Hard sealing plane elastic gate plate pair

A hard seal and sealing surface technology, applied in sliding valves, engine components, mechanical equipment, etc., can solve problems such as imperfect product performance, risk of storage and transportation of hazardous chemicals, and delays in work, and expand the application of high temperature and high pressure resistance demand, avoid valve internal leakage and stuck accidents, and expand the effect of application fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

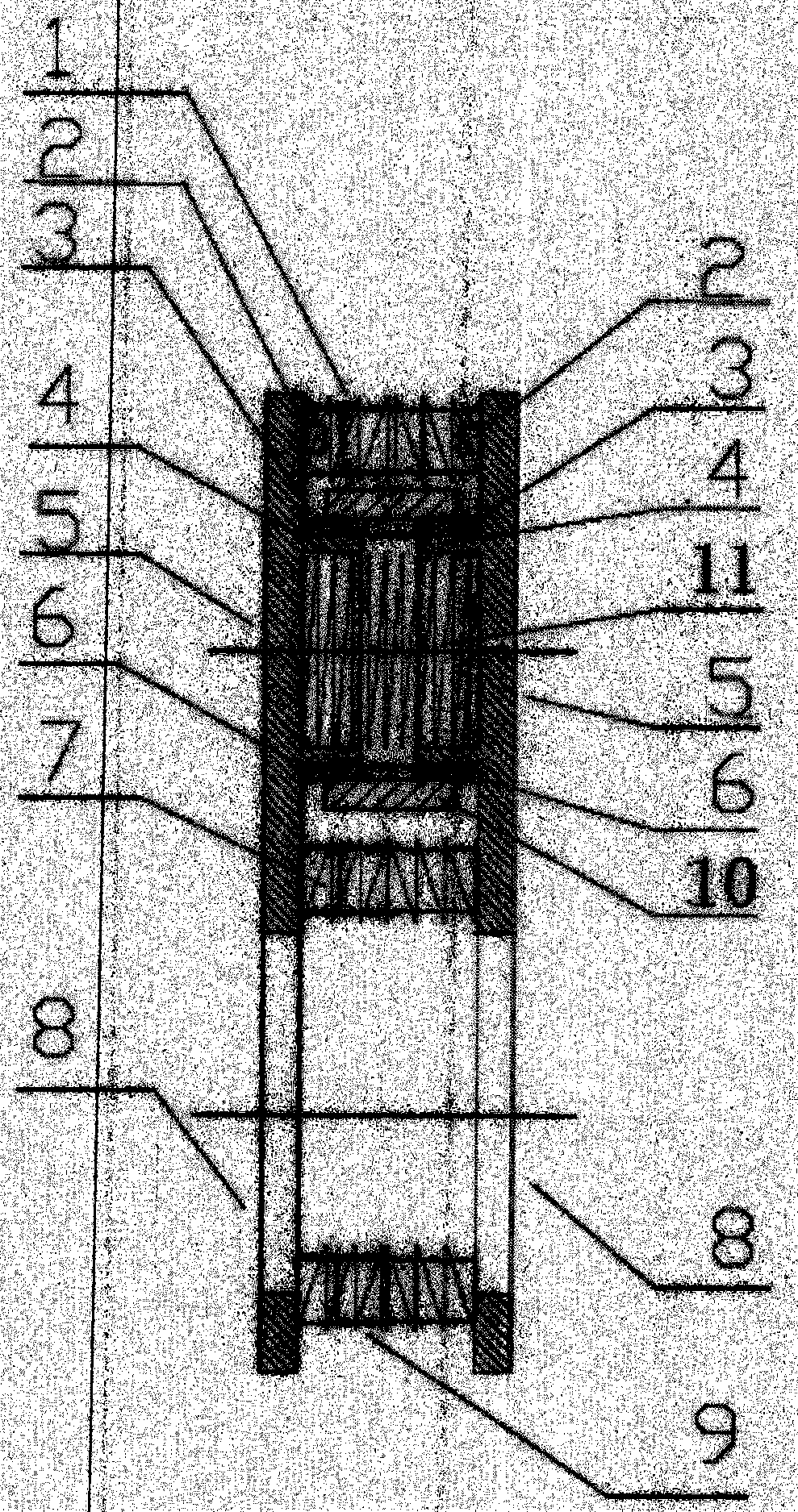

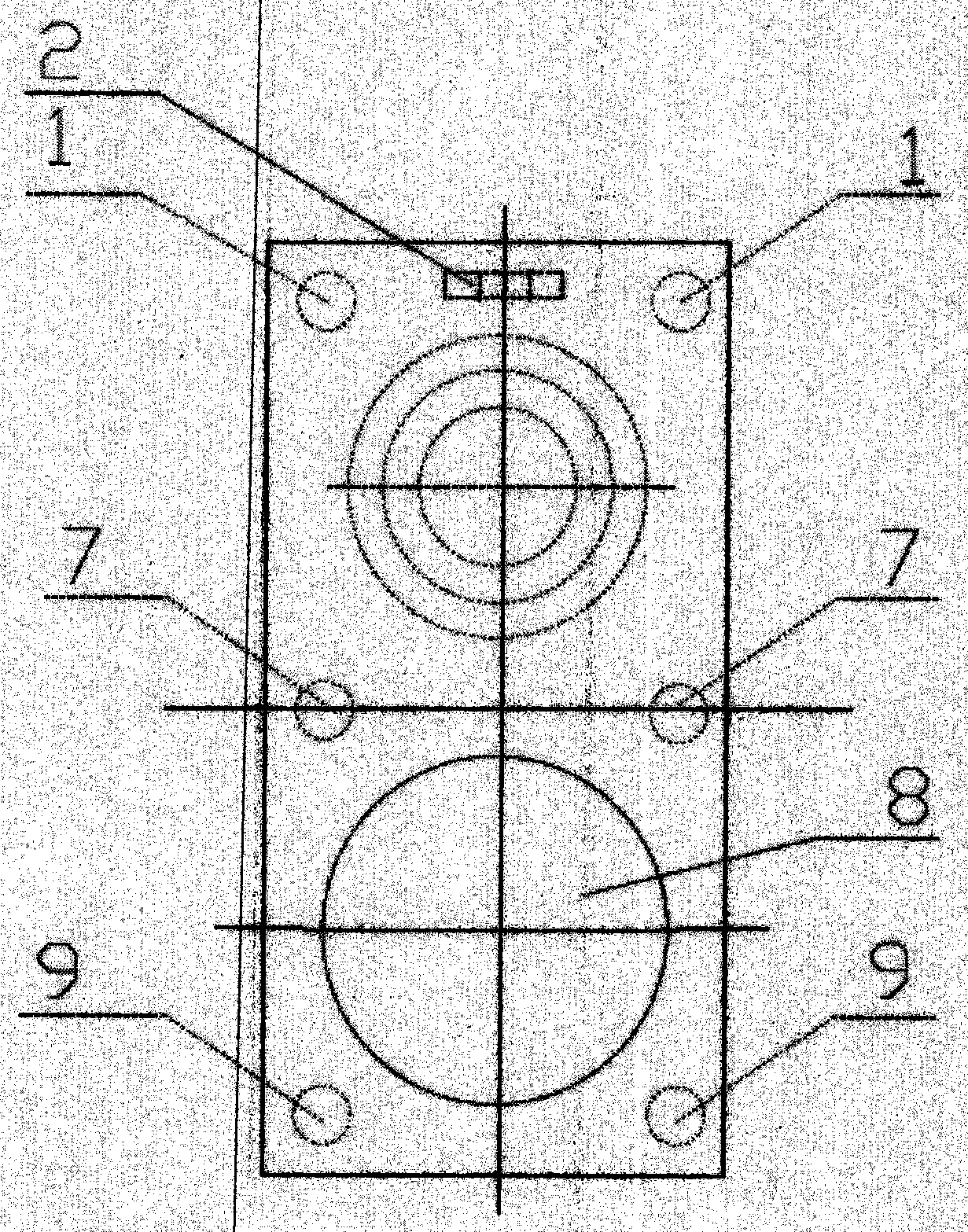

[0023] image 3 The fully open state of the present invention in practical application is shown.

[0024] refer to image 3 , the hard-sealed planar elastic gate pair of the present invention is assembled with the housing of the planar gate valve, and after the working position is assembled in place, the special tool for temporarily locking the gate tension seat 2 is removed, and the hollow core of the present invention is positioned The spring 11 in the shaft 4 expands to both sides, so that the gap between the sealing surface of the two gates 5 and the sealing surface of the annular sealing seat 16 in the outer plane gate valve housing is immediately eliminated and pressed together to maintain a stable thickness. This prevents the effective sealing surface from being impacted by the fluid medium when the medium flows through the medium channel 15 of the valve, thereby improving the service life of the planar gate valve.

