conductor connection device

A conductor connection and conductor technology, which is applied in the field of conductor connection devices, can solve the problems of reduced yield, difficulty in plating, high conductor cost, etc., and achieve the effect of preventing re-formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

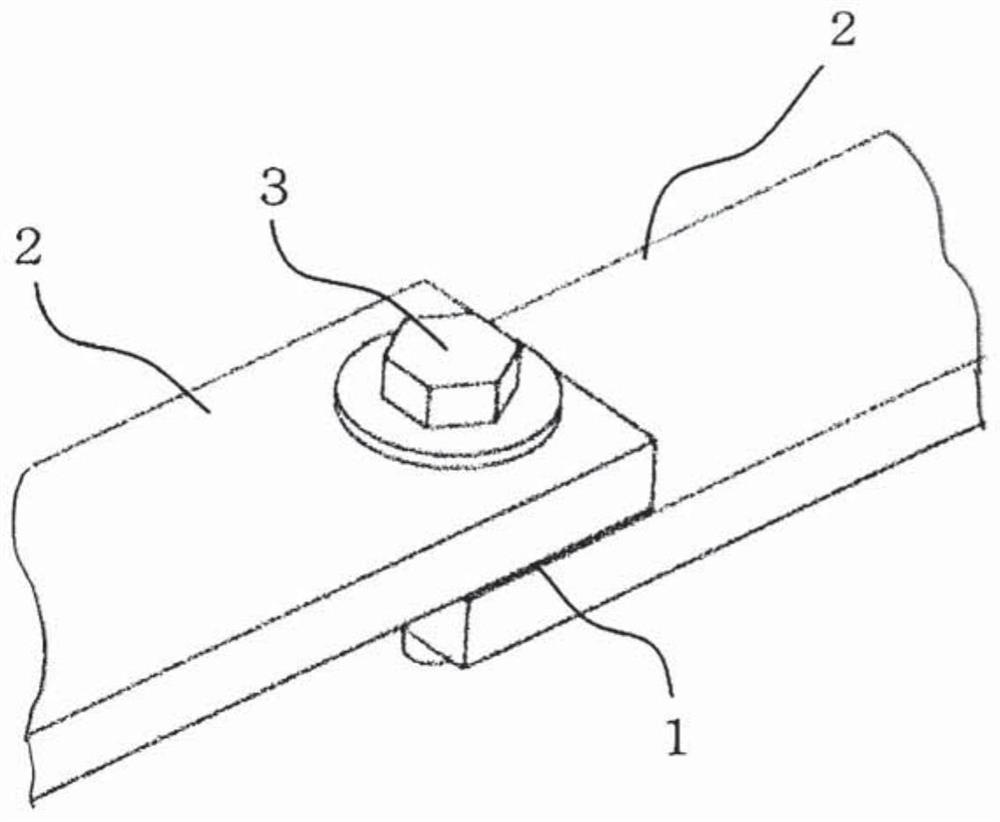

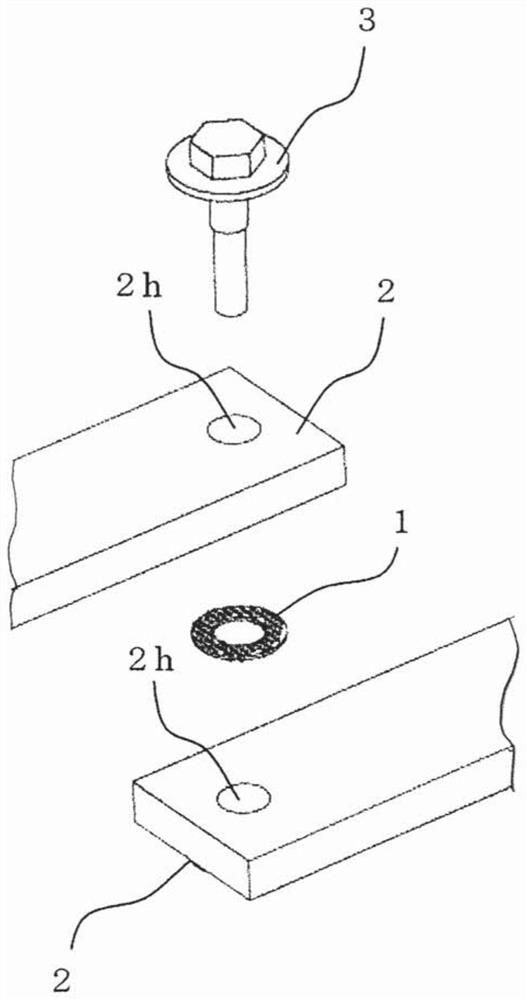

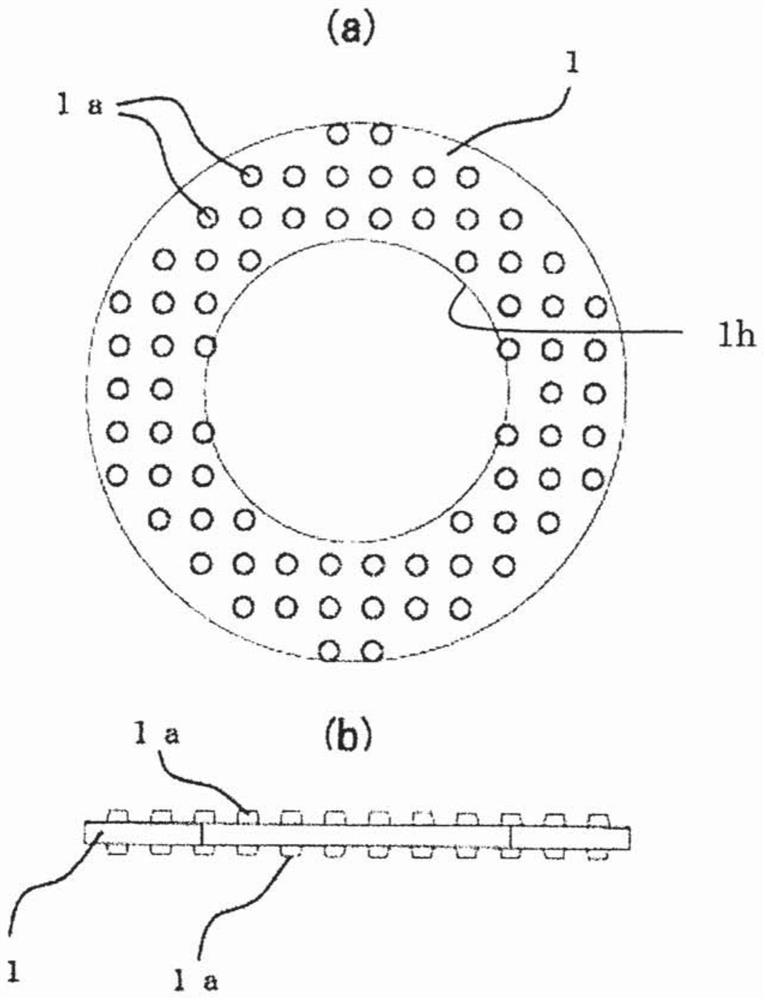

[0038] based on Figure 1 to Figure 4 The conductor connection device in Embodiment 1 will be described.

[0039] figure 1 is a perspective view of the conductor connection device, figure 2 is an exploded perspective view of the conductor connection device, image 3 (a) is a front view of a conductive member for conductor connection, image 3 (b) is a side view, Figure 4 It is an explanatory diagram showing the test results of a short-time energization test conducted to confirm the performance of the conductive member for conductor connection.

[0040] The conductor connecting device is composed of a fastener (fastening member) and a conductive member for connecting flat conductors (hereinafter referred to as “conductive member with protrusions” as appropriate) 1. Bolts 3 and nuts (not shown), the conductive member for connecting the flat conductors is inserted (sandwiched) between the two conductors when the conductors 2 are connected and fastened. Similar to the washe...

Embodiment approach 2

[0049] based on Figure 5 to Figure 7 A conductor connection device in Embodiment 2 will be described.

[0050] Figure 5 is a perspective view of the conductor connection device, Figure 6 is an exploded perspective view of the conductor connection device, Figure 7 (a) is a front view of the conductive member, Figure 7 (b) is a side view.

