Coulomb-force-traction spherical compression jet airflow arc-extinguishing device and sphere type arcing horn

A technology of jet air flow and arc extinguishing device, which is applied to corona discharge devices, electrical components, insulators, etc., can solve the problem of not being able to ensure the safe operation of metal transmission lines, and achieve safe and stable operation, good lightning protection and arc extinguishing. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

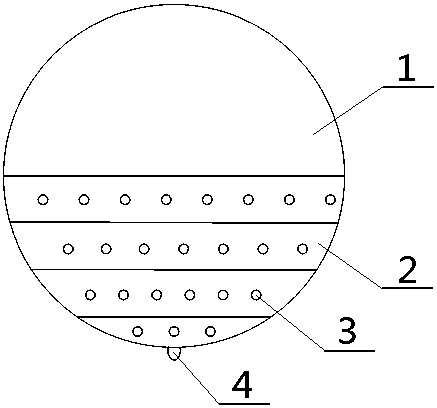

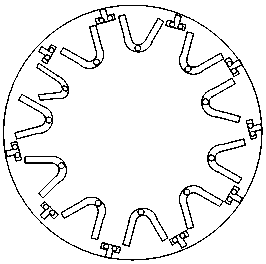

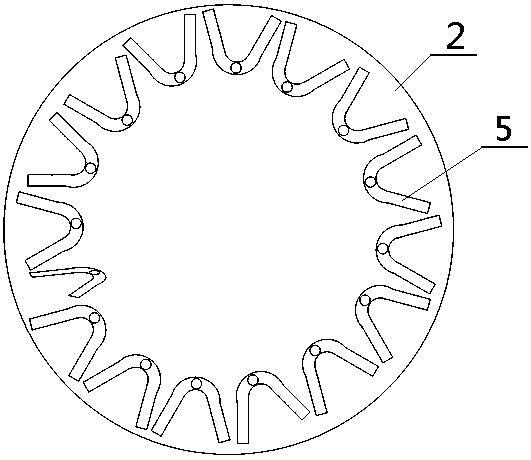

[0043] Such as Figure 1-4 As shown, a spherical compressed jet air arc extinguishing device pulled by Coulomb force is mainly composed of upper and lower hemispheres, wherein the upper hemisphere is a metal hemisphere 1 for Coulomb force arc ignition, and the lower hemisphere is an insulating compressed arc extinguishing hemisphere 2; The insulating compression arc extinguishing hemisphere 2 is provided with several layers of arc extinguishing channels arranged along the circumference, and several arc extinguishing tubes are placed in each layer of arc extinguishing channels, and the last arc extinguishing channel in the upper layer of arc extinguishing channels The tube is electrically connected to the first arc extinguishing tube in the arc extinguishing channel of the next layer, and the ends of two adjacent arc extinguishing tubes in the same layer of arc extinguishing channel are connected through the connecting piece 6; The joints of two adjacent arc extinguishing tubes...

Embodiment 2

[0047] The difference between this embodiment and embodiment 1 is: as Figure 7 , Figure 8 As shown, the arc extinguishing tube adopts an in-line arc extinguishing tube; and the ends of two adjacent in-line arc extinguishing tubes away from the outer surface of the insulating compression arc extinguishing hemisphere are connected together through the arc connecting electrodes; The two ends of the arc-guiding connection electrode are respectively embedded in the in-line arc extinguishing tube. The inside of the in-line arc extinguishing tube is provided with an arc guiding ball and two compression cold wall tubes; the arc guiding ball is placed between the two compression cold wall tubes, There is also an arc guide ring at the port.

Embodiment 3

[0049] The difference between this embodiment and embodiment 1 is: as Image 6 As shown, the outer surface of the insulating compression arc extinguishing hemisphere 2 is also provided with a skirt 10, and the skirt 10 is arranged along the direction in which the airflow outlets 3 are arranged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com