Rotating obstacle clearing drill bit

A drill bit and obstacle removal technology, which is applied in the direction of pipes/pipe joints/fittings, special pipes, mechanical equipment, etc. It can solve the problems of difficult to clean blockages and waste blockages in drainage pipes, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

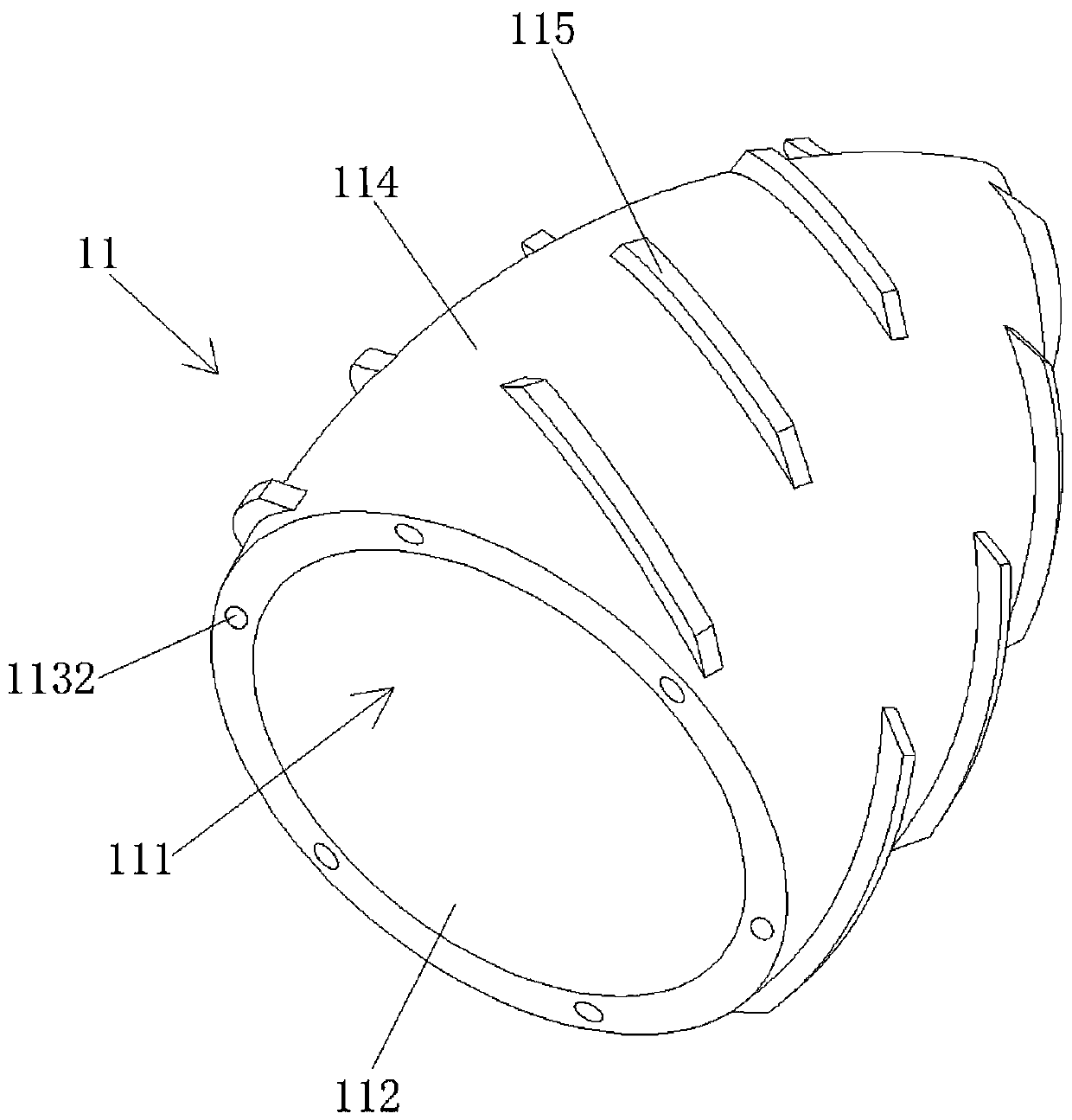

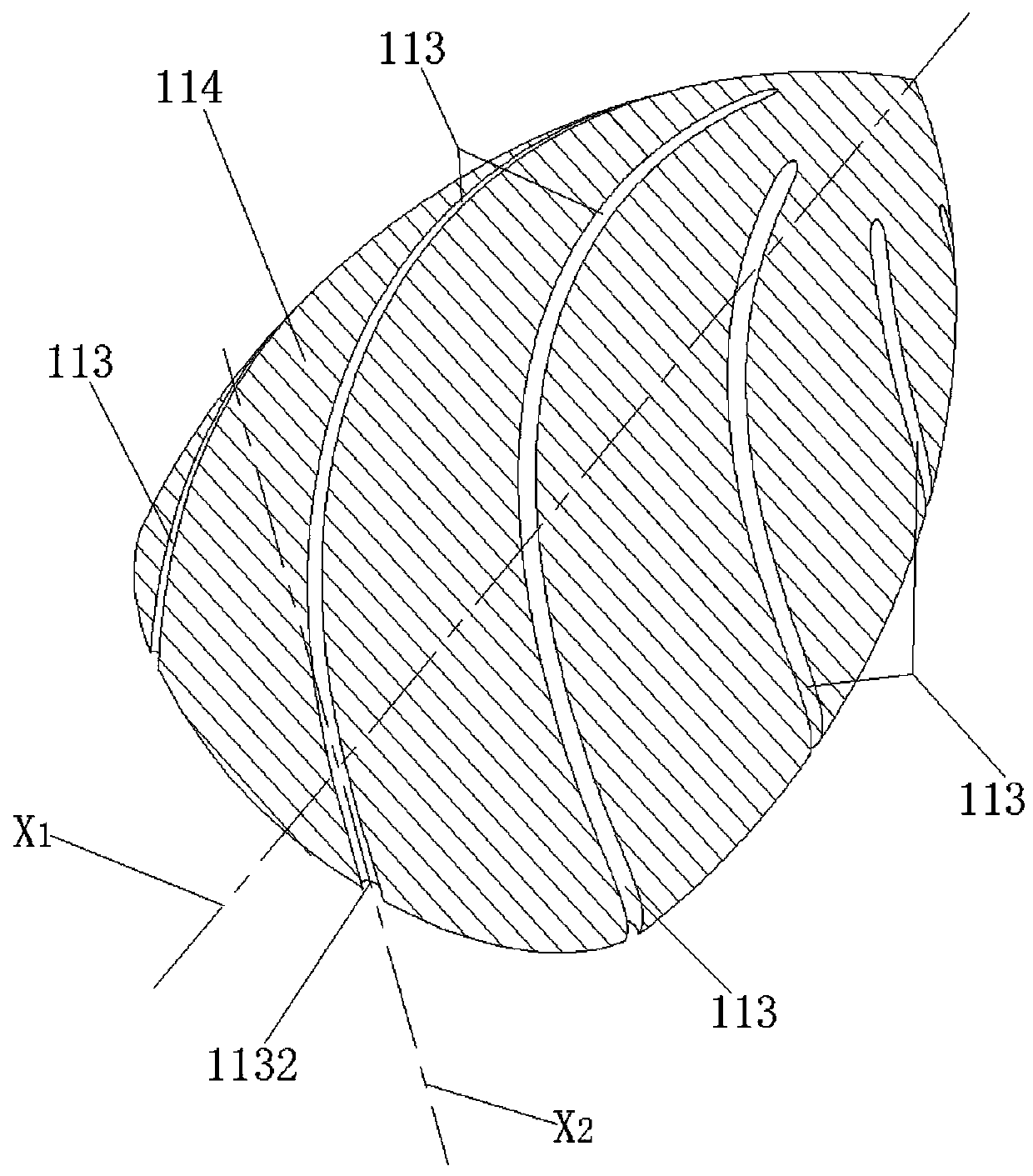

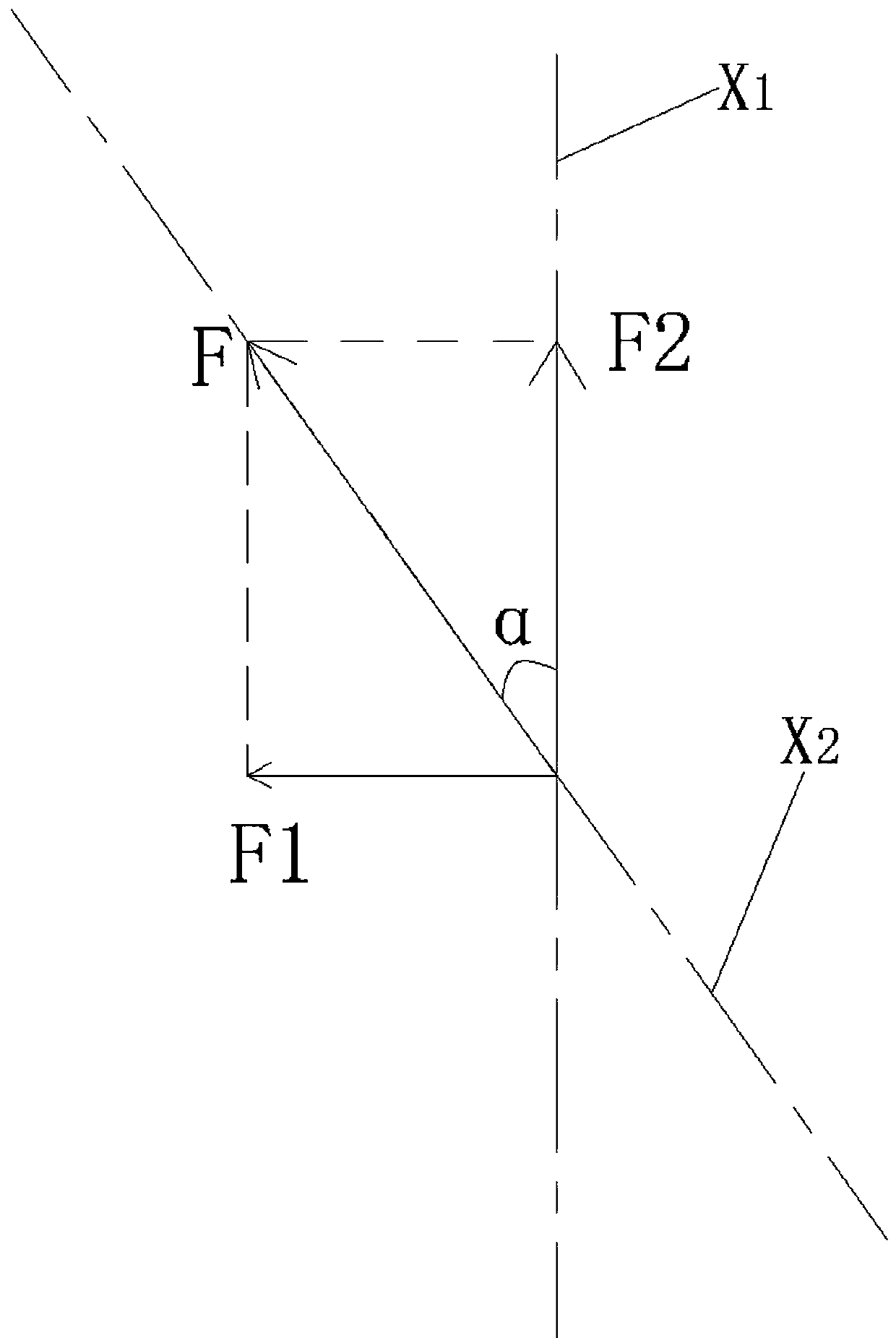

[0035] Please also refer to Figure 1 to Figure 7 , figure 1 It is a perspective view of Embodiment 1 of the rotary obstacle-clearing drill bit of the present invention, figure 2 for figure 1 Schematic diagram of the spiral channel in the cavity wall of the middle bit body, image 3 for figure 1 Schematic diagram of the reaction force of the high-pressure water