Peanut hulling equipment

A kind of equipment, peanut technology, applied in the field of agricultural machinery, can solve the problems of inconvenience of eating, easily injured fingers, unable to meet the needs of ordinary families, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to further understand the invention content, characteristics and effects of the present invention, the following embodiments are listed below, and detailed descriptions are as follows in conjunction with the accompanying drawings.

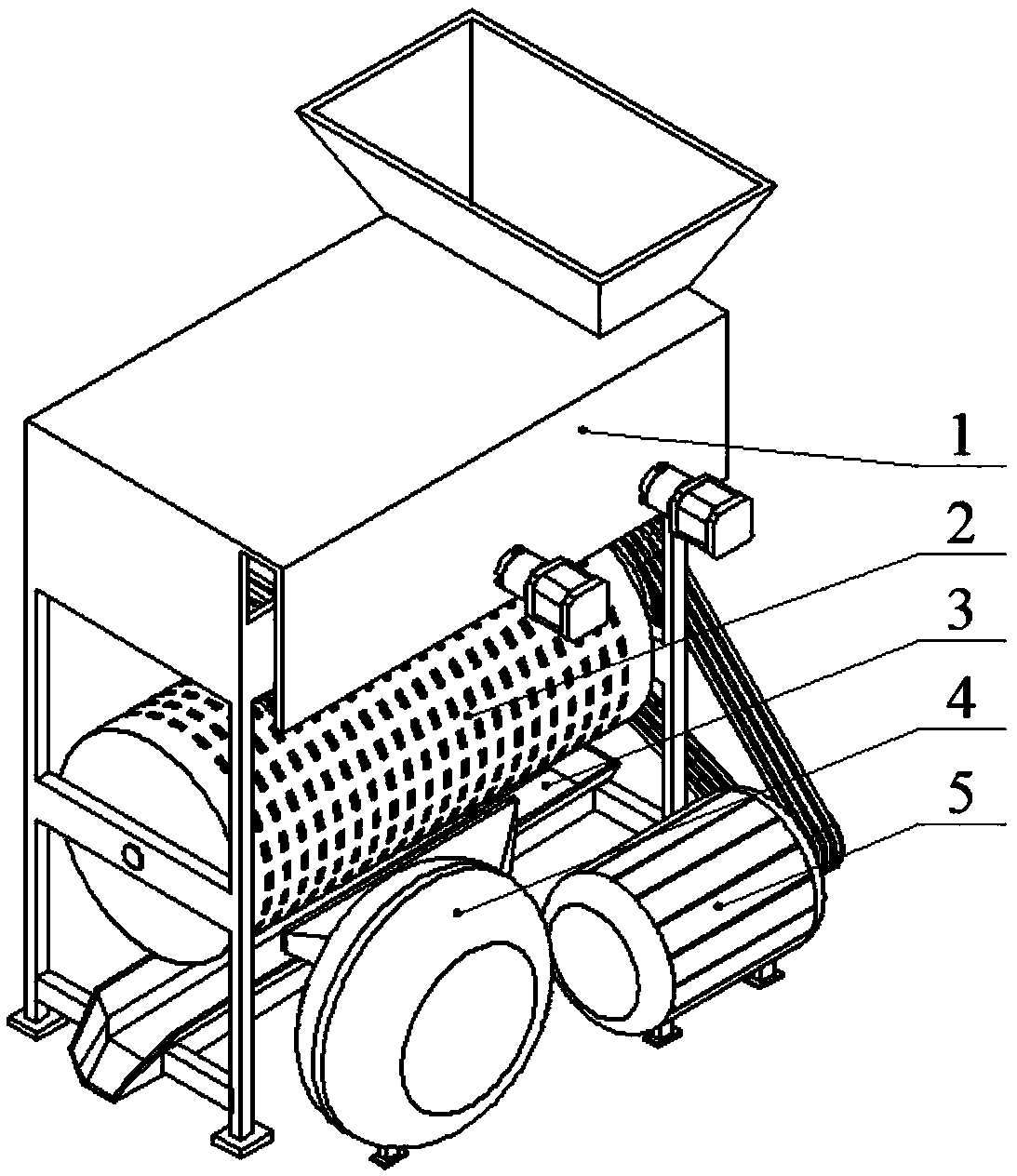

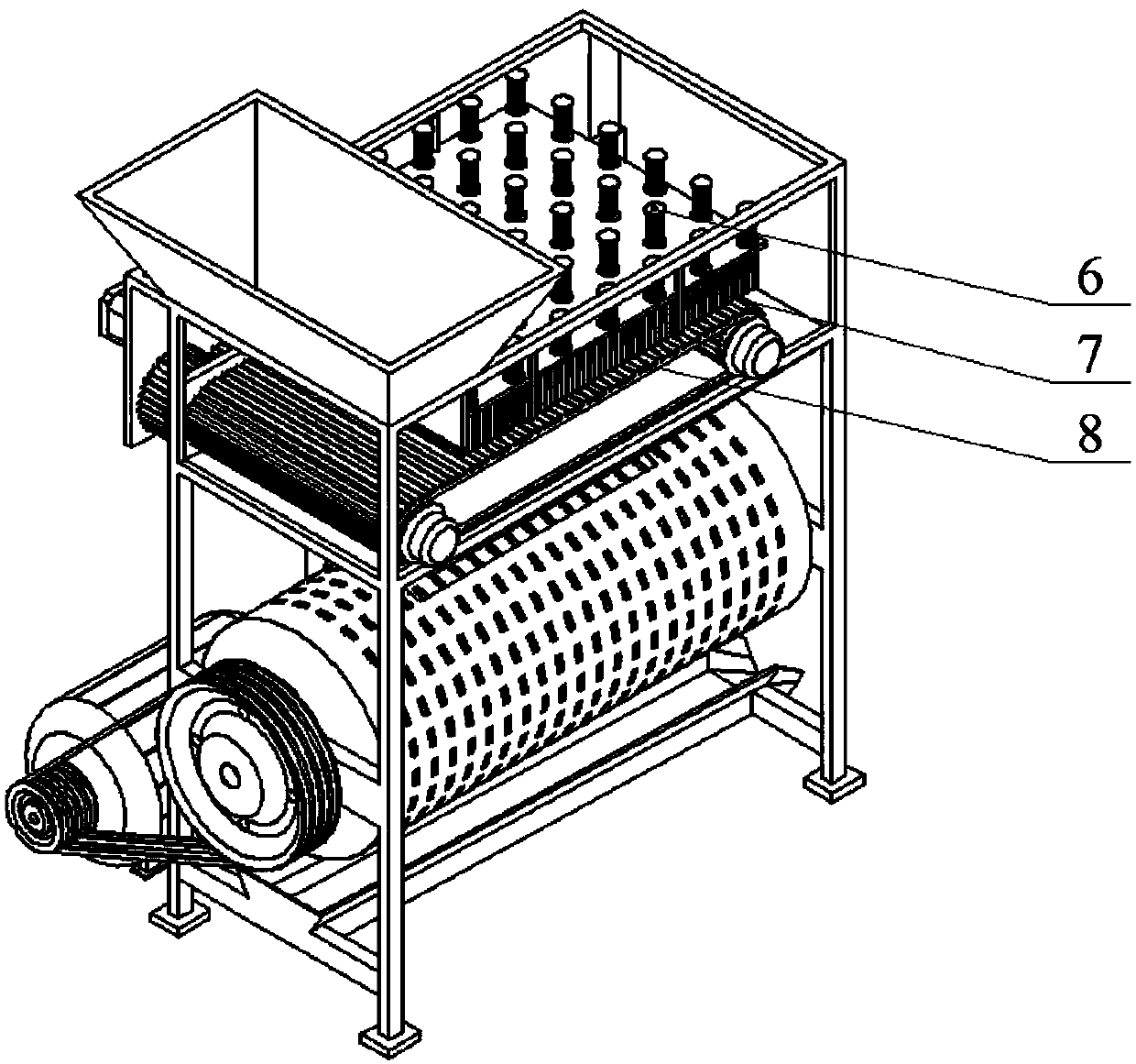

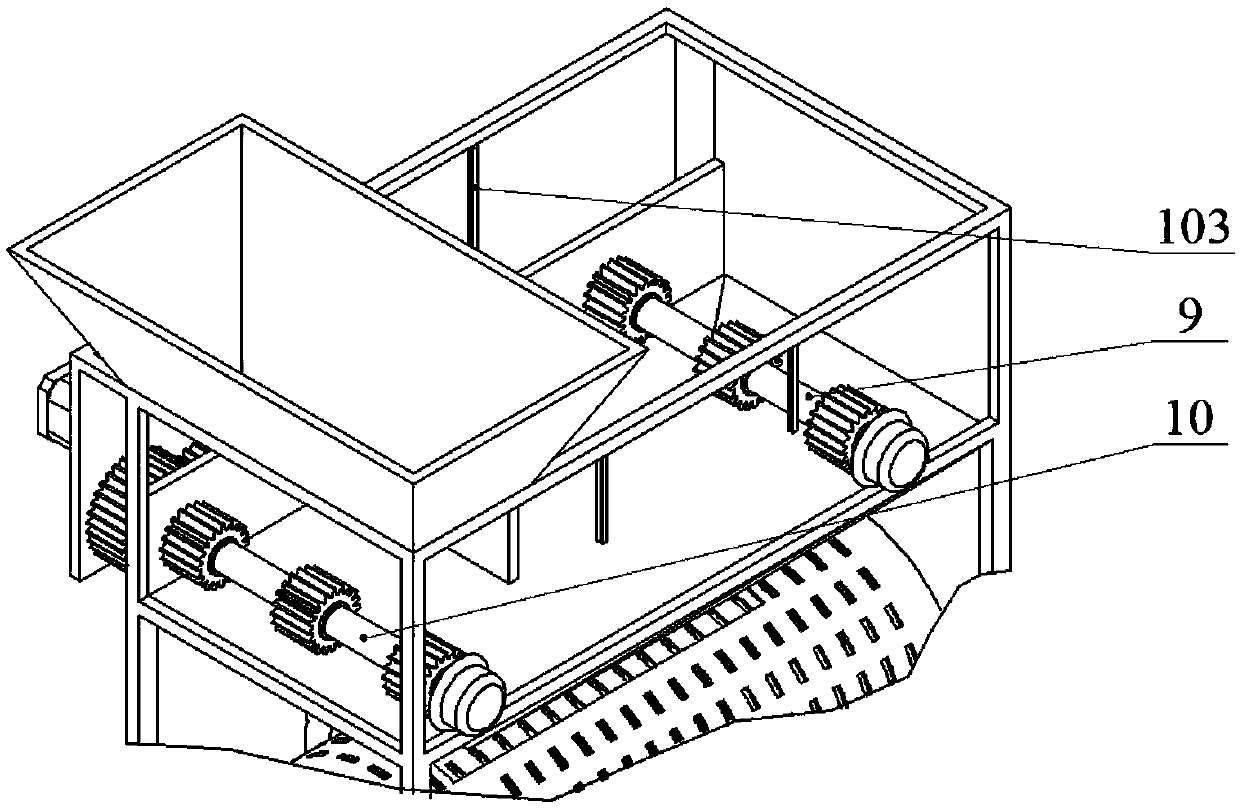

[0025] Combine below Figure 1-11 The structure of a kind of peanut shelling equipment invented is described in detail. Peanut shelling equipment is composed of an outer frame 1, a drum 2, a discharge chute 3, a blower 4 and a motor 5, and the outer frame 1 is provided with a feed port 101, a discharge port 102 and a slide rail 103. In the upper part of the outer frame 1, the thorn cone plate 7 is slidably installed on the inner side of the outer frame 1 through the slide rail 103, and springs 6 are installed at intervals above the thorn cone plate 7, and the spring 6 is fixed on the inside of the top plate of the outer frame 1, and the bottom of the thorn cone plate 7 is uniform The thorn cones 701 are distributed, and one side o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com