Hoisting locking mechanism and lifting appliance of highway-railway combined transportation van semitrailer

A technology of road-rail combined transport and semi-trailer, which is applied in the direction of trolley cranes, transportation and packaging, cranes, etc. It can solve the problems that van-type semi-trailers cannot be hoisted into railway wagons, etc., and achieve simple structure, wide application range, and safe hoisting operations Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

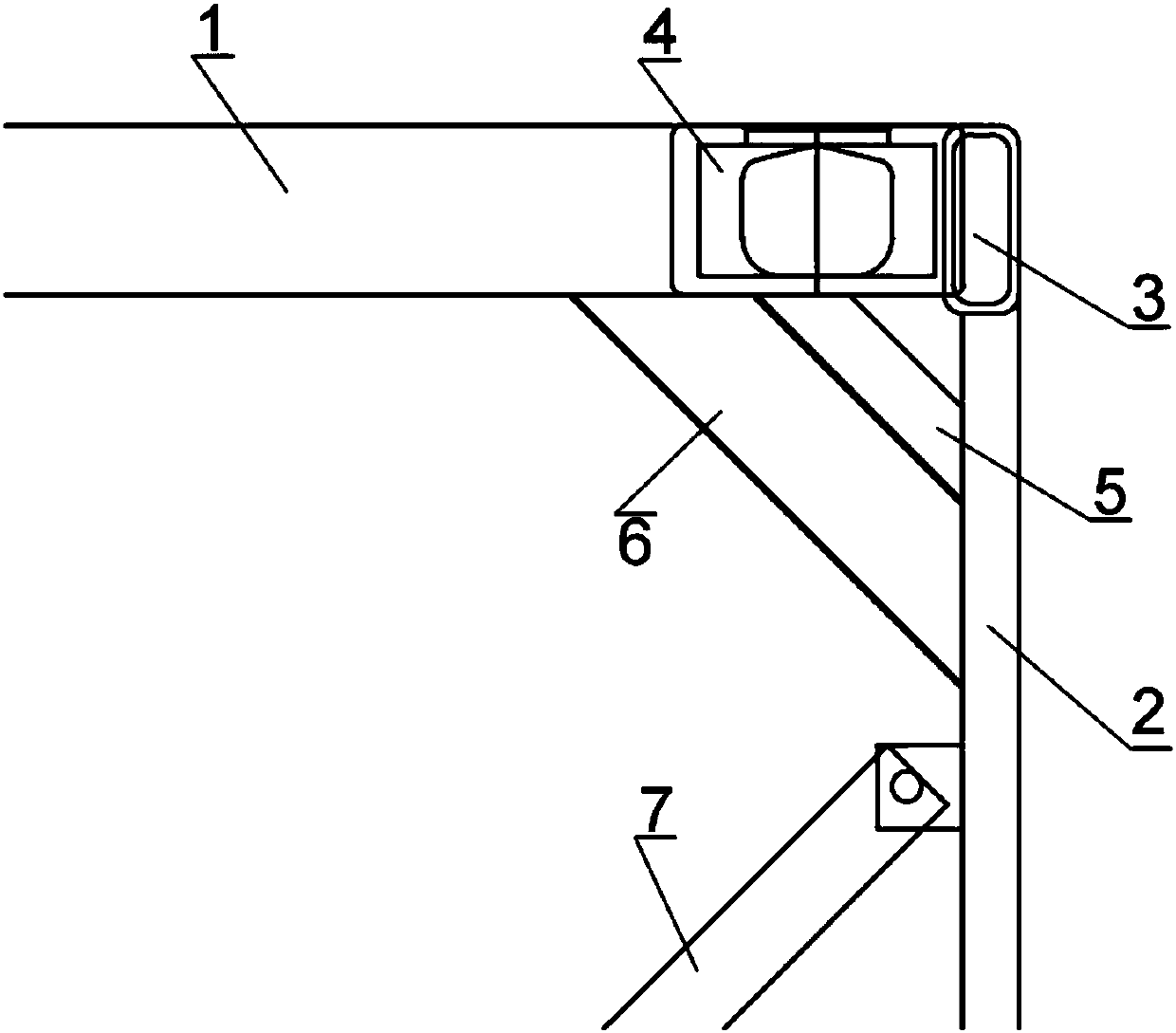

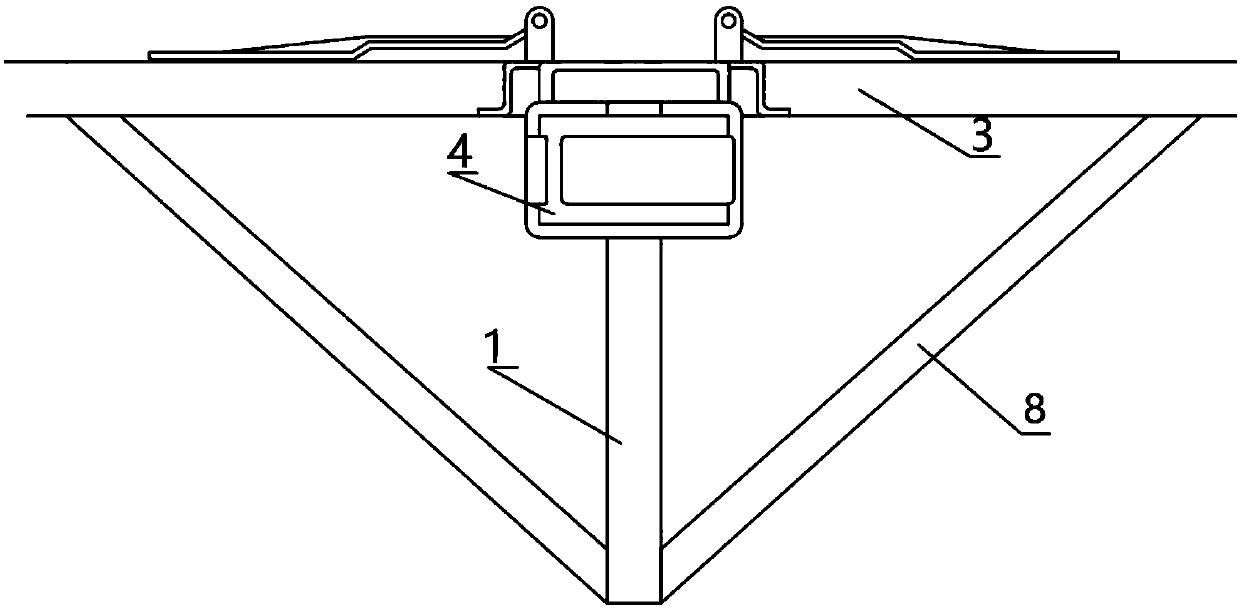

[0034] The present invention is a hoisting and locking mechanism and sling for a road-rail intermodal van semi-trailer, wherein the locking mechanism includes: container corner pieces 4, beams 1, bracing 5, diagonal bracing 6, channel steel diagonal bracing 7 and Crossbeam diagonal rod 8; among them, the spreader is a combined universal spreader that is combined with two different specifications of spreaders and can be quickly assembled and disassembled.

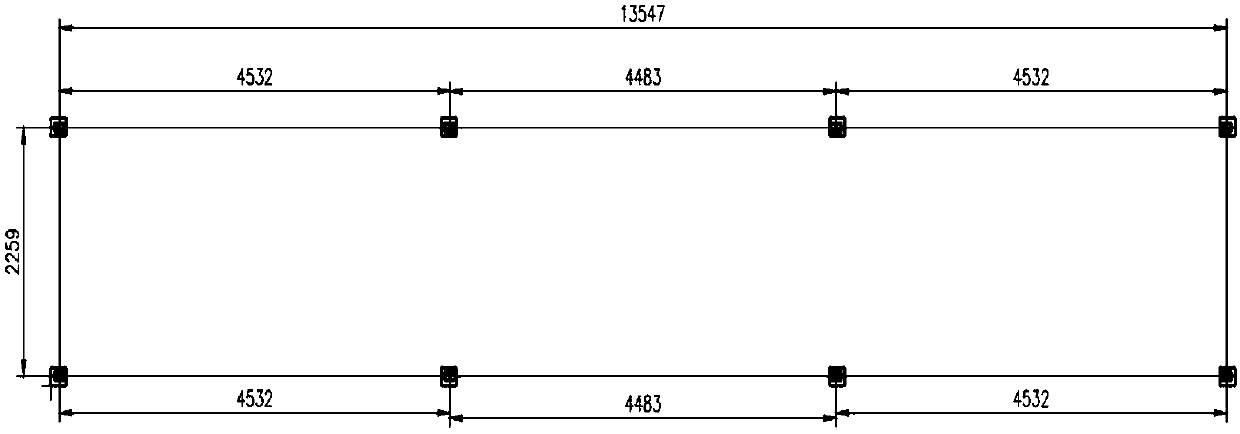

[0035] Such as figure 1 , 2 As shown in, 3 and 4, the container corner pieces 4 are arranged at 4 corners and 4 points in the middle of the top edge of the van semi-trailer, a total of 8 places, in which the horizontal position interval of the container corner pieces is 2259mm wide, and the longitudinal position interval is respectively 4532mm, 4438mm, 4532mm; the container corner piece 4 is welded to the side wall 3 of the van semi-trailer. Because the side wall 3 is welded together with the column 2 of the van semi-trailer, it...

Embodiment 2

[0038] Such as Figure 5 , Image 6 As shown, the present invention is a hoisting and locking mechanism and sling for a road-rail intermodal van semi-trailer, wherein the locking mechanism includes: a container corner piece 4 and a beam 1; wherein the sling consists of two different specifications It is a combined special spreader that can be assembled and disassembled quickly.

[0039] The locking mechanism is similar to the first type of locking mechanism, but in order to reduce the self-weight and welding process caused by structural reinforcement; and can make the semi-trailer column fully stressed during lifting; at the expense of being able to be used with containers, Move the 8 corner pieces to the top of the corresponding column of the van semi-trailer, that is, the container corner pieces 4 are arranged on the top edge of the van semi-trailer at 4 corners and 4 points in the middle, totally 8 places, and are located on the column 2 Above; the horizontal position spacing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com