Lubricating oil containing surface-modified carbon nanomaterials and preparation method thereof

A carbon nanomaterial and surface modification technology, applied in lubricating compositions, petroleum industry, additives, etc., can solve the problem that the porous structure of the interface protective film cannot be maintained, the linear carbon nanotubes are easily entangled into clusters, and the graphene surface is inert. and other problems, to achieve the effect of improving bifunctional lubrication, improving mutual solubility and solving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] Step 1: Preparation of modified graphene nanomaterials

[0071] According to the mass ratio of 6:1-2:1, the number of layers is 1-10 layers, and the graphene and dopamine hydrochloride with a sheet size of 20-1000nm are added to a concentration of 0.01-0.10mol / L Tris. In the aqueous solution, the volume ratio of the aqueous solution of Tris to dopamine hydrochloride mass ratio is 3-5L / g; Adjust the pH value of the solution to be 8-9, ultrasonic shearing is processed until dopamine hydrochloride is completely dissolved, and graphene is fully dispersed; Add hydrogen peroxide according to the ratio of 30-50mL5% hydrogen peroxide per gram of dopamine, stir at 20-40°C for 1-10h, filter, wash and dry to obtain graphene nanomaterial A1 coated with polydopamine;

[0072]Add A1 and alkylamine to the ethanol solution of trishydroxymethylaminomethane with a concentration of 0.01-0.10mol / L according to the mass ratio of 1:4, and the solvent in the ethanol solution has a mass conc...

Embodiment 2

[0083] This embodiment is basically the same as Embodiment 1, the difference is:

[0084] The graphene layer number described in step 1 is 1-10 layers, sheet size 20-1000nm, most preferably 1-3 layers, sheet size 50-150nm; Described graphene and dopamine hydrochloride mass ratio are 6:1-2 : 1, the preferred mass ratio is 5: 1; the 20-40 ° C stirring 1-10h, preferably 1-2h;

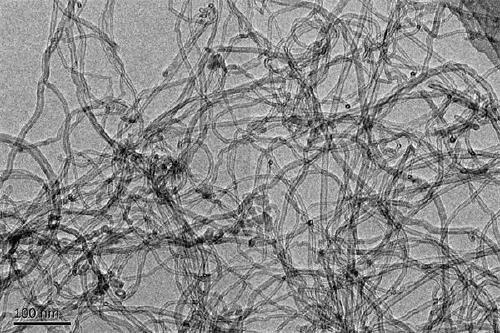

[0085] Step 2: The carbon nanotubes are multi-walled carbon nanotubes with a purity greater than 95%, a diameter of 8-30nm, and a length of 0.5-15μm; the most preferred purity is greater than 99.5%, 10-20nm, and a length of 0.5-5μm; the carbon The mass ratio of nanotubes to dopamine hydrochloride is 6:1-2:1, preferably 5:1; stirring at 20-40°C for 1-10h, preferably 1-2h;

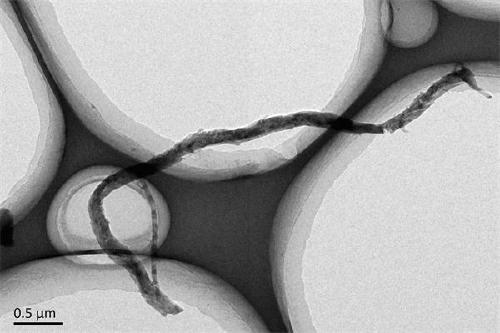

[0086] Step 3: The carbon nanofiber has a diameter of 50-200nm and a length of 1-20μm, most preferably a diameter of 50-100nm and a length of 5-10μm; the mass ratio of the carbon nanofiber to dopamine hydrochloride is 6:1-2:1, prefera...

Embodiment 3

[0094] The present embodiment is basically the same as Example 1, except that in step 1, the number of layers is 1-6 layers, and the graphene and dopamine hydrochloride of sheet size 100-200nm are added to the ratio of 2:1 according to the mass ratio. Concentration is in the aqueous solution of 0.01mol / L tris, the volume of the aqueous solution of tris and the dopamine hydrochloride mass ratio are 4L / g; At 8000 rpm, emulsify for 2 minutes, and then ultrasonically treat at a frequency of 20KHz until dopamine hydrochloride is completely dissolved and graphene is fully dispersed; add hydrogen peroxide at a rate of 40mL of 5% hydrogen peroxide per gram of dopamine hydrochloride, and react at 20-40°C 1-2h.

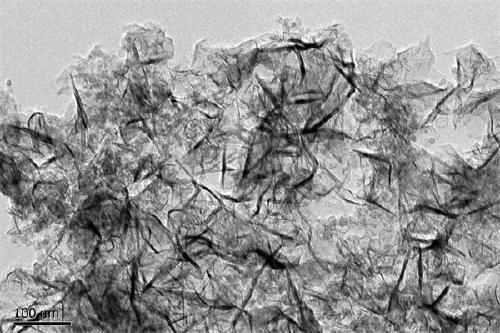

[0095] figure 1 It is the transparent radio microscope photograph of the graphene after embodiment 3 step 1 surface treatment. like figure 1 As shown, the graphene sheet size is about 100-200, and the thickness of the modified material increases, indicating that the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com