Detergent preparation machine for maintenance of instruments

An instrumentation and cleaning agent technology, which is applied to chemical instruments and methods, mixers, shaking/oscillating/vibrating mixers, etc., can solve the problem of inability to collect and use cleaning agents, save manpower, and prevent multi-stage cleaning agent raw materials Mixing preparation and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

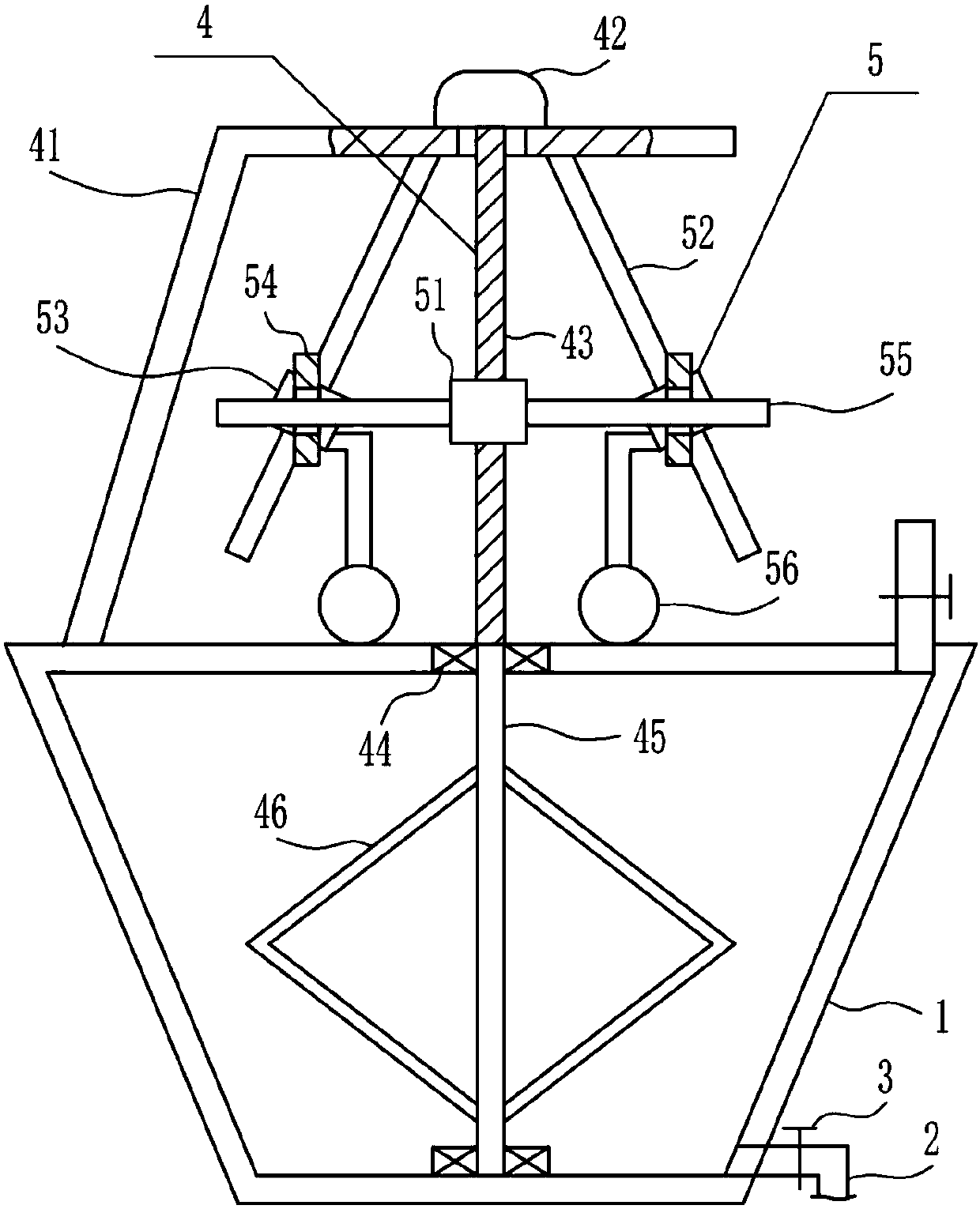

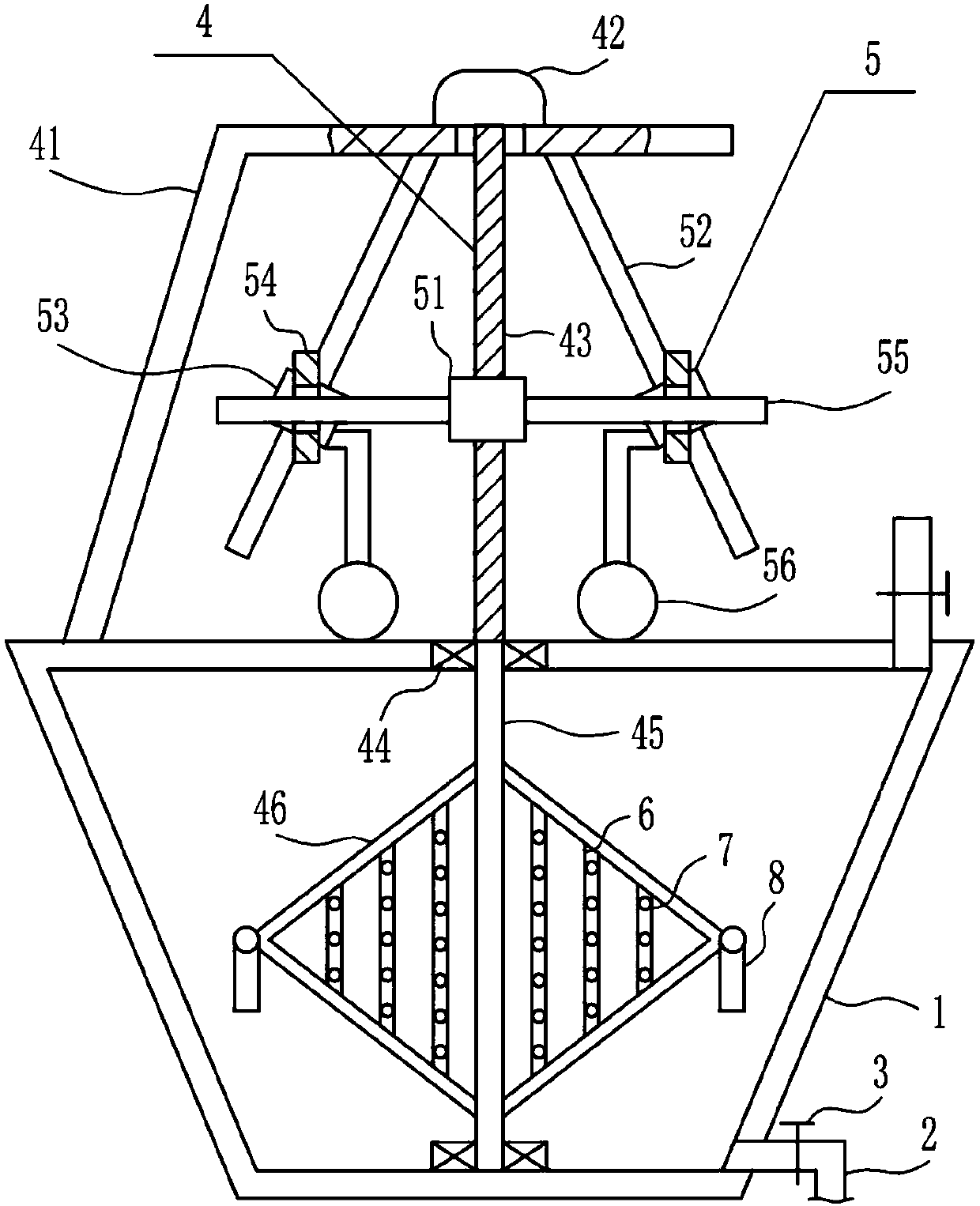

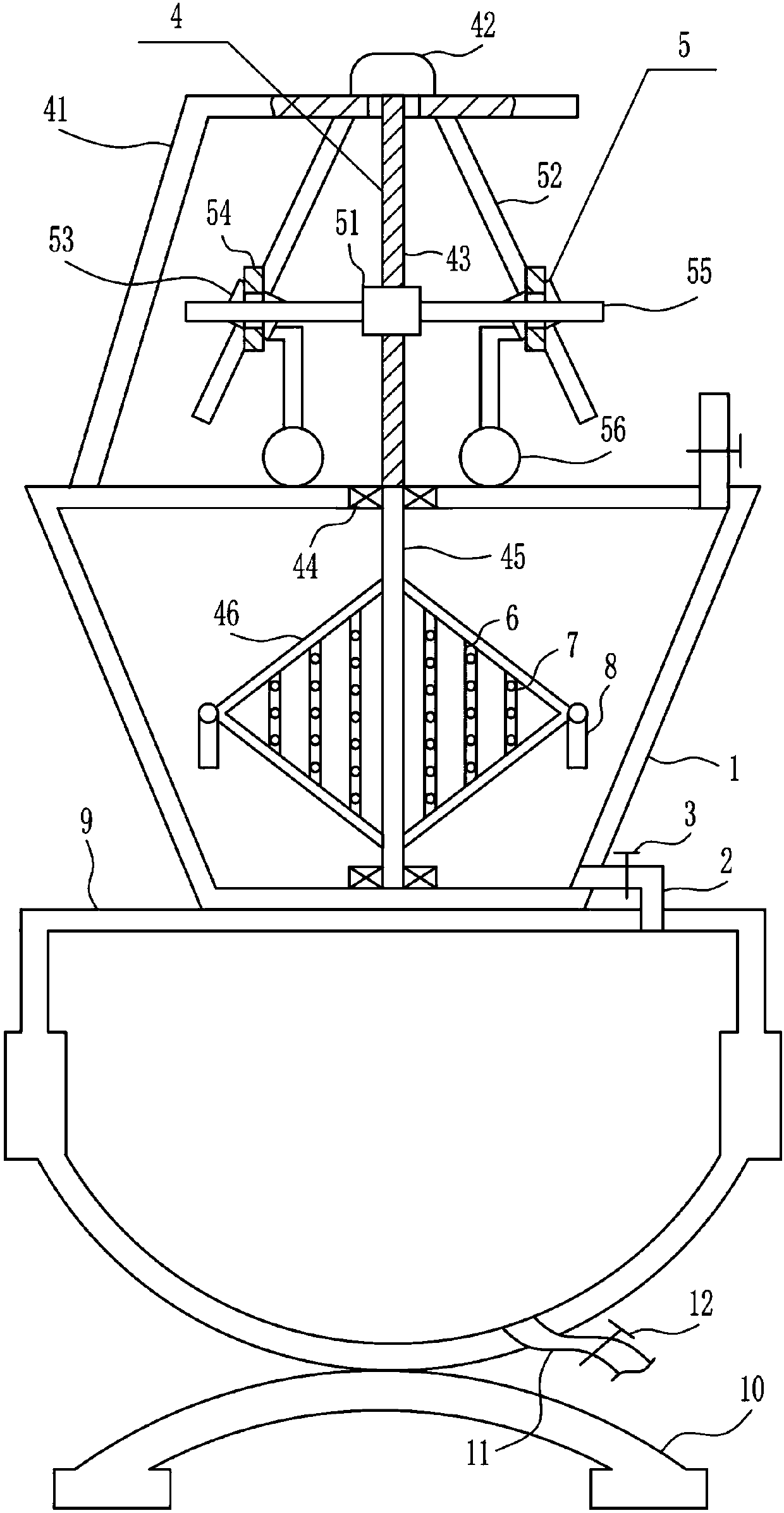

[0032] A cleaning agent preparation machine for instrumentation maintenance, such as Figure 1-5 As shown, it includes a preparation box 1, a first liquid outlet pipe 2, a first valve 3, a preparation mechanism 4, a preparation mechanism 4 and a beating mechanism 5. The lower part of the right side of the preparation box 1 is connected with the first liquid outlet pipe 2, and the first The outlet pipe 2 is provided with a first valve 3, the top of the preparation box 1 is connected with a preparation mechanism 4, and the preparation mechanism 4 is connected with a beating mechanism 5.

