Positioning tool for clothing manufacturing workshop

A technology for manufacturing workshops and positioning tooling, applied in the field of clothing manufacturing, can solve the problems of easy wear and tear of fixed columns, high risk of sewing thread breakage, and constant sewing thread tension for a long time, so as to achieve the effect of stable rotation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

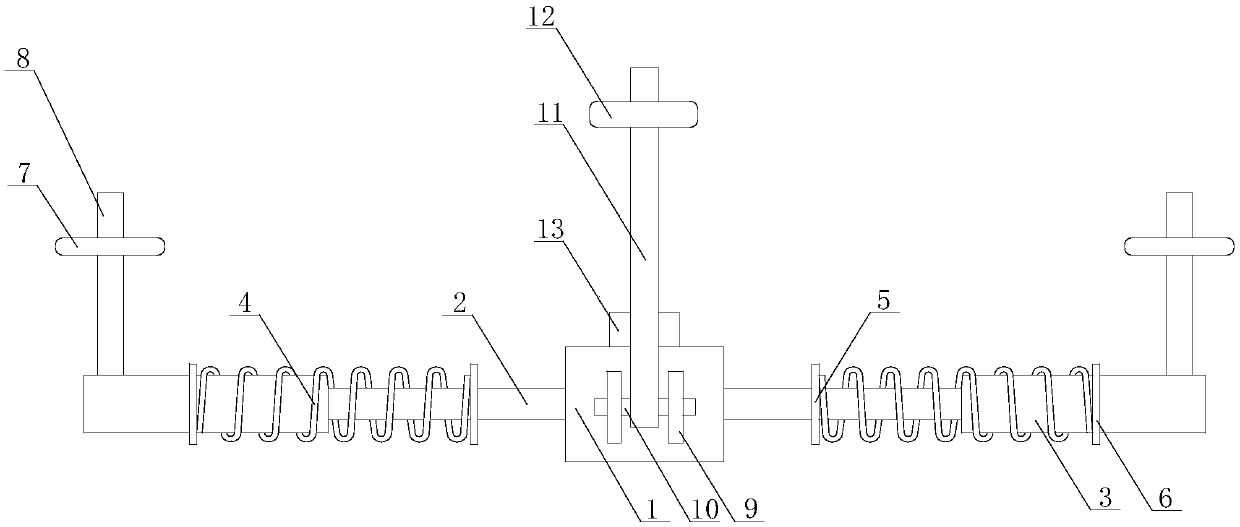

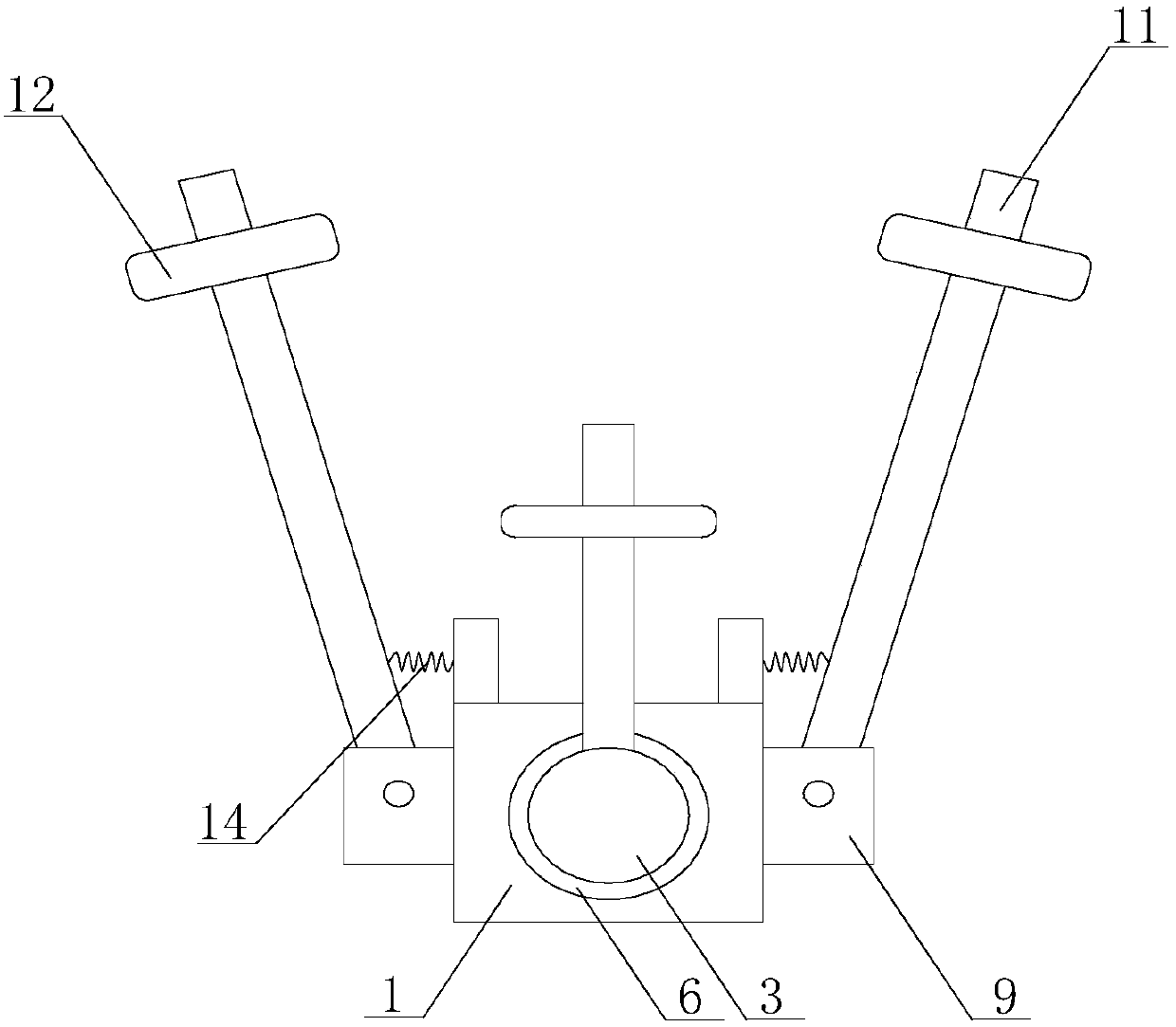

[0031] Such as figure 1 and figure 2 The shown positioning tool for a clothing manufacturing workshop includes a main collar 1, and two elastic telescopic mechanisms are fixedly connected to the side of the main collar 1, and the two elastic telescopic mechanisms are symmetrical about the main collar 1; It includes a first connecting rod 2 and a second connecting rod 3, one end of the first connecting rod 2 is fixed on the main collar 1, and the other end moves through an end face of the second connecting rod 3; the outer wall of the first connecting rod 2 is provided with a second A support plate 5, a second support plate 6 is arranged on the outer wall of the second connecting rod 3, and a spring 4 is arranged between the first support plate 5 and the second support plate 6; Auxiliary stabilizing mechanism, the two auxiliary stabilizing mechanisms are symmetrical about the main collar 1, and the connection line of the two auxiliary stabilizing mechanisms is perpendicular t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com