Belling bearing spacing adjustment device

A technology for adjusting device and spacing, applied in printing, rotary printing presses, printing presses, etc., it can solve the difference between the moving distance of the screw and the sliding block and the theory, reduce the adjustment accuracy, product yield rate, embossing depth effect changes, etc. problem, to achieve the effect of improving accuracy and product yield, low friction, fast and stable spacing adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

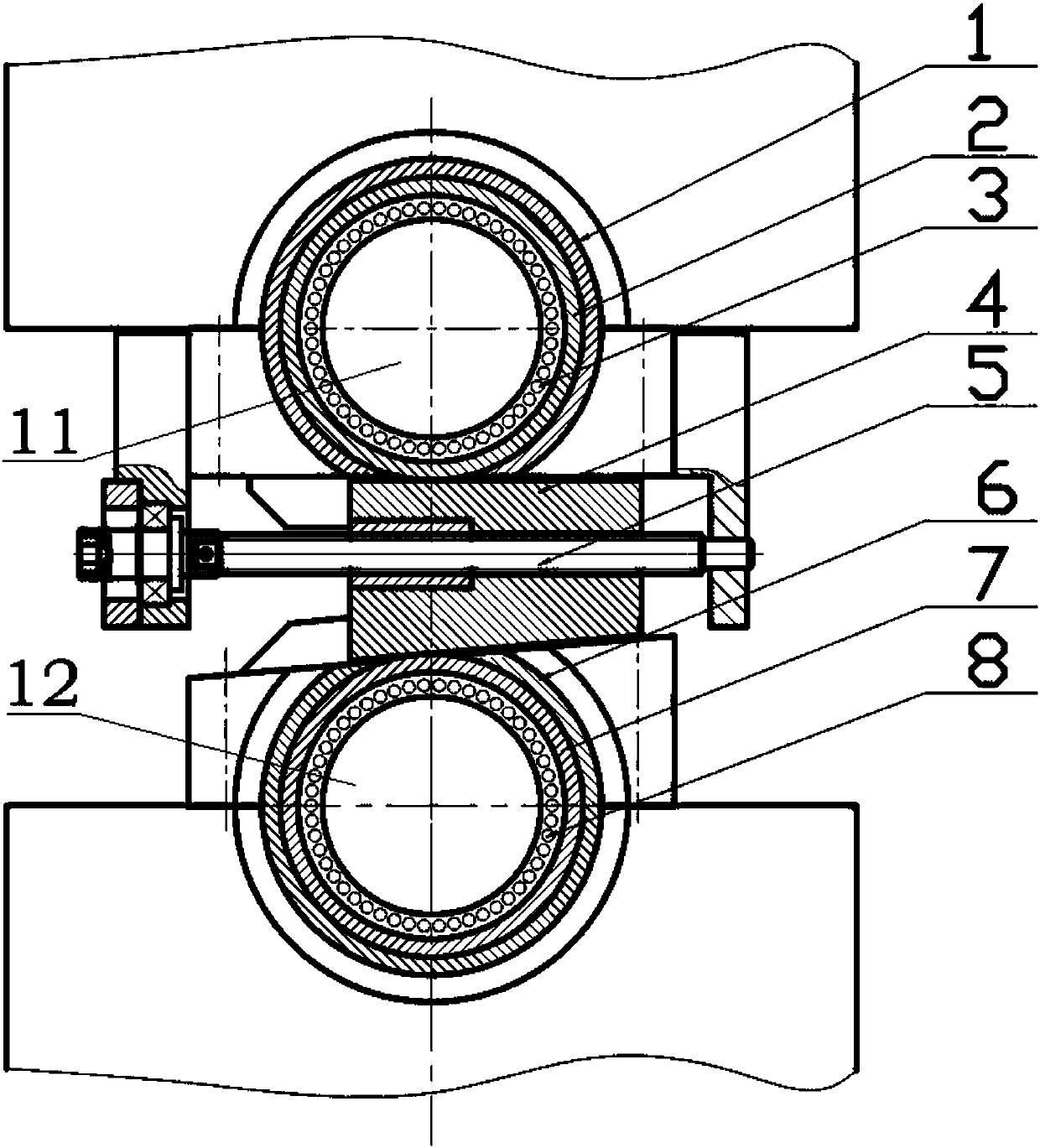

[0018] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

[0019] It should be noted that all expressions using "first" and "second" in the embodiments of the present invention are to distinguish two entities with the same name but different parameters or parameters that are not the same, see "first" and "second" It is only for the convenience of expression, and should not be construed as a limitation on the embodiments of the present invention, which will not be described one by one in the subsequent embodiments.

