Driving gear of large type excavator for open-pit mine

A driving wheel, open-pit mine technology, applied in motor vehicles, earthmovers/shovels, crawler vehicles, etc., can solve the problems of reduced use costs, easy breakage, and increased product life, and achieve the effect of reducing comprehensive use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

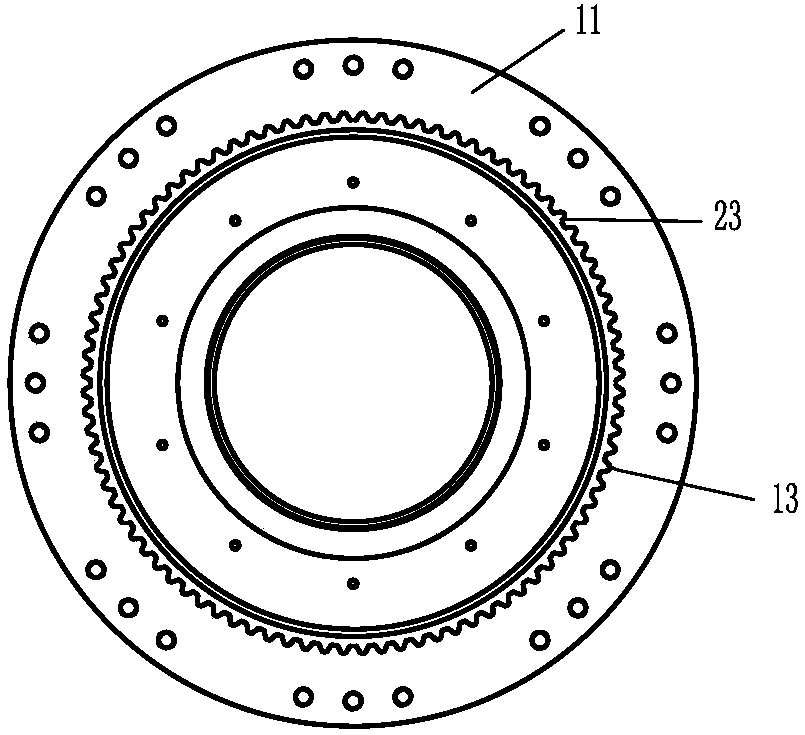

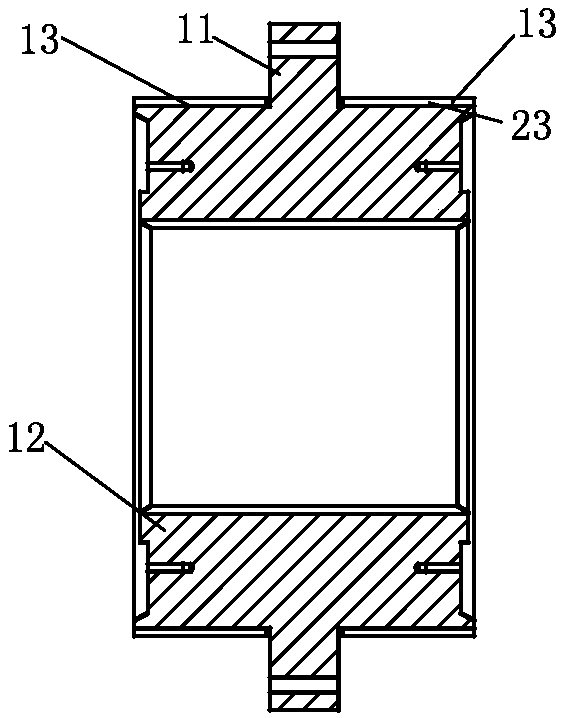

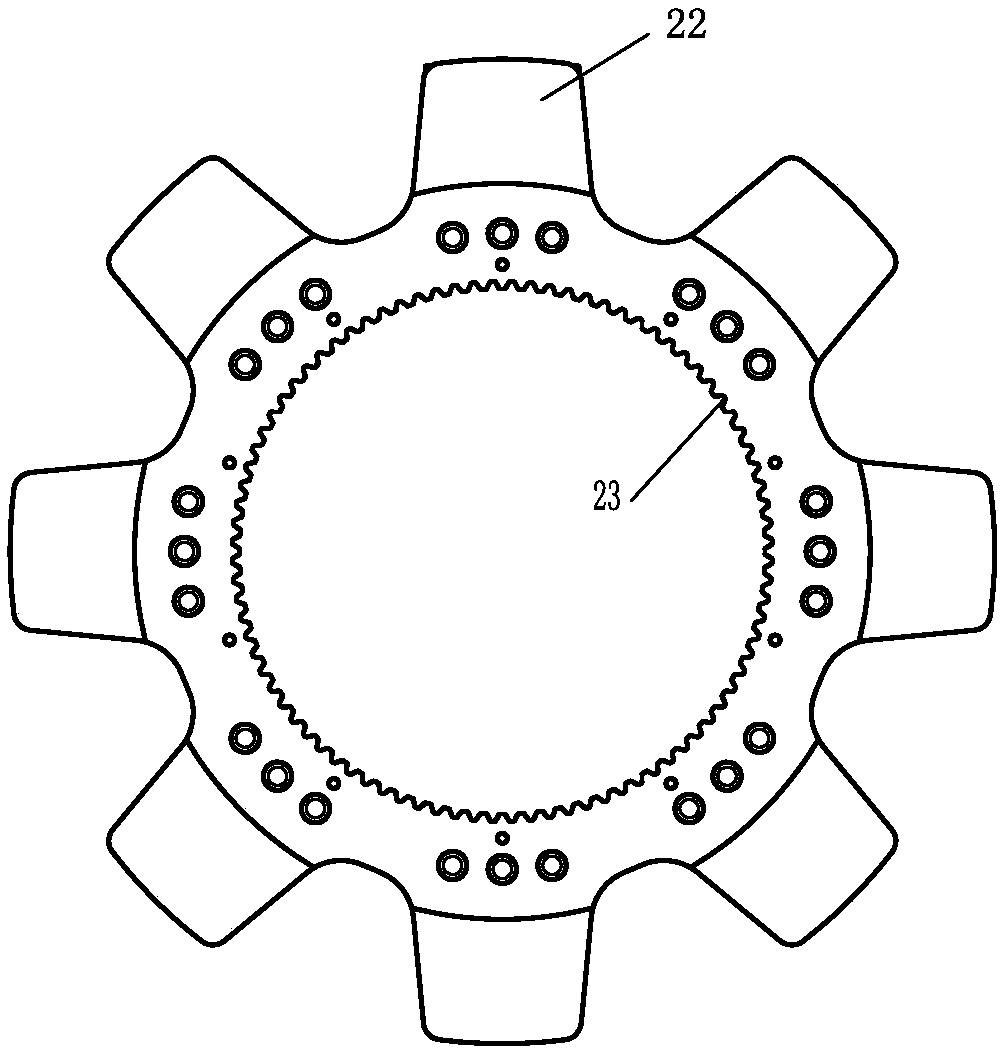

[0023] Such as Figure 5-6 As shown, a driving wheel for a large-scale excavator in an open-pit mine includes a wheel body 1 and a gear tooth 2, and the wheel body 1 and the gear teeth 2 are arranged separately; the wheel body 1 is arranged in a circle along the middle of the outer edge It is an integrally formed annular flange 11 of equal thickness; see Figure 1-4 The thickness of the annular flange 11 is less than the thickness of the wheel body 1 disc 12, so that the two sides of the bottom of the annular flange 11 form a symmetrical outwardly expanding annular shoulder 13; the gear teeth 2 are set to two A symmetrical ring gear ring 21, the ring gear ring 21 is evenly arranged with a plurality of gear teeth 22 along the circumference, the inner ring of the ring gear ring 21 is connected with the annular shoulder 13 of the wheel body 1 by a spline 23 , the ring gear ring 21 is symmetrically arranged on both sides of the ring flange 11, and the ring gear ring 21 is fixed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com