Assembling method of truss bridge segments

A truss bridge and segment technology is applied in the field of truss bridge segment assembly, which can solve the problem that large-span steel truss girders cannot be assembled in large quantities, and achieve the effects of improving assembly quality, reducing high-altitude operations, and speeding up assembly speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

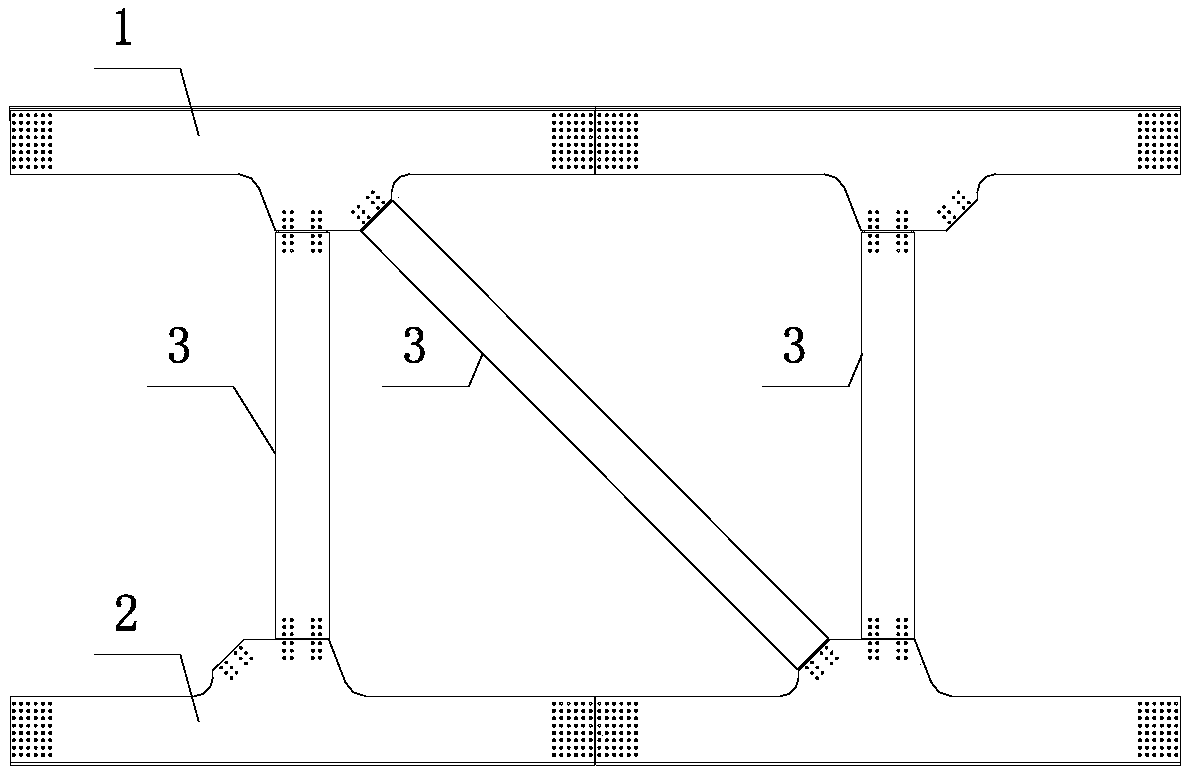

[0035] The embodiment of the present application provides a method for assembling truss bridge segments, which solves the problem of assembling the truss bridge segments sequentially at the bridge position in the prior art, which cannot be applied to the large-scale assembly of large-span steel truss girders. technical problem.

[0036] The technical solution in the embodiment of the present application is to solve the above-mentioned technical problems, and the general idea is as follows:

[0037] Based on the traditional technology and the structural characteristics of steel truss girders, this application proposes three-dimensional assembly in the infield, and then overall hoisting in turn, adjusting the line shape, and performing circular joint connection. The overall assembly of the body can reduce high-altitude operations, improve efficiency, improve assembly quality, speed up assembly, meet the requirements of standardized mass production of large-span steel truss girde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com