Screw cutting component of food sausage processor

A technology for cutting components and processing machines, which is applied in the field of cutting knife components, food sausage processing machine spiral cutting components, and sausage spiral cutting knife components. Simple, the effect of improving the uniformity of cutting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

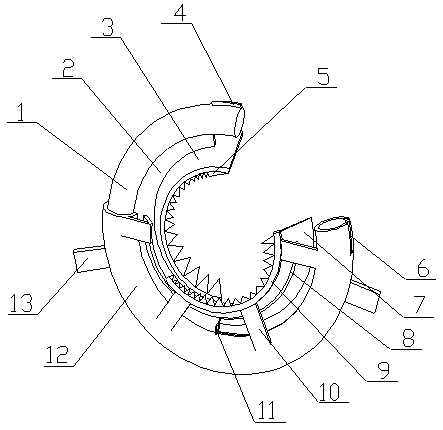

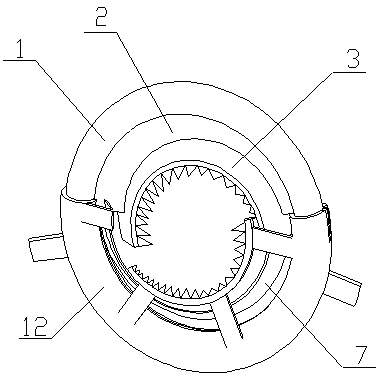

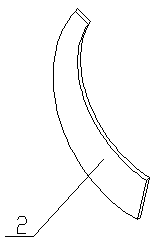

[0024] A spiral cutting member of a food sausage processing machine in the present invention is realized in this way. When in use, when performing spiral cutting on sausages, the present invention is first installed on the sausage processing machine, and the initial state is that the snap ring (1) is hidden in the fixed sleeve ( 12) Inside, and form a half-open structure, the main cutting arm (3) on the snap ring (1) and the auxiliary cutting arm (7) on the fixed sleeve (12) fit together, when the transmission device sends the sausage into the fixed sleeve (12) When inside, the worker pulls the snap ring (1) manually, so that the snap ring (1) extends outward along the fixed sleeve (12), and the snap ring (1) drives the connecting piece (2) and the main cutting arm (3) Movement, due to the eccentricity of the main cutting arm (3) and the snap ring (1), the eccentricity of the auxiliary cutting arm (7) and the fixed sleeve (12), with the deflection of the main cutting arm (3), t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com