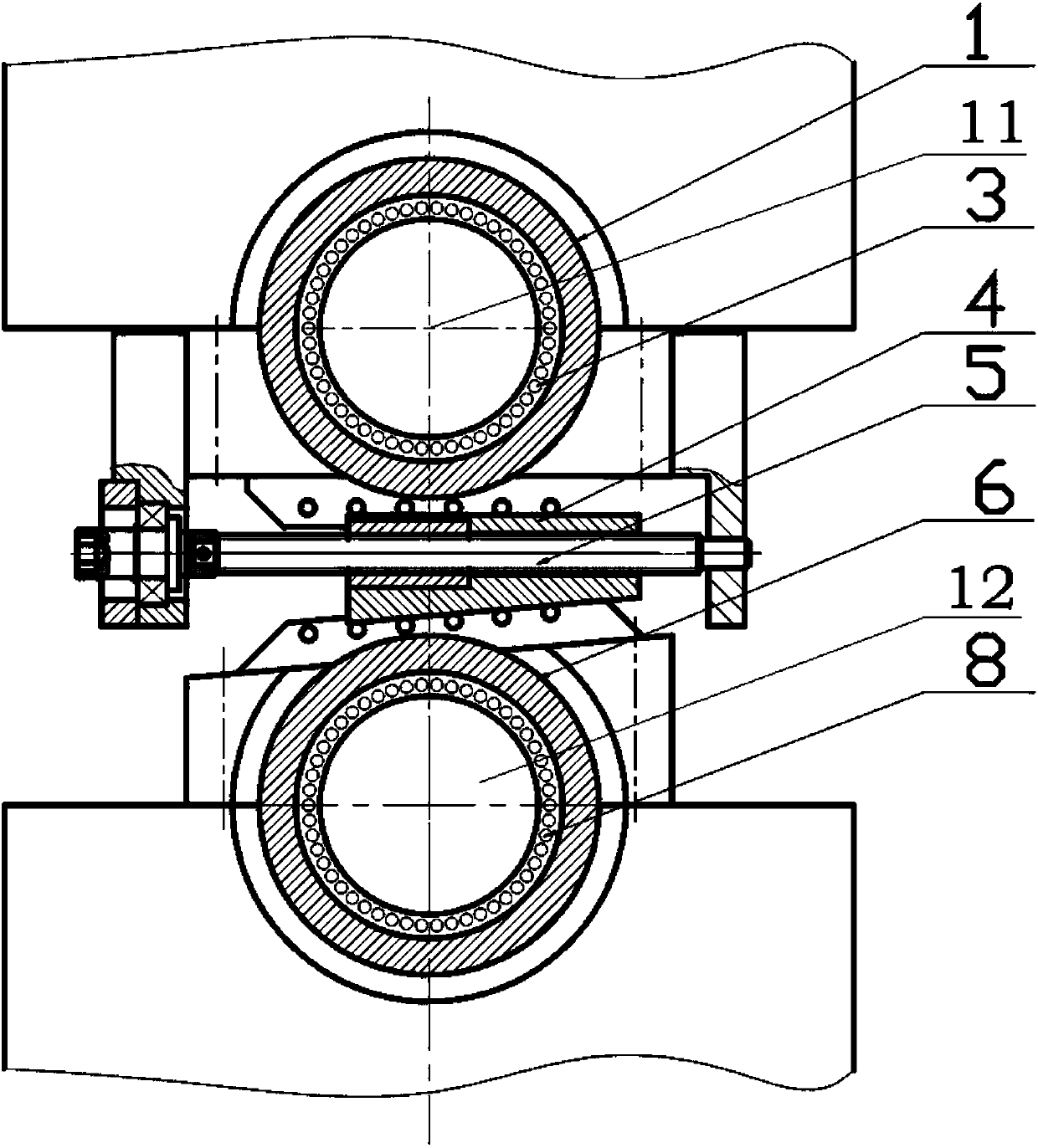

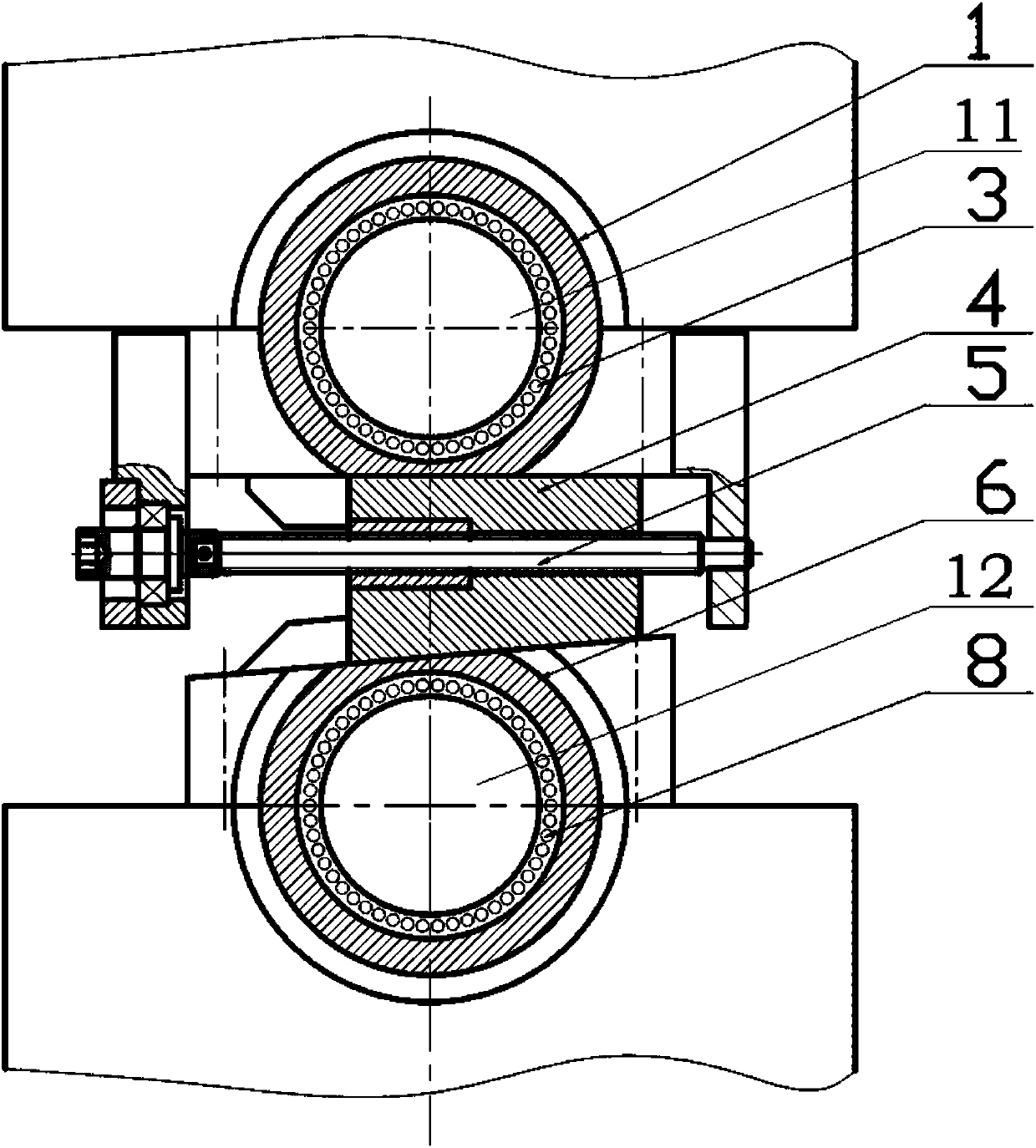

[0020] This application is aimed at the problems existing in the current adjustment of the axis spacing, for example: in the adjustment of the embossing shaft structure corresponding to printing by using the circular pressing circle structure, refer to figure 1 with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com