Assembling and welding tool and steam cold separator barrel installing structure using tool

A technology for separators and welders, applied in auxiliary devices, manufacturing tools, welding equipment, etc., can solve the problems of inconvenient assembly and welding work, large volume, self-heavy large-scale steam-cooled separator cylinder, etc., and achieve convenient assembly and welding work Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

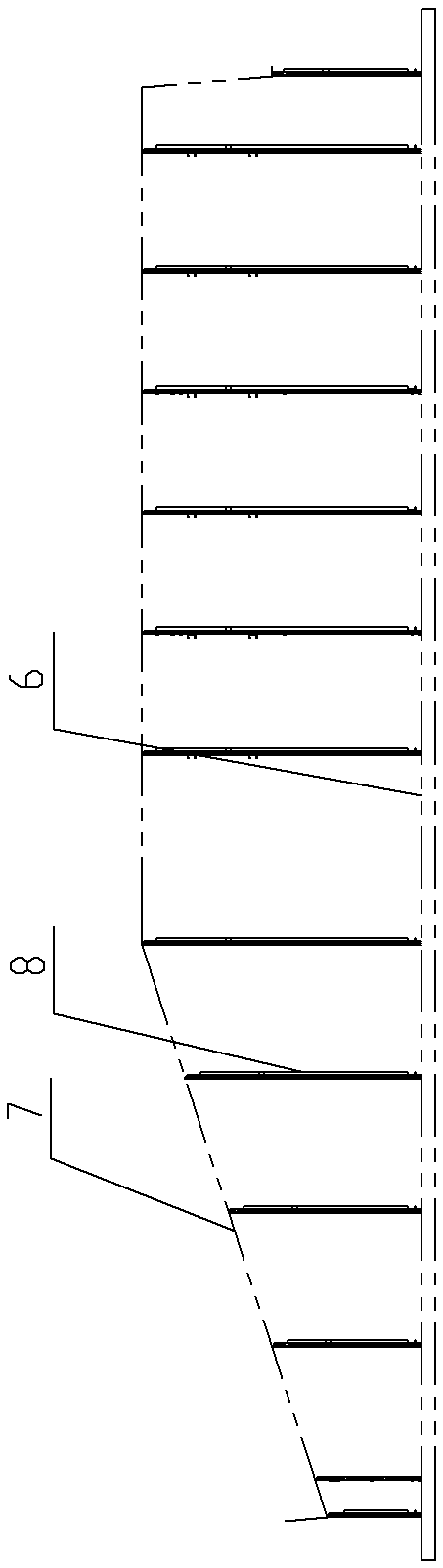

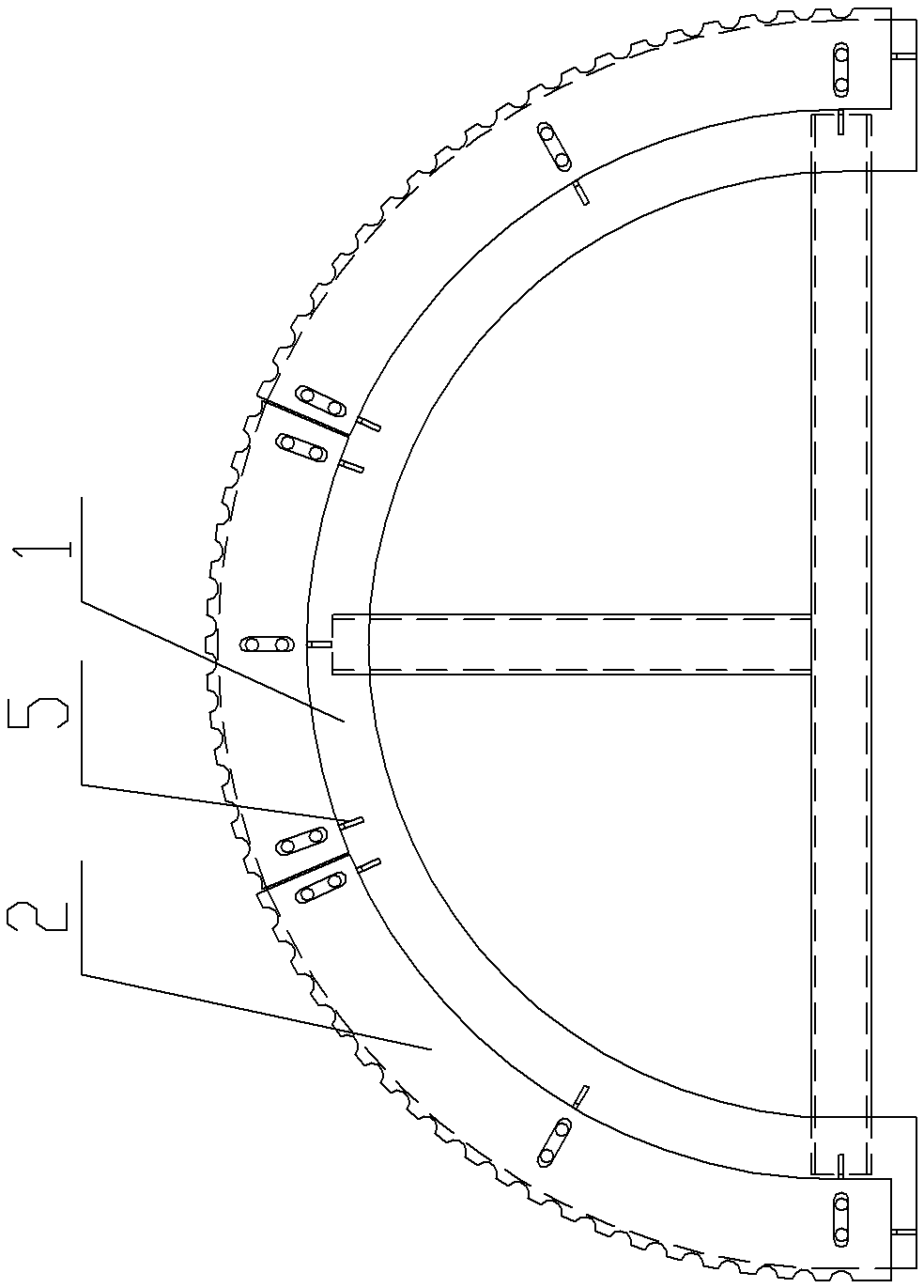

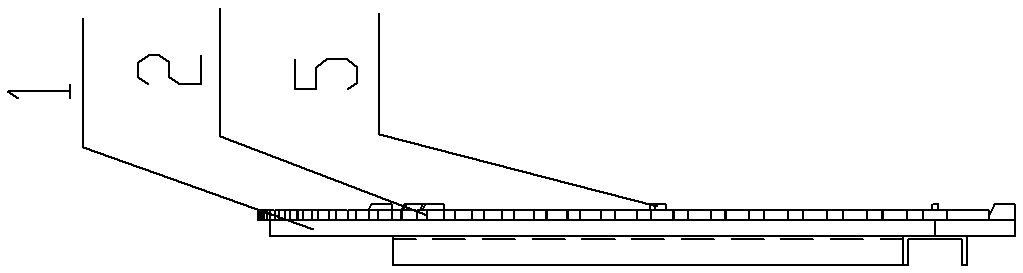

[0016] See figure 2 , image 3 , Figure 4 and Figure 5 As shown, a welding tooling includes a base plate 1 and an arc positioning plate 2. The arc positioning plate 2 is spliced by three arc blocks 2-1, and the outer peripheral surface of the arc positioning plate 2-1 has an arc Groove 2-2 plays a role in locating the separator pipe during assembly. The base plate 1 includes an arc plate 1-1 corresponding to the arc positioning plate 2 and a T-shaped supporting steel 1-2 connecting the arc plate 1-1.

[0017] The arc positioning plate 2 is provided with a first connection hole 3, and the arc plate 1-1 is provided with a second connection hole 4 corresponding to the first connection hole 3, and the arc positioning plate 2 and the arc plate 1-1 are connected by bolts. Nuts cooperate to realize the connection; the first connection hole 3 is a waist hole, and the second connection hole 4 is two threaded holes side by side; the arc positioning plate 2 and the arc plate 1-1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com