Gas turbine comprising a compressor casing with an inlet opening for tempering the compressor casing and use of the gas turbine

A technology for compressor casings and gas turbines, applied to parts of pumping devices for elastic fluids, machines/engines, mechanical equipment, etc., which can solve problems such as friction of rotor components

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

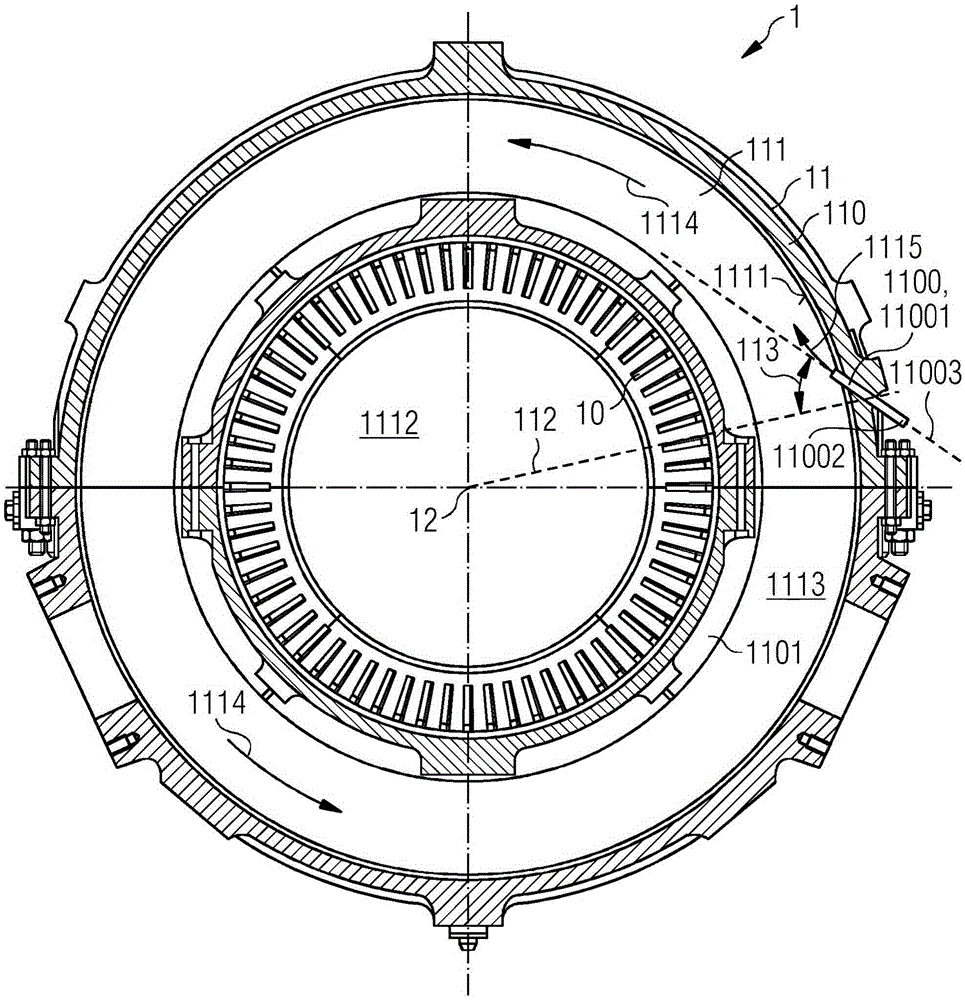

[0018] The subject is a turbine 1 comprising at least one rotor assembly 10 and at least one compressor housing 11 . Turbine 1 is a gas turbine. Combustion exhaust gas is the working fluid of the gas turbine 1 for driving the rotor assembly 10 of the turbine 1 .

[0019] The compressor housing comprises at least one inner compressor housing chamber 1112 for arranging the rotor assembly and at least one outer compressor housing chamber 1113 for compressor discharge air extraction. The rotor assembly is located in the inner compressor housing cavity such that the rotor assembly and the compressor housing are arranged coaxially with each other. These elements comprise a common axis of rotation 12 .

[0020] The inner compressor housing chamber 1112 and the outer compressor housing chamber 1113 are separated from each other by a partition housing wall 1101 . The outer compressor casing chamber 1113 includes at least one bounding casing wall 110 . The boundary housing wall 110 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com