Special-shaped bending device for copper pipes

A pipe and bending technology, which is applied in the field of special-shaped bending equipment for copper pipe fittings, can solve problems such as poor support stability, unsatisfactory bending quality of pipe fittings, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific embodiment of the present invention will be described in further detail below in conjunction with accompanying drawing, in order to have further understanding to the conception of the present invention, the technical problem solved, the technical feature that constitutes the technical solution and the technical effect that brings, it should be noted that , the descriptions of these embodiments are schematic and do not constitute a specific limitation to the present invention.

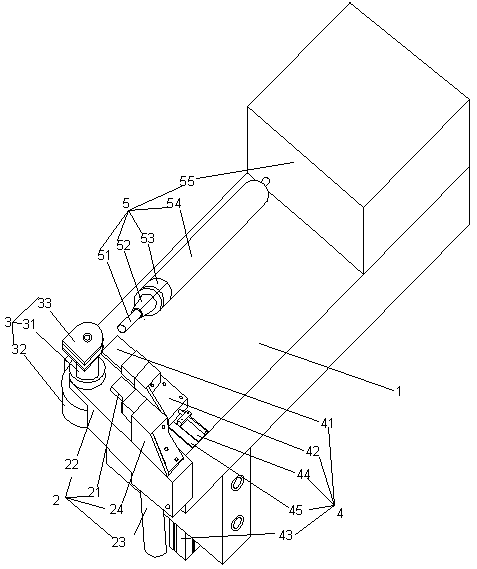

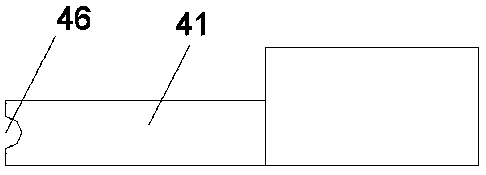

[0021] It can be seen from the figure that a special-shaped bending equipment for copper pipe fittings is characterized in that it includes a frame platform 1, a bending mechanism 2, a rotating mechanism 3, a positioning mechanism 4 and a shifting mechanism arranged on the frame platform 5;

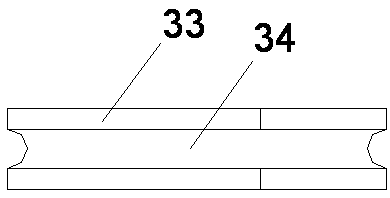

[0022] The rotating mechanism 3 includes a rotating shaft 31, a rotating base 32 and a guide block 33, the rotating base 32 is fixedly installed on the frame platform 1, and the rotating shaft 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com