sprayed from the spiral channel of the middle rotary obstacle-clearing drill bit on the rotary obstacle-clearing drill bit, Figure 4 for figure 1 Rear view of the Rotary Wrecker Bit in the middle, Figure 5 for figure 1 Side view of the Rotary Wrecker Bit in the middle, Image 6 for figure 1 Front view of the Rotary Wrecker Bit in the middle, Figure 7 for figure 1 Schematic diagram of the structure of the blade of the rotary obstacle-clearing drill bit.

[0036] The rotary obstacle removal drill bit of the present invention includes a drill body 11. A high-pressure water containing cavity 111 is arranged i...

Embodiment 2

[0051] Please also refer to Figure 8 to Figure 10 , Figure 8 It is a perspective view of Embodiment 2 of the rotary obstacle-clearing drill bit of the present invention, Figure 9 for Figure 8 Rear view of the Rotary Wrecker Bit in the middle, Figure 10 for Figure 8 A cross-sectional view of the connection between the middle rotary obstacle removal drill bit and the joint at the front end of the high-pressure water pipe. The afterbody of drill body 21 is provided with the water pipe joint 22 that is used for freely rotating sealing connection with the high-pressure water pipe of the pipeline wrecker. A water injection port for injecting high-pressure water in the body 211. The rotary wrecker drill bit will also be able to rotate freely while being sealed with the high-pressure water pipe of the pipeline wrecker. The water pipe joint 22 is set to make the connection more convenient. The high-pressure water pipe of the water pipe joint 22 and the pipeline wrecker can b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com