Embodiment 2

[0034] A cleaning agent preparation machine for instrumentation maintenance, such as Figure 1-5 As shown, it includes a preparation box 1, a first liquid outlet pipe 2, a first valve 3, a preparation mechanism 4, a preparation mechanism 4 and a beating mechanism 5. The lower part of the right side of the preparation box 1 is connected with the first liquid outlet pipe 2, and the first The outlet pipe 2 is provided with a first valve 3, the top of the preparation box 1 is connected with a preparation mechanism 4, and the preparation mechanism 4 is connected with a beating mechanism 5.

[0035] The preparation mechanism 4 includes a mounting plate 41, a servo motor 42, a screw 43, a first bearing seat 44, a first rotating rod 45, and a stirring rod 46. The left side of the top of the preparation box 1 is connected with a mounting plate 41, and the top of the mounting plate 41 is connected in the middle. There is a servo motor 42, the output shaft of the servo motor 42 is connec...

Embodiment 3

[0037] A cleaning agent preparation machine for instrumentation maintenance, such as Figure 1-5 As shown, it includes a preparation box 1, a first liquid outlet pipe 2, a first valve 3, a preparation mechanism 4, a preparation mechanism 4 and a beating mechanism 5. The lower part of the right side of the preparation box 1 is connected with the first liquid outlet pipe 2, and the first The outlet pipe 2 is provided with a first valve 3, the top of the preparation box 1 is connected with a preparation mechanism 4, and the preparation mechanism 4 is connected with a beating mechanism 5.

[0038] The preparation mechanism 4 includes a mounting plate 41, a servo motor 42, a screw 43, a first bearing seat 44, a first rotating rod 45, and a stirring rod 46. The left side of the top of the preparation box 1 is connected with a mounting plate 41, and the top of the mounting plate 41 is connected in the middle. There is a servo motor 42, the output shaft of the servo motor 42 is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com