A kind of ZN-NB-TI system LTCC material and preparation method thereof

A zn-nb-ti, base material technology, applied in the field of electronic ceramics and its manufacturing, can solve the problem of high sintering temperature and inability to apply LTCC process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

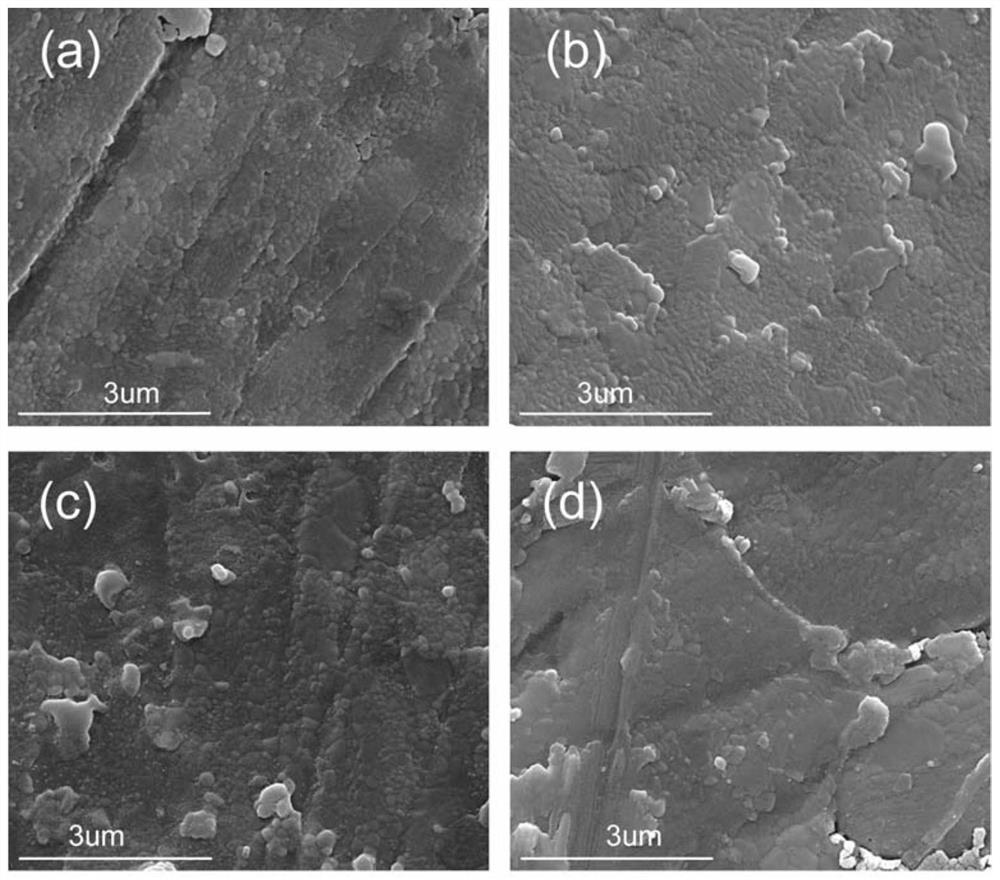

[0016] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

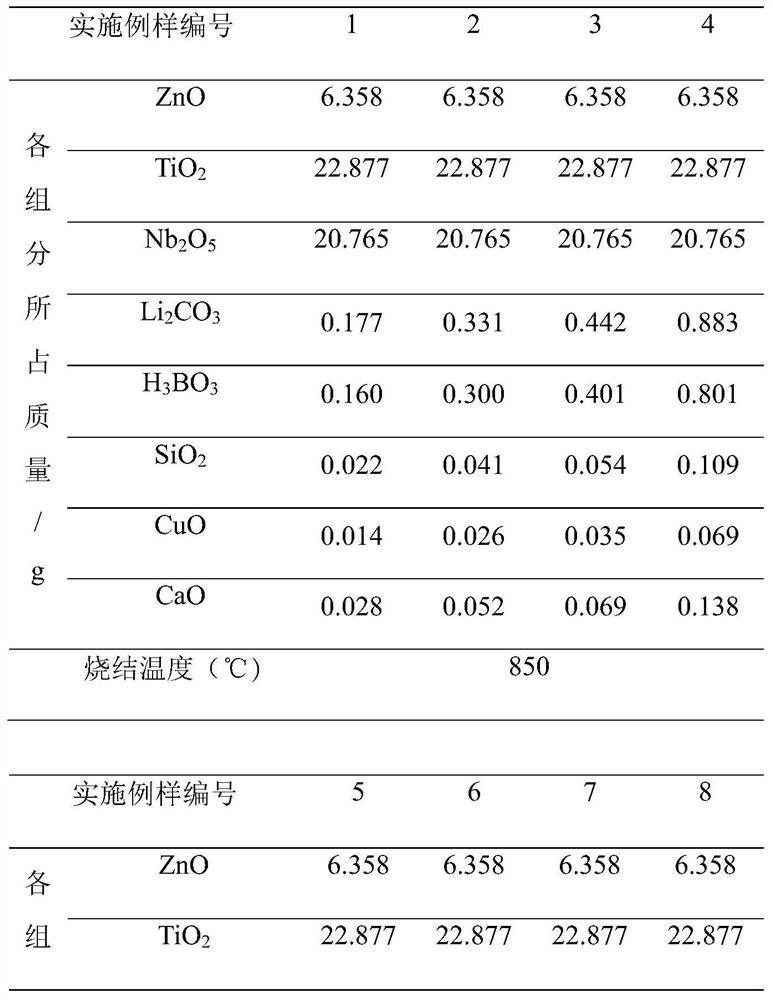

[0017] Step 1: Prepare the main crystal phase calcined material, ZnO, TiO 2 , Nb 2 o 5 The analytically pure raw powder according to Zn 0.15 Nb 0.3 Ti 0.55 o 2 Chemical formula for batching; mix the prepared powder according to the mass ratio of powder: zirconium ball: deionized water = 1:5:2, planetary ball milling for 6 hours, drying and sieving (60 mesh) after ball milling, and then at 950 ° C The main crystal phase (Zn 0.15 Nb 0.3 Ti 0.55 o 2 Phase), that is, pre-fired powder;

[0018] Step 2: Prepare a fever reducer, and Li 2 CO 3 、H 3 BO 3 , SiO 2 , CuO and CaO ingredients, ball milled for 7 hours, then dried through a 60-mesh sieve, then pre-fired at 600°C for 3 hours, and finally kept at 1350°C for 1.5 hours to melt the glass slag, and the prepared glass slag was crushed and ball-milled into powder for later use;

[001...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com