A high-performance permeable brick

A permeable brick, high-performance technology, applied in the field of building materials, can solve the problems of easy collapse of microporous structure, reduce the density of permeable bricks, etc., achieve the effect of reducing density, improving strength and ensuring degradation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

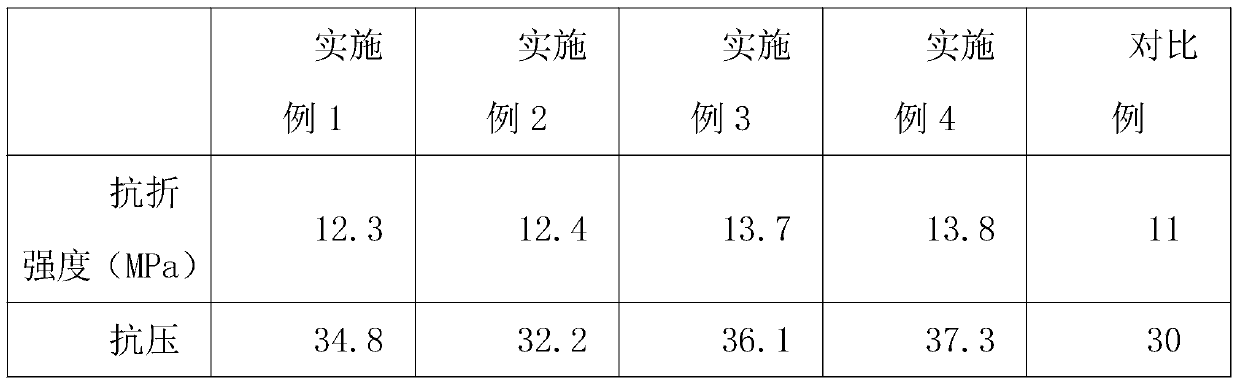

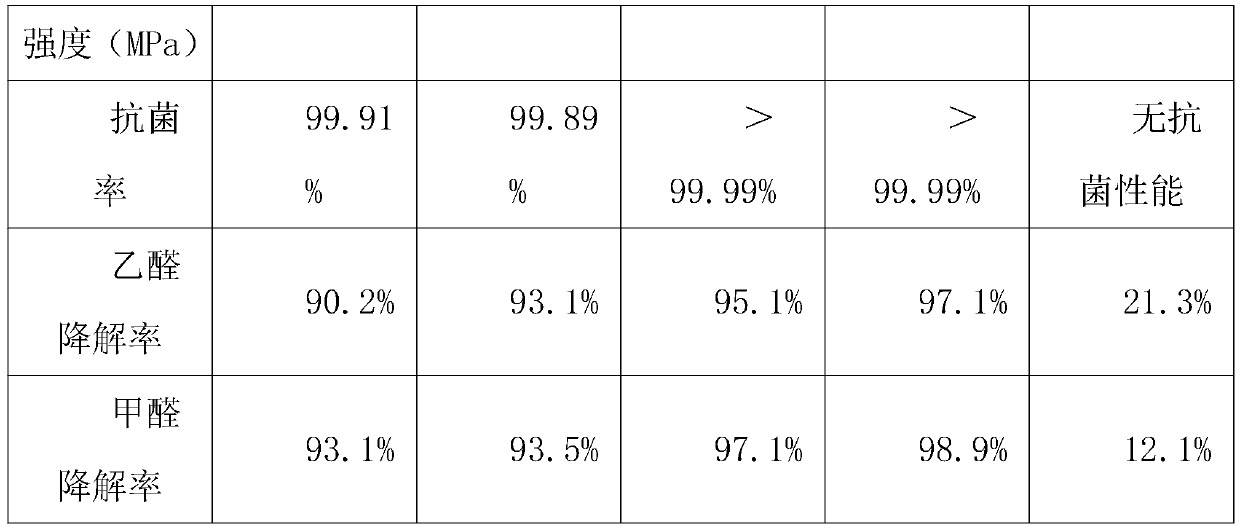

Examples

Embodiment 1

[0027] A high-performance permeable brick, its quality formula is as follows:

[0028] 10 parts of ceramic tile waste tile particles, 4 parts of titanium carbide, 10 parts of aluminum oxide, 10 parts of silicone resin, 13 parts of polyurethane resin, 7 parts of nano-titanium dioxide, 20 parts of absolute ethanol, and 3 parts of dispersant.

[0029] The dispersant adopts polyvinylpyrrolidone.

[0030] The preparation method of the high performance permeable brick, its steps are as follows:

[0031] Step 1, crushing the waste ceramic tile particles until fine particles are formed;

[0032] Step 2, mixing and stirring titanium carbide, powdered ceramic tile waste tile particles and alumina to obtain a powder mixture;

[0033] Step 3, adding the powder mixture to the silicone resin and polyurethane resin, stirring evenly, putting it into a mold, pressurizing and heating for 2 hours, and obtaining organic bricks after cooling;

[0034] Step 4, put the organic bricks into a seale...

Embodiment 2

[0043] A high-performance permeable brick, its quality formula is as follows:

[0044] 15 parts of ceramic tile waste tile particles, 8 parts of titanium carbide, 15 parts of aluminum oxide, 15 parts of silicone resin, 15 parts of polyurethane resin, 10 parts of nano-titanium dioxide, 30 parts of absolute ethanol, and 5 parts of dispersant.

[0045] The dispersant adopts polyvinylpyrrolidone.

[0046] The preparation method of the high performance permeable brick, its steps are as follows:

[0047] Step 1, crushing the waste ceramic tile particles until fine particles are formed;

[0048] Step 2, mixing and stirring titanium carbide, powdered ceramic tile waste tile particles and alumina to obtain a powder mixture;

[0049] Step 3, adding the powder mixture to the silicone resin and polyurethane resin, stirring evenly, putting it into a mold, pressurizing and heating for 4 hours, and obtaining organic bricks after cooling;

[0050] Step 4, put the organic bricks into a seal...

Embodiment 3

[0059] A high-performance permeable brick, its quality formula is as follows:

[0060]12 parts of ceramic tile waste tile particles, 6 parts of titanium carbide, 13 parts of aluminum oxide, 12 parts of silicone resin, 14 parts of polyurethane resin, 8 parts of nano-titanium dioxide, 25 parts of absolute ethanol, and 4 parts of dispersant.

[0061] The dispersant adopts polyvinylpyrrolidone.

[0062] The preparation method of the high performance permeable brick, its steps are as follows:

[0063] Step 1, crushing the waste ceramic tile particles until fine particles are formed;

[0064] Step 2, mixing and stirring titanium carbide, powdered ceramic tile waste tile particles and alumina to obtain a powder mixture;

[0065] Step 3, adding the powder mixture to the silicone resin and polyurethane resin, stirring evenly, putting it into a mold, pressurizing and heating for 3 hours, and obtaining organic bricks after cooling;

[0066] Step 4, put the organic bricks into a sealed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com