Embodiment 2

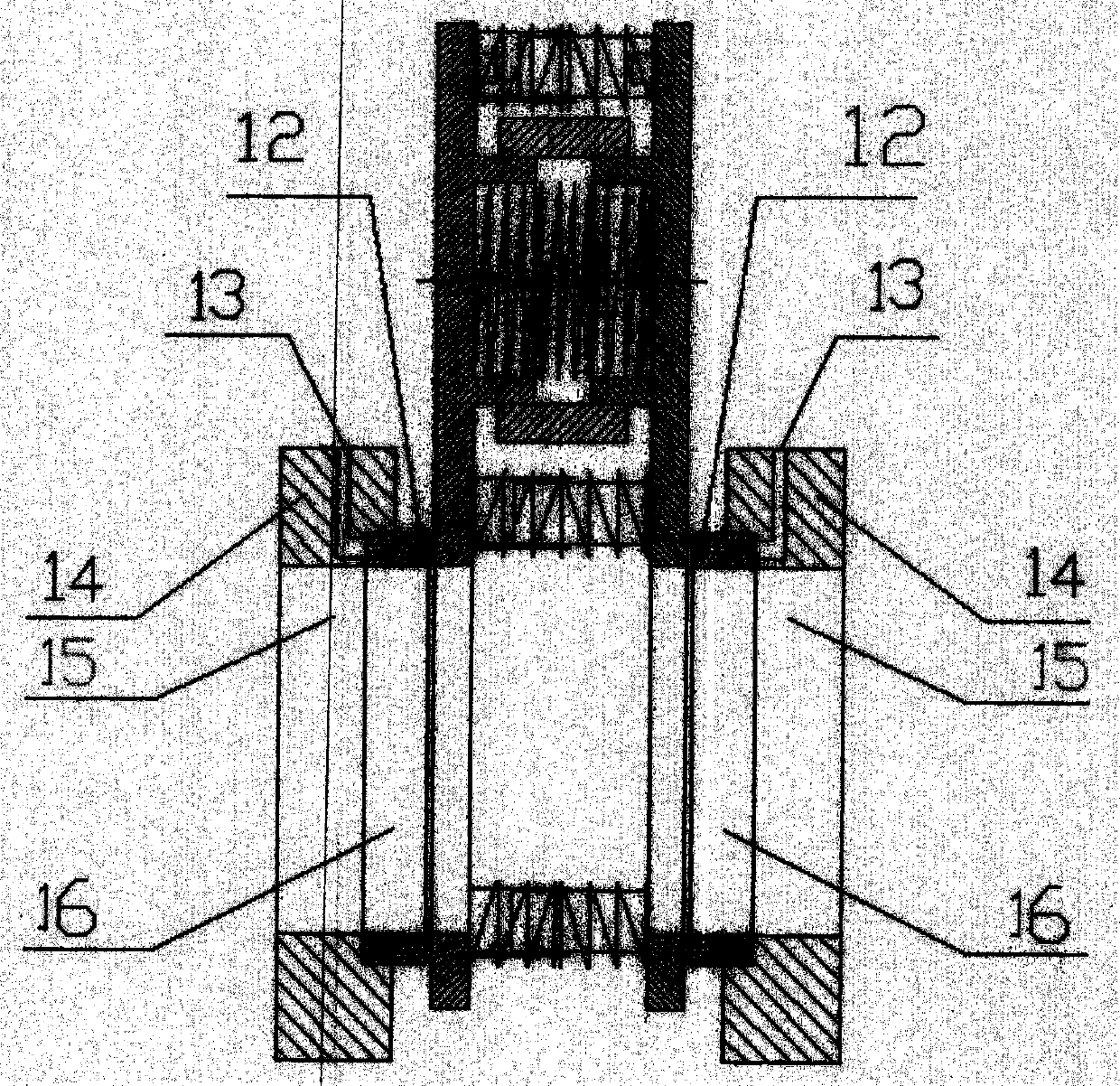

[0026] Figure 4 It shows the fully closed state of the present invention in practical application.

[0027] refer to Figure 4 and combine image 3 , after the hard-sealed planar elastic gate pair of the present invention is connected with the valve screw rod, it is assembled together with the shell of the planar gate valve as shown in FIG. image 3 In the fully open state, the screw rod is welded to the positioning seat sleeve 10 of the present invention, so that the present invention is pushed down to the valve medium channel through the positioning seat sleeve 10 driven by external torque 15 vertical displacement as Figure 4 The channel is shown fully closed.

[0028] exist Figure 4 In the fully closed state shown, there are two cases of positive sealing pressure on the sealing surface:

[0029] One situation is that the pressure of the medium does not exceed the sum of the elastic forces of all the springs inside the invention. At this time, the pressing overlap b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com