/sonic/infrasonic waves, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention is described in more detail below in conjunction with accompanying drawing example:

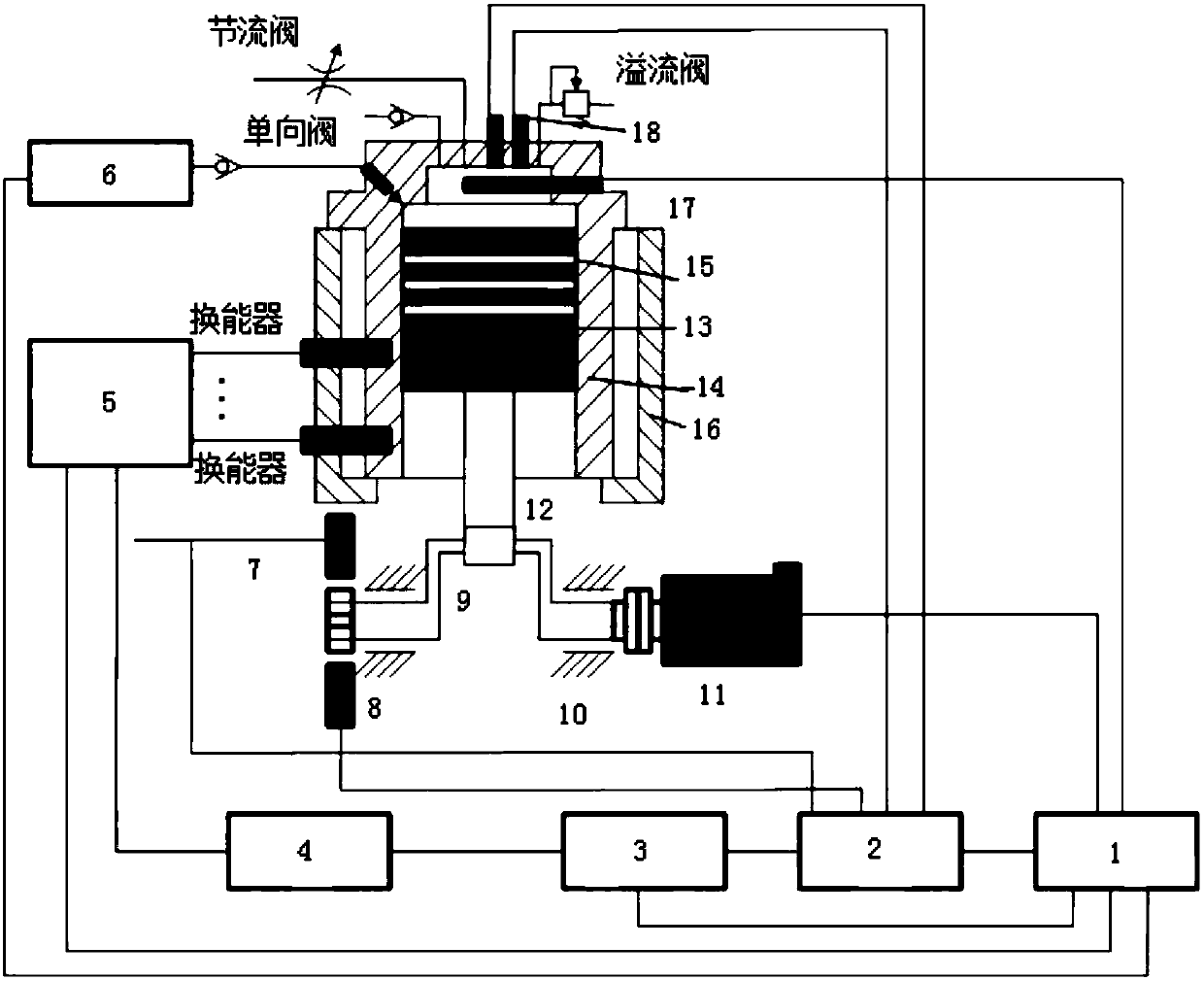

[0017] combine figure 1 The measurement system of the present invention includes a display and controller 1, a data collector 2, a pulse generator / receiver 3, a signal amplifier 4, a multiplexing switch 5, a transducer, a temperature sensor 18, a pressure sensor, a position sensor 8, Motor 11, cylinder liner 14, crankshaft 9, relief valve, check valve, throttle valve, oil injection system 6, heater 17, transducer, piston 13, piston ring 15, water jacket 16, connecting rod 12, crankshaft 9. Coupling 10 and other components.

[0018] Piston ring 15, piston 13, cylinder liner 14, connecting rod 12, crankshaft 9, water jacket 16 form a diesel engine basic cylinder piston structure. The coupling 10 connects the motor 11 and the crankshaft 9. Under the instructions of the display and the controller 1, the motor 11 drives the crankshaft 9 to rotate and drags the piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com