Prestress grid industrial material field awning

A prestressed and industrial technology, applied in the field of prestressed grid industrial material yard canopy, can solve problems such as increasing the basic cost, and achieve the effect of reducing the basic cost, increasing its own rigidity, and avoiding the excessively large cross-section of the rod.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

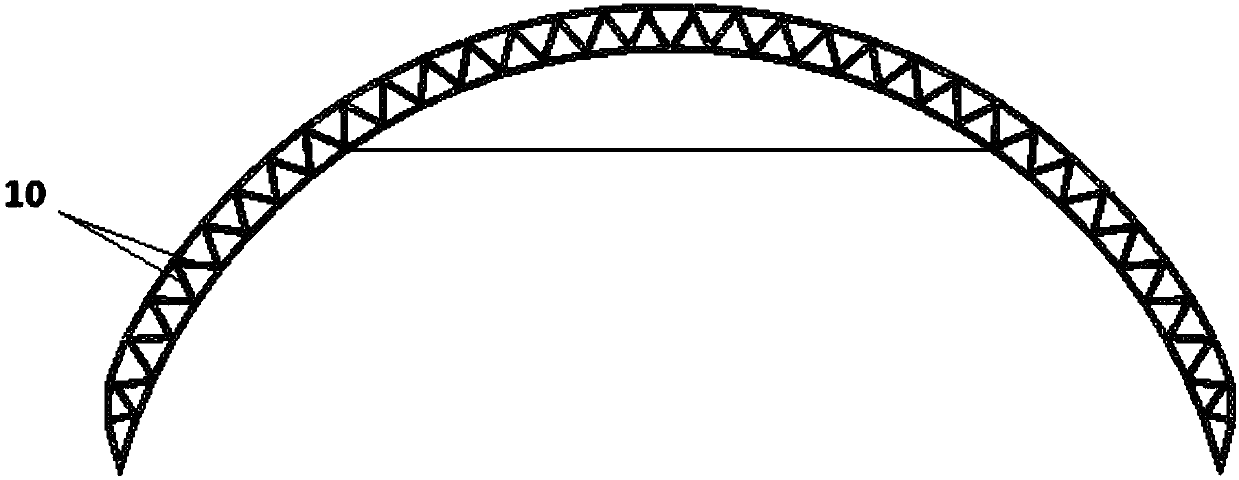

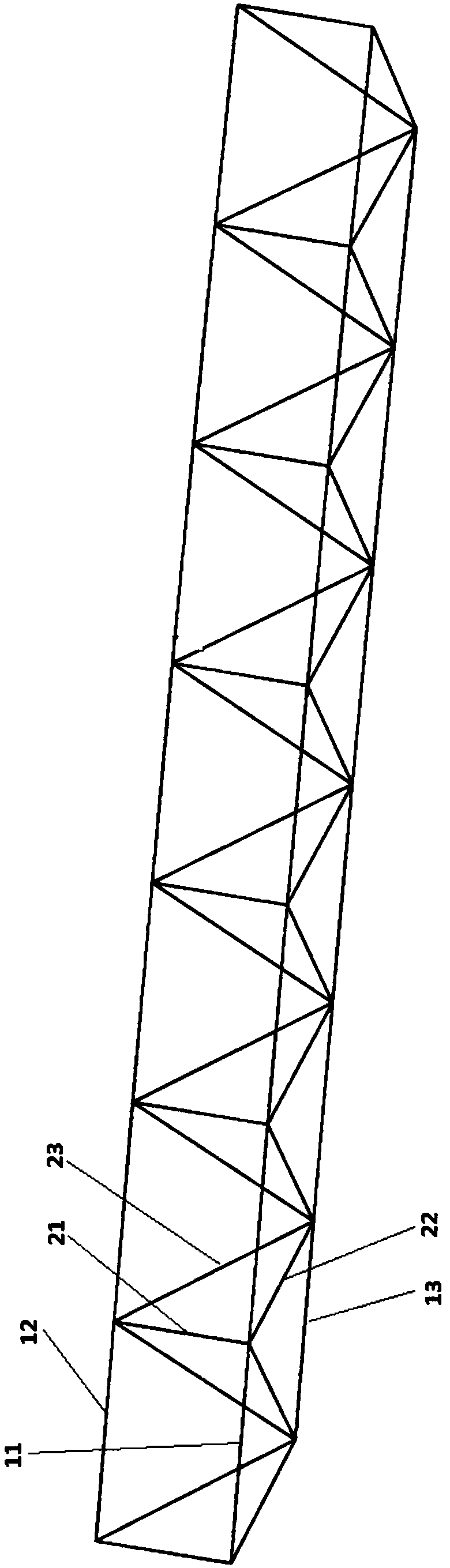

[0020] Such as figure 1 and figure 2 As shown, the embodiment of the present invention provides a kind of prestressed grid industrial material yard shed, including the upper chord, the lower chord, the web and the secondary truss, and the upper chord, the lower chord, the web and the secondary truss are all composed of at least one rod assembly 10, and each rod assembly 10 includes a plurality of rod units.

[0021] Changing the upper chord, lower chord, web and secondary truss from a single member to a grid structure composed of multiple member units can effectively increase the stiffness of the structure itself and avoid excessive cross-section of the member as the span increases In order...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com