A preparing method of a cassava polysaccharide-iron complex

A cassava polysaccharide and cassava starch technology, which is applied in the field of fine chemicals, can solve the problems of high toxicity, high by-product glucose, and production safety hazards, so as to improve the ability of comprehensive utilization, reduce the production of glucose, and eliminate production safety hazards. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

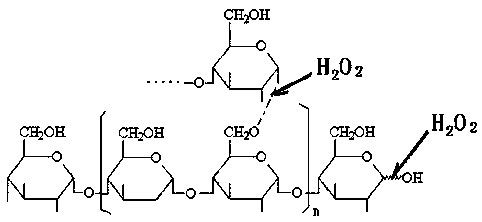

[0037] (1) Hydrogen peroxide oxidatively degrades tapioca starch to prepare suitable oligosaccharides: In a 200L enamel reaction kettle, start stirring, add 75.0 kg of water and 22.0 kg of tapioca starch, heat up to 60°C, and add 27.5% hydrogen peroxide 7.5 kg of solution, then heated up to 80°C, kept at a constant temperature, and carried out oxidation reaction for 60 minutes, when the reaction time was up, then added 29% sodium hydroxide seasoning solution with a pH value of 7.6, to obtain the suitable low-density compound with a weight average molecular weight of 4000-27000Da. polysaccharide solution.

[0038] (2) Complexation reaction: keep stirring, heat the prepared suitable oligosaccharide solution to 90°C, keep constant temperature, add 52 liters of 39.0% ferric chloride solution and 56 liters of 29.0% sodium hydroxide solution at the same time, Added within 3 hours. After adding the materials, adjust the pH value of the complexation reaction solution to 7.3 with 20% ...

Embodiment 2

[0043] ⑴ Hydrogen peroxide oxidatively degrades tapioca starch to prepare suitable oligosaccharides: In a 200L enamel reaction kettle, start stirring, add 80.0 kg of water and 22.0 kg of tapioca starch, heat up to 60°C, and add 27.5% hydrogen peroxide solution 8.5 kg, then raise the temperature to 88°C, keep the constant temperature, carry out the oxidation reaction for 45 minutes, when the reaction time is up, add 29% sodium hydroxide seasoning solution and the pH value is 7.2, that is, the suitable oligomer with a weight average molecular weight of 4000-27000Da sugar solution.

[0044] (2) Complexation reaction: keep stirring, heat the prepared suitable oligosaccharide solution to 95°C, keep the constant temperature, add 52 liters of 39.0% ferric chloride solution and 56 liters of 29.0% sodium hydroxide solution at the same time, in 2.5 hours Added. After adding the materials, adjust the pH value of the complexation reaction solution to 7.6 with 20% hydrochloric acid to obt...

Embodiment 3

[0049] ⑴ Hydrogen peroxide oxidatively degrades tapioca starch to prepare suitable oligosaccharides: In a 200L enamel reaction kettle, start stirring, add 85.0 kg of water and 22.0 kg of tapioca starch, heat up to 60°C, add 27.5% hydrogen peroxide solution 9.5 Then raise the temperature to 95°C, keep constant temperature, carry out the oxidation reaction for 30 minutes, when the reaction time is up, add 29% sodium hydroxide seasoning solution with a pH value of 8.0, and obtain suitable oligosaccharides with a weight average molecular weight of 4000-27000Da solution.

[0050] (2) Complexation reaction: keep stirring, heat the prepared suitable oligosaccharide solution to 85°C, keep a constant temperature, add 52 liters of 39.0% ferric chloride solution and 56 liters of 29.0% sodium hydroxide solution at the same time, in 2 Added within hours. After adding the materials, adjust the pH value of the complexation reaction solution to 8.0 with 20% hydrochloric acid to obtain the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com