Sectional type air draft device used for laser cutting machine tool body

A laser cutting machine and ventilation device technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of high production cost, low ventilation efficiency, difficult maintenance, etc., and achieve easy installation and maintenance, simple structure, and ventilation good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

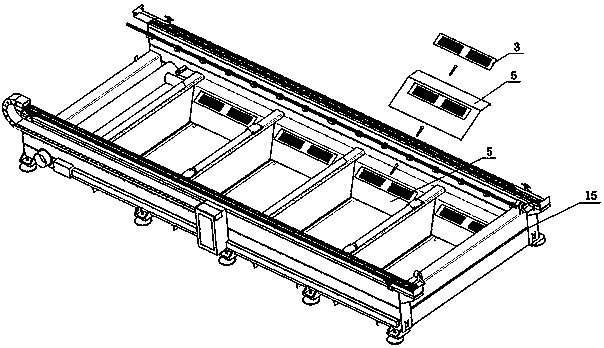

[0020] Such as figure 1 As shown, it is a structural schematic diagram of the segmented air exhaust device of the present invention installed on the laser cutting machine body. The segmented air exhaust device is fixed on the air exhaust panel 5 of the laser cutting machine body 15 by screws, and the exhaust air panel 5 is bent from sheet metal. The structure is fixed to the laser cutting machine body 15 by screws or welding, and is sealed and connected with the exhaust fan, so as to complete the extraction of the waste residue and exhaust gas formed in the cutting area of the laser cutting machine body 15.

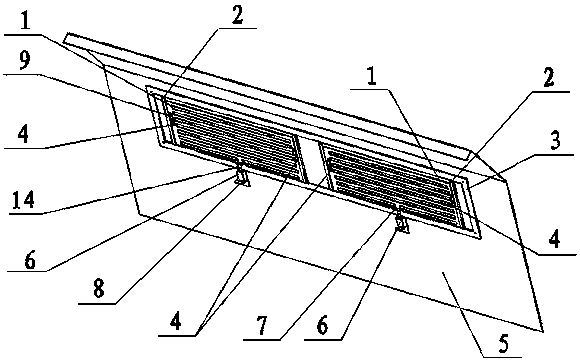

[0021] Such as figure 2 As shown, it is a schematic diagram of the overall structure of a segmented air exhaust device for a laser cutting machine body according to the present invention.

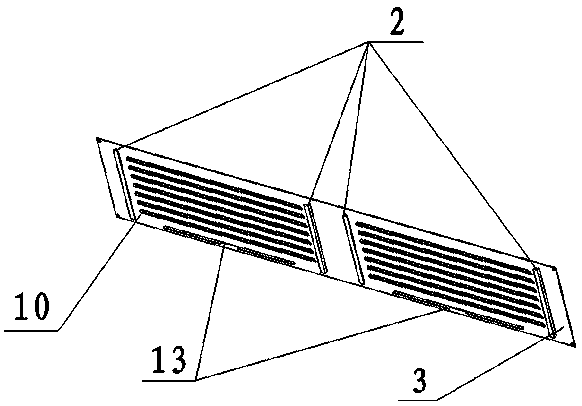

[0022] Such as image 3 As shown, it is a structural schematic diagram of the louver structure plate. The louver structure plate 3 is provided with a moving track 2, a louver air ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com