Hub with tire burst emergency device

An emergency device and tire puncture technology, applied in the direction of hubs, rims, tire parts, etc., can solve the problems of resource reset, high cost, high fuel consumption, and achieve the effect of economical manufacturing process, lightening rim weight, and reducing product cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

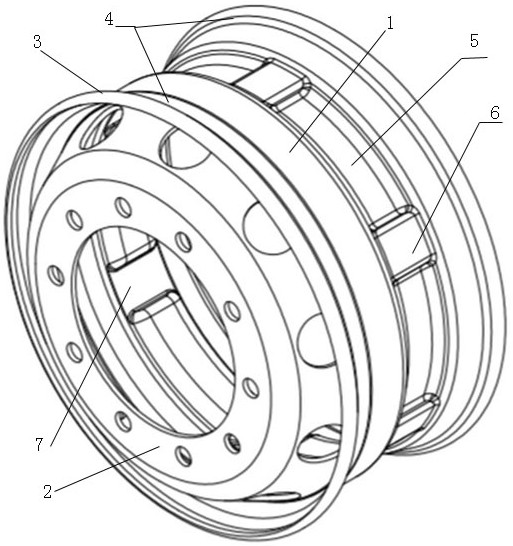

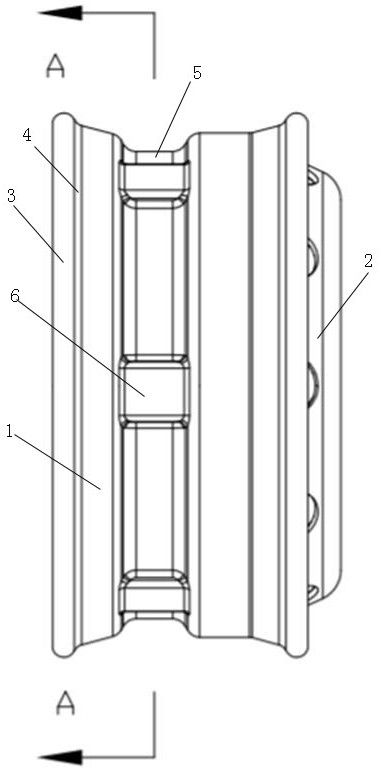

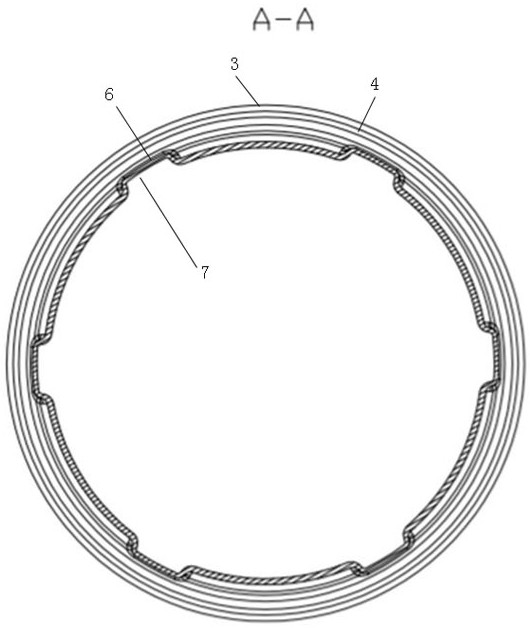

[0027] The present invention as Figure 1-3 shown.

[0028] A wheel hub with a self-contained tire burst emergency device, including a car wheel hub, the car wheel hub also includes a rim 1 and a spoke 2, the spoke 2 supports the rim 1, and the rim 1 is provided with a bead seat 4 through the rim 3, The bottom of the rim 1 also includes an annular groove ring 5, on which a plurality of uniform protrusions 6 are directly arranged, and the plurality of protrusions 6 form a tire burst emergency safety device on the annular groove ring 5. device.

[0029] The plurality of protrusions 6 form a tooth structure and are arranged in a staggered manner.

[0030] The plurality of protrusions 6 may be in the form of a rectangle, and are arranged axially on the annular groove ring 5 to form a staggered layout.

[0031] The plurality of protrusions 6 are made by rolling, spinning or stamping on the annular groove ring 5, and grooves 7 are correspondingly formed on the other side of the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com