Soil pre-selecting and fertilizer mixing stirring equipment

A mixing equipment and mixing technology, which are applied to mixer accessories, mixers with rotating mixing devices, mixers, etc., can solve problems such as inability to adjust, affect mixing efficiency and mixing effect, and inability to mix blanking board materials, and improve the The effect of stirring, the effect of improving the feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

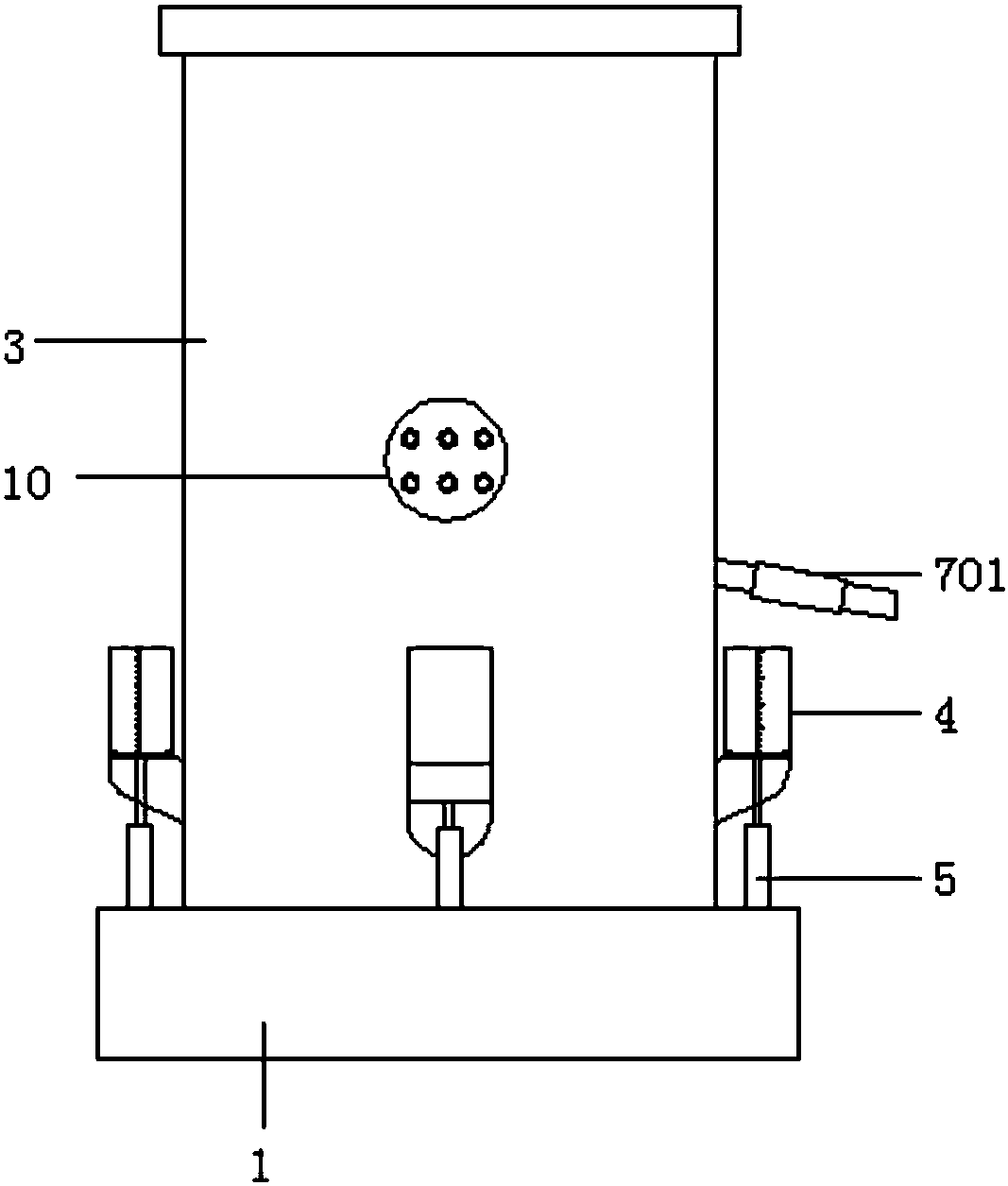

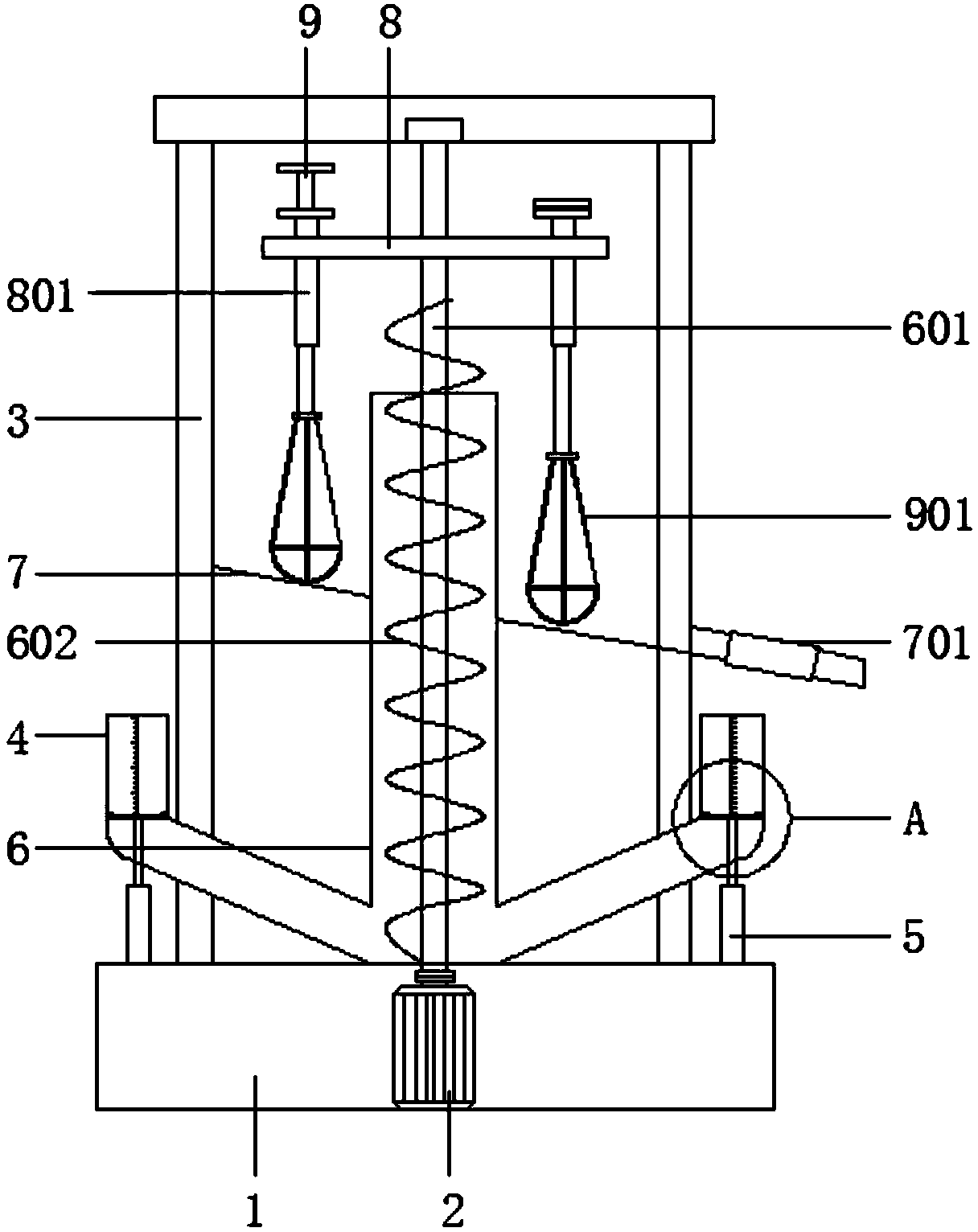

[0031] as attached figure 1 to the attached Figure 8 shown:

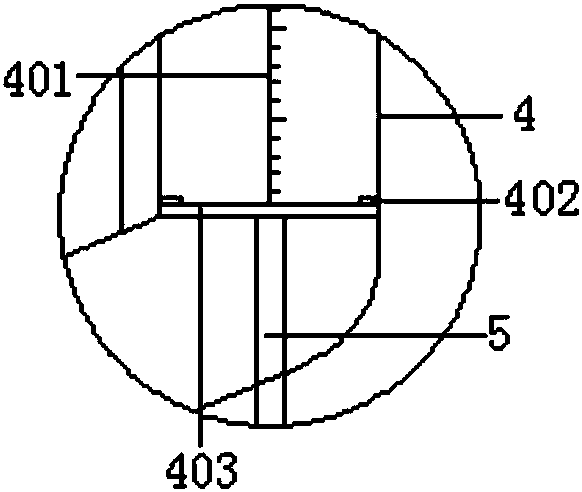

[0032] The present invention provides a soil pre-selection and mixing fertilizer mixing equipment, comprising a base 1, a motor 2, a casing 3, a feeding pipe 4, a scale line 401, an annular limit plate 402, a feeding baffle 403, an electric push rod 5, Lifting barrel 6, first rotating shaft 601, screw conveying blade 602, blanking plate 7, discharge pipe 701, turntable 8, linear rotating bush 801, second rotating shaft 9, stirring cage 901, ball 902, circular plate 903 and control Panel 10; a motor 2 is embedded in the inner cavity of the base 1, and the rotating shaft of the motor 2 and the first rotating shaft 601 are connected by a coupling, the shell 3 is arranged on the top of the base 1, and the material is fed The pipe 4 penetrates through the inner cavity of the shell 3 and communicates with the lifting bucket 6. An annular limit plate 402 is fixedly arranged on the inner side of the straight pipe section...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com