Continuous liquid preparing device for medical supply room

A supply room and liquid mixing technology, which is applied to mixers with rotating stirring devices, transportation and packaging, mixer accessories, etc., can solve the problems of waste of disinfectant, low efficiency of liquid mixing, uneven mixing, etc., and achieve shortening of liquid mixing Time, waste avoidance, effects of spatter prevention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

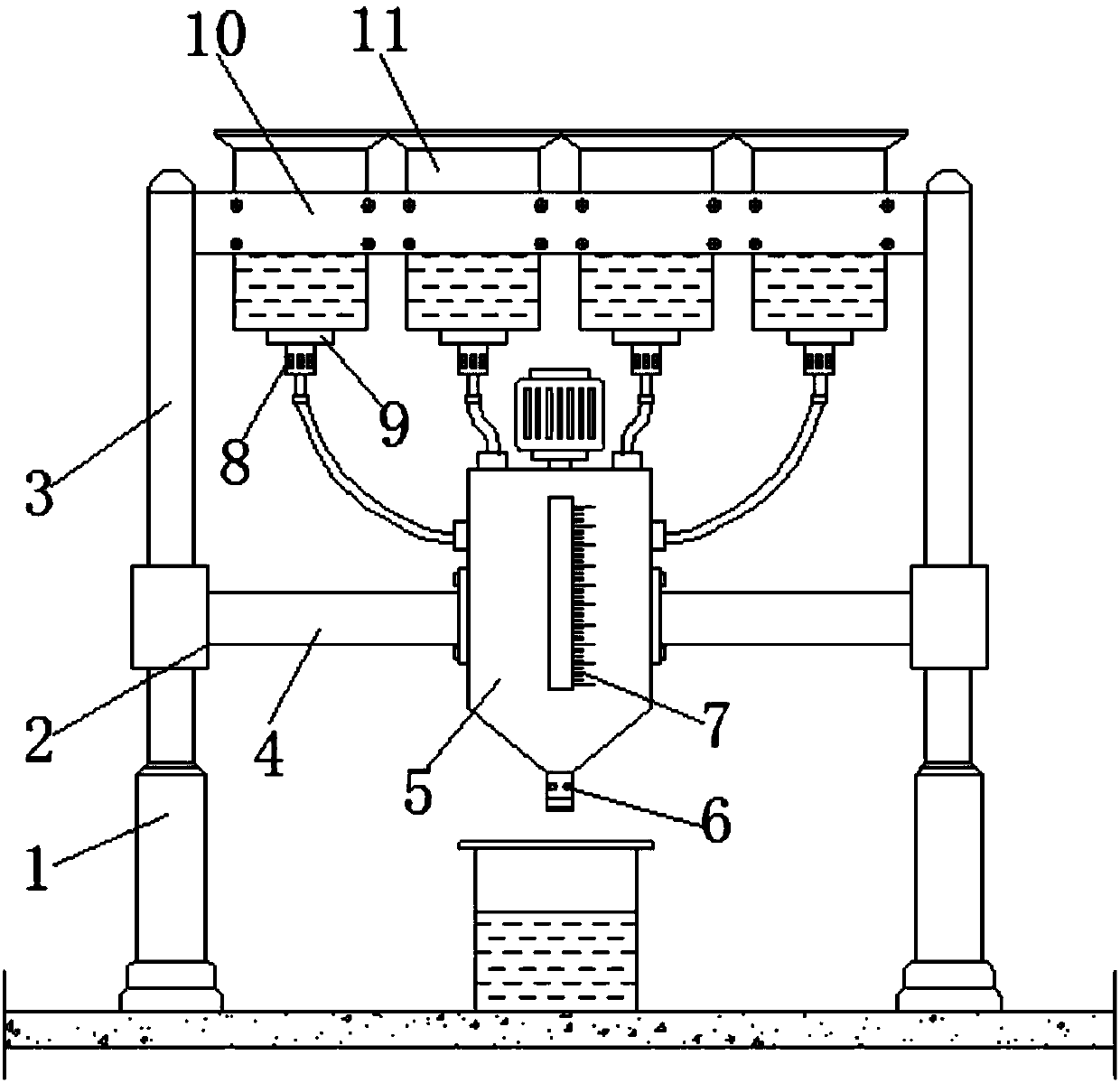

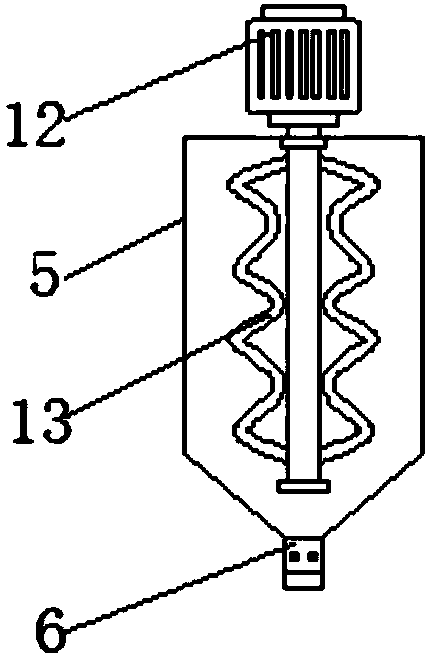

[0019] refer to Figure 1-2 , a continuous liquid dispensing device for medical supply rooms, including a liquid dispensing device body 2, a liquid mixing chamber 5 and a liquid storage chamber 11, XTL100 electric telescopic rods 1 and XTL100 electric telescopic rods are arranged symmetrically on both sides of the bottom of the liquid dispensing device body 2 The top of 1 is welded with a support rod 3, and the support rods 3 are fixedly connected to the liquid storage bin 11 through the fixed rod 10, and the second solenoid valve 9 and the flow rate Meter 8, the bottom of flowmeter 8 communicates with mixing chamber 5 through flexible pipe, and the inside of mixing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com