Lifting device for installing large-sized stamping die

A stamping die and large-scale technology, which is applied in the field of installing large stamping die lifting devices, can solve the problems of workers being easily injured and life-threatening, and achieve the effects of good lifting stability, avoiding dangerous situations, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

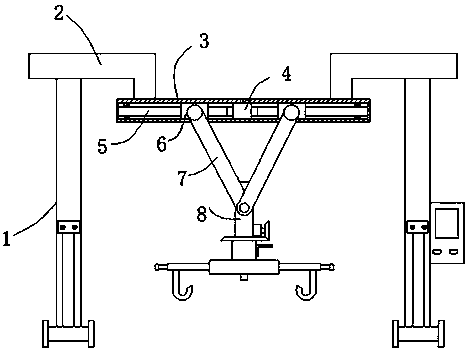

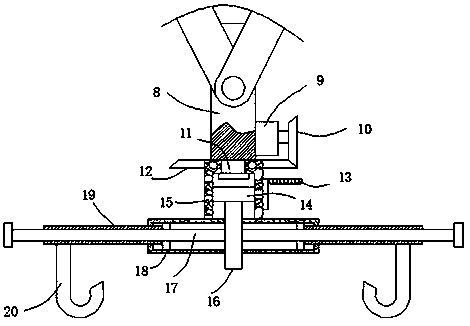

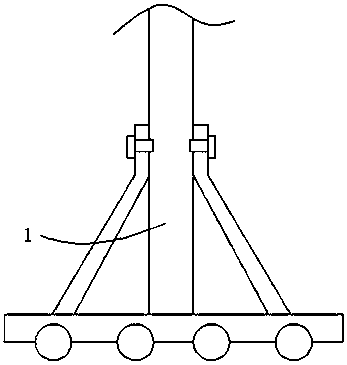

[0018] refer to Figure 1-3 , a lifting device for installing large stamping dies, comprising a set of triangular support frames 1 arranged in parallel, L-shaped fixed rods 2 arranged symmetrically between the triangular support frames 1, and the L-shaped fixed rods 2 are far away from the triangular supports One end of the frame 1 is fixed with a hollow mounting block 3, and the inner side of the hollow mounting block 3 is fixed with a double-headed motor 4, and the two output shafts of the double-headed motor 4 are fixed with a first threaded rod 5, and the first threaded rod 5 rotates the sleeve Connected to the inner side of the hollow mounting block 3, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com