Calibrating test bench for thin oil film detection with ultrasonic wave

A technology of ultrasonic wave and thin oil film, which is applied in the direction of using ultrasonic wave/sonic wave/infrasonic wave, measuring device, instrument, etc., to achieve the effect of diverse device measurement, stable device structure and precise adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

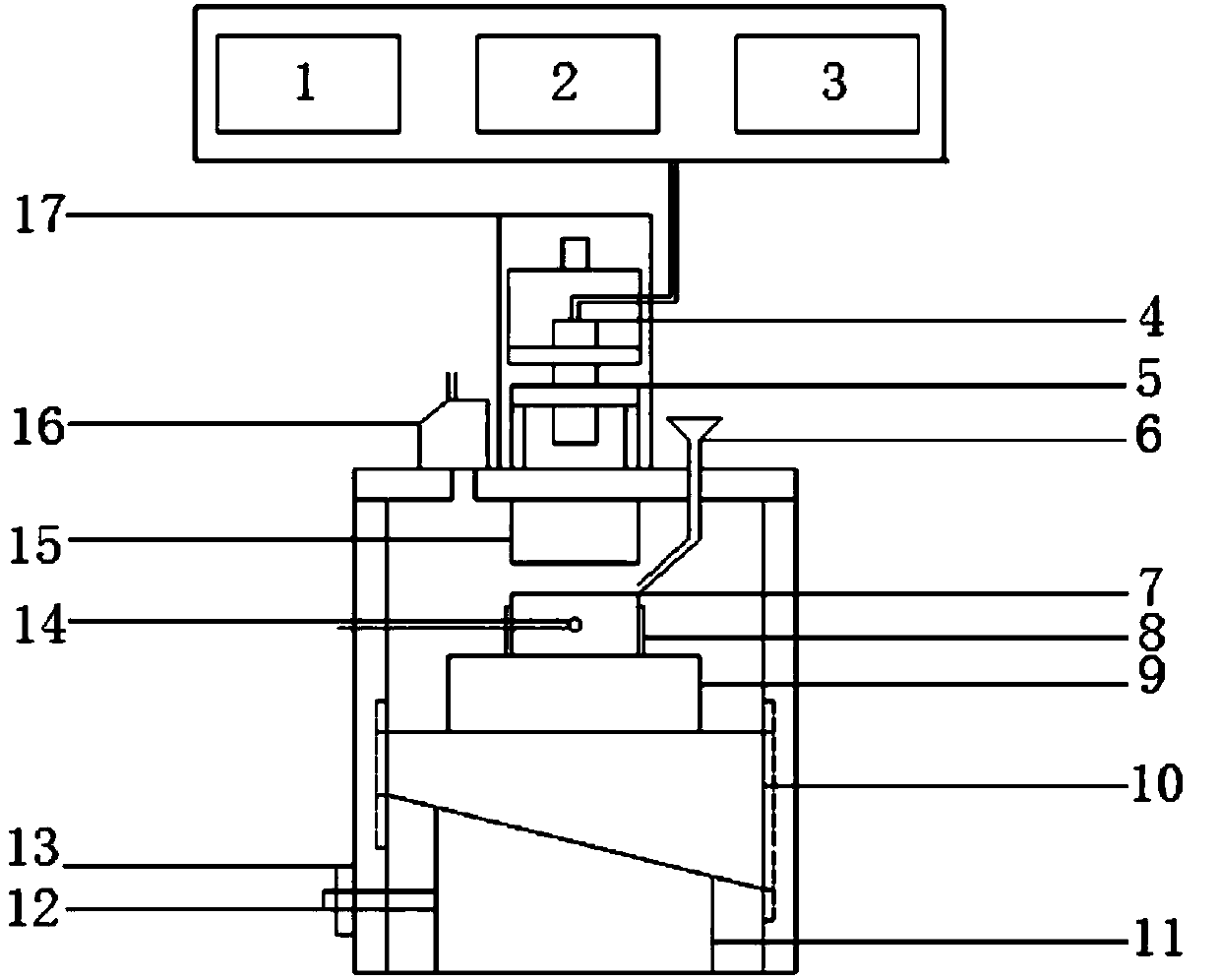

[0023] The present invention is described in more detail below in conjunction with accompanying drawing example:

[0024] combine figure 1 , a calibration test bench for measuring the thickness of thin oil film by ultrasonic wave of the present invention, comprising ultrasonic transmitting and receiving devices 1, 2, water immersion type ultrasonic probe 4, water tank 5, bench, oil film upper block 15, oil film lower block 7, platform 9 , displacement sensor 16, platform adjustment 17, upper wedge 10, lower wedge 11, screw rod, nut 13 and other components. The probe is fixed on the upper plane of the water tank 5 . The ultrasonic emitting and receiving device includes: an ultrasonic emitting device 1 , an ultrasonic receiving device 2 and a computer 3 . Screw rod is fixed together with lower wedge 11 left ends. Block 7 under the oil film can be heated.

[0025] The rotation of the screw pushes the lower wedge 11 to move laterally, so that the height of the upper wedge 10 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com