High-quality fin plate longitudinally-cutting mechanism

A high-quality, finned technology, applied in heat exchange equipment, etc., can solve the problems affecting the quality of the fins, easy to produce burrs, etc., and achieve the effects of improving production efficiency, reducing labor intensity, and improving fin quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The technical solutions of the present invention will be further described below in conjunction with the drawings and specific implementations. It can be understood that the embodiments described here are only used to explain the present invention, but not to limit the present invention.

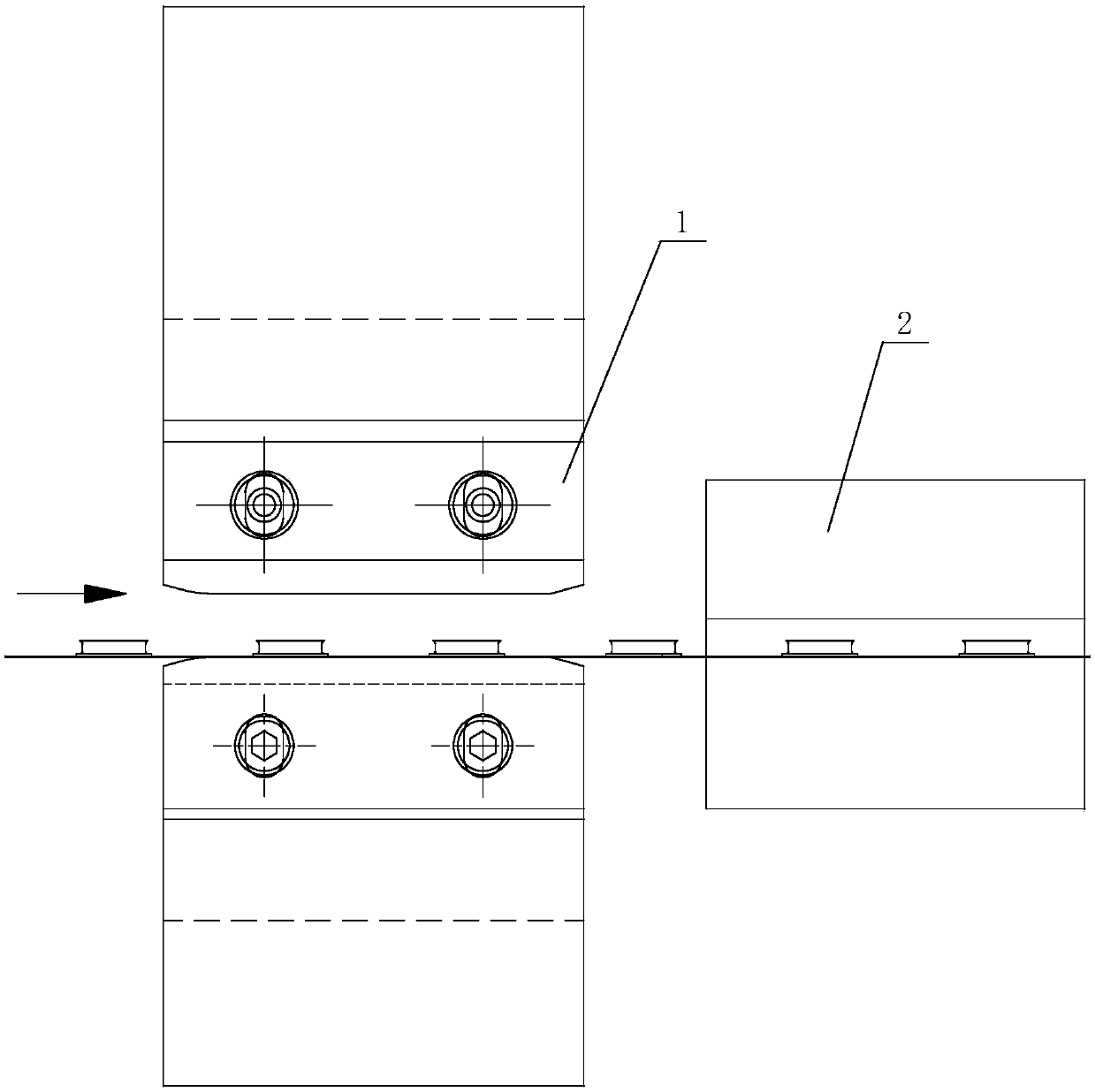

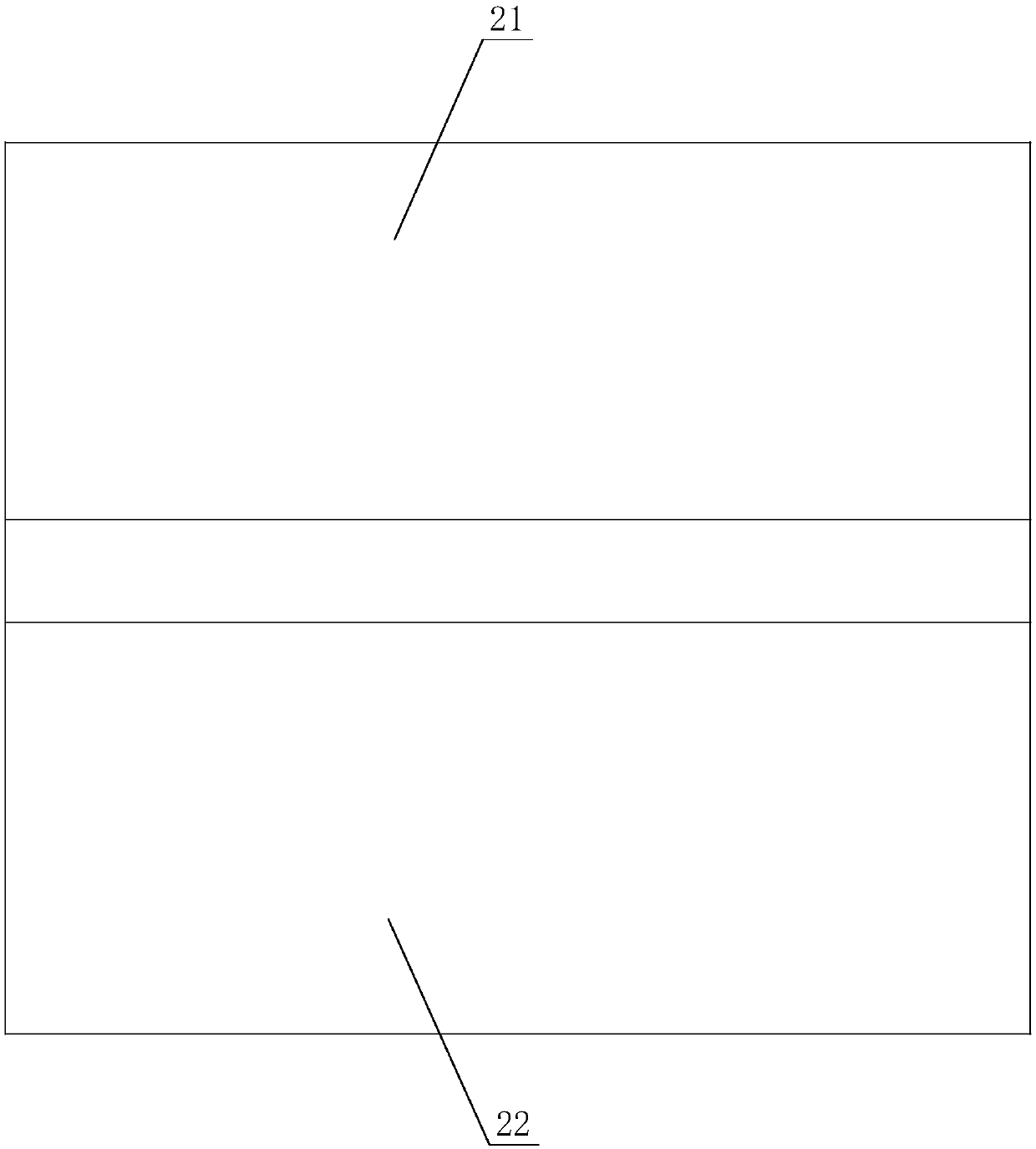

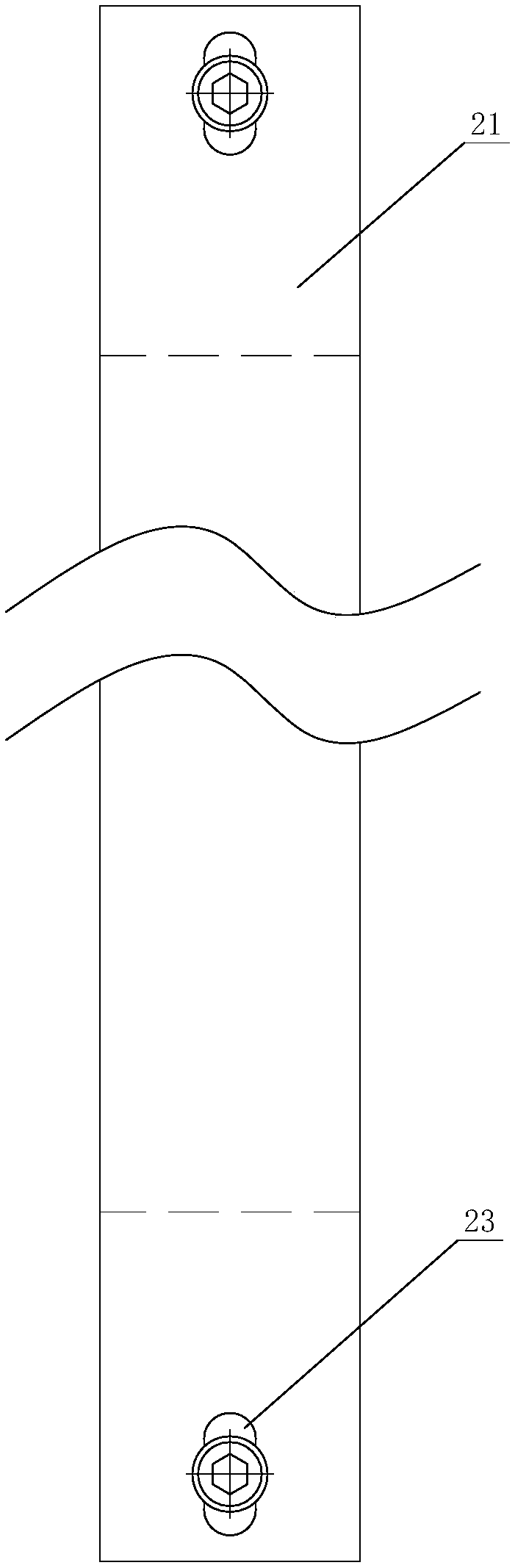

[0019] Please refer to Figure 1 to Figure 6 As shown, in this embodiment, a high-quality fin slitting mechanism includes a slitting die 1 and a guide assembly 2 arranged along the feeding direction. The guide assembly 2 includes a pressing plate 21 and a material lifter. A plate 22, the holding plate 21 is fixedly connected to the lifting plate 22 by bolts 24, the holding plate 21 is provided with a round hole 23, the lifting plate 22 is provided with threaded holes through which the bolts pass The waist round hole 23 is screwed into the threaded hole. The lower end surface of the pressing plate 21 is provided with a plurality of pressing teeth 25 for pressing down the fins, and the up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com