[0051] In Embodiment 1, a protruding conductive member 1 having a shape similar to a washer is used, but as Figure 5 As shown, in the case of fastening conductors 2 to each other with a plurality of bolts 3 , it is necessary to insert protruding conductive members 1 having a shape similar to washers according to the number of holes in the fastening portion. In contrast, in Embodiment 2, using Figure 7 Such abutting plate-shaped conductive member 4 with protrusions. Thus, if Figure 6 As shown, even if a plurality of fastening holes are opened on the conductor 2, only one conductive member 4 with a protrusion needs to be clamped...

Embodiment approach 3

[0053] based on Figure 8 to Figure 9 A conductor connection device in Embodiment 3 will be described.

[0054] Figure 8 is a perspective view of the conductor connection device, Figure 9 (a) is a front view of the conductor member, Figure 9 (b) is a side view.

[0055] In Embodiments 1 and 2, the conductors 2 are overlapped and connected. In Embodiment 3, the conductors 2 are connected to each other, and the conductors 2 are connected to each other through the abutting plate-shaped conductive member 5 with protrusions. In the case of the above-mentioned conductor connection, the conductive member 5 for connecting the conductor 2 is connected to the surface of the conductor 2 in the same direction, so that the protrusion 5a of the conductive member 5 abutting on the plate-shaped band protrusion is only implemented on one side. Formation and coating of a conductive auxiliary coating agent are sufficient. therefore, Figure 9 The surface of the shown abutting plate-shap...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com