Rolling type flat adhesive tape sticking device

A rolling device and tape sticking technology, which is applied in the direction of transportation and packaging, sending objects, thin material processing, etc., can solve the problems of low precision, inaccurate size control, and the edge of the glued tape is easy to warp and curl. The effect of high control precision, saving processing space and compact overall structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

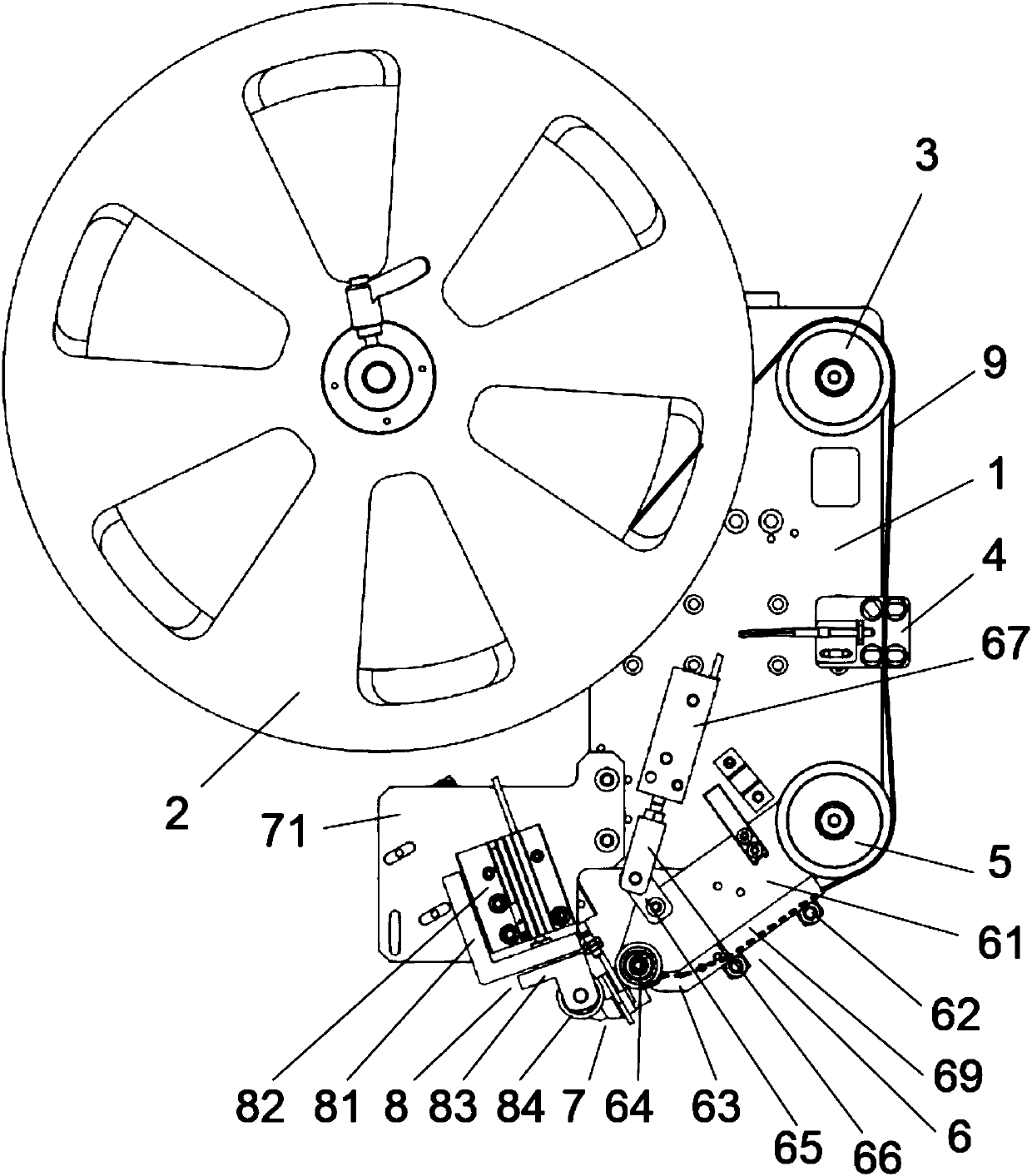

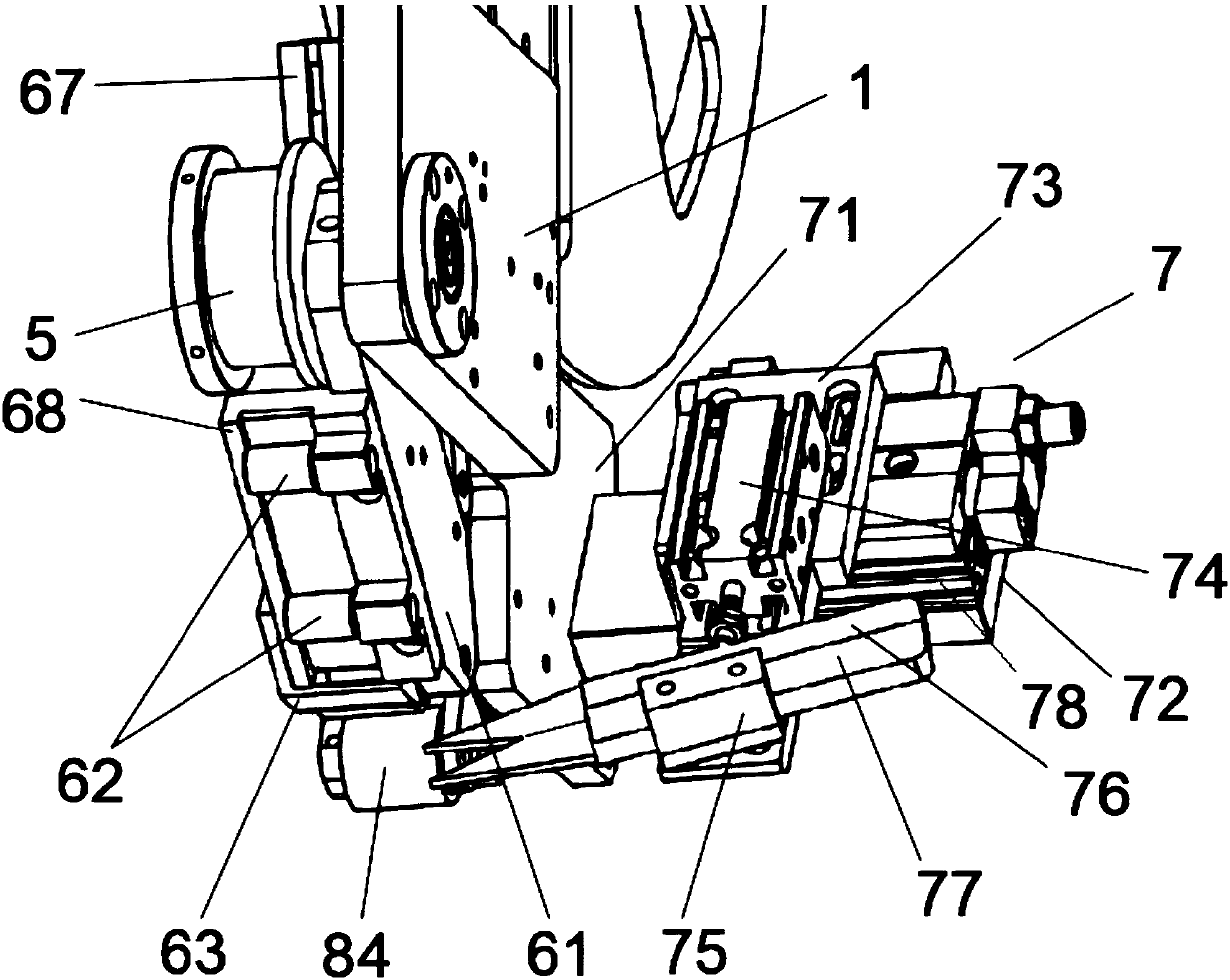

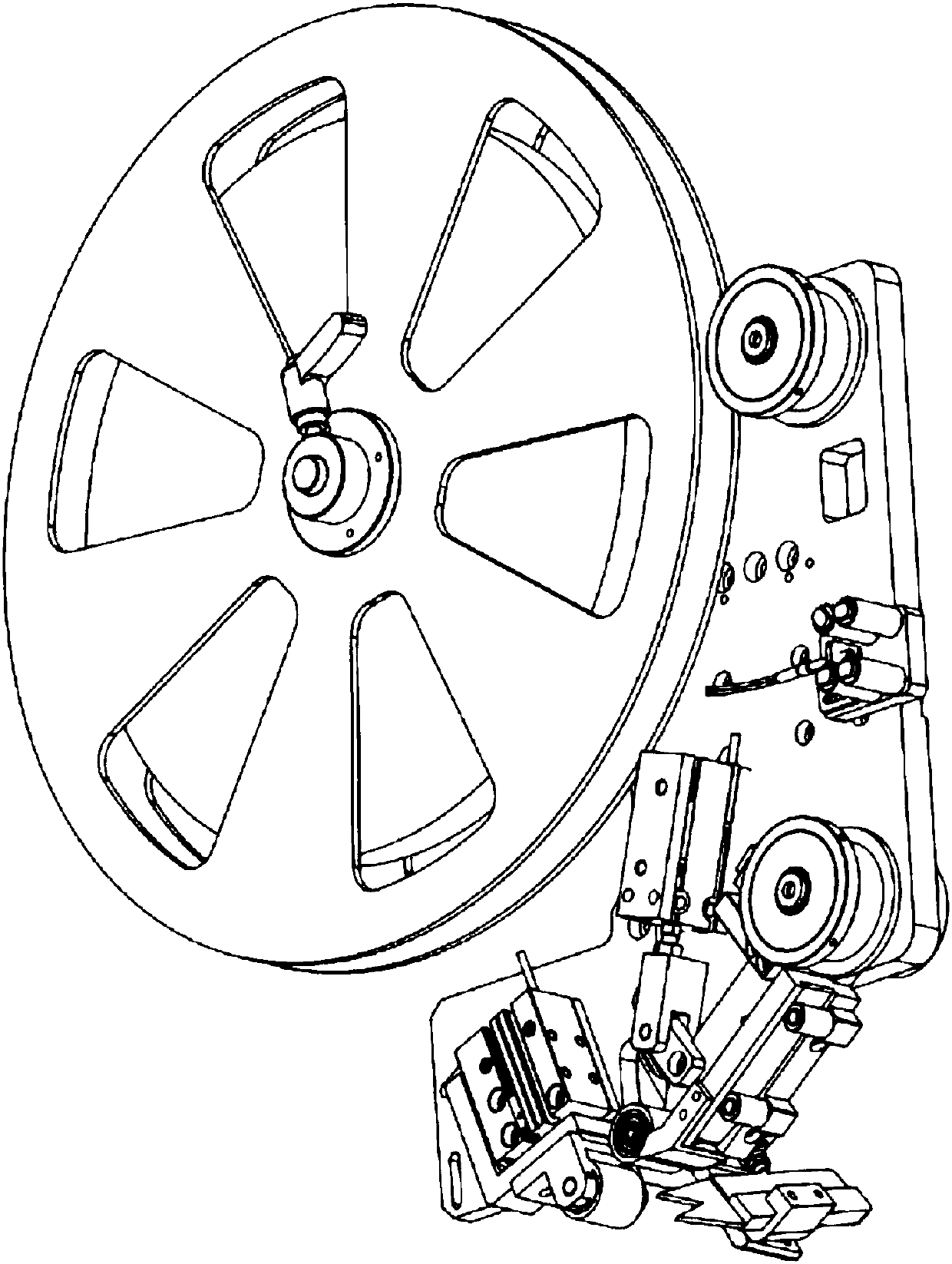

[0018] Such as Figure 1 to Figure 3 As shown, the present embodiment provides a rolling type flat tape sticking device, which includes a mounting plate 1; a feeding tray 2 is fixed on the upper left of the mounting plate 1, a first guide roller 3 is fixed on the upper right, and a right end A sensor 4 is fixed in the middle of the position, and a second guide roller 5 is fixed on the lower right; a rolling device 6 is arranged on the left side of the second guide roller 5, and a shearing device 7 is fixed on the left side of the rolling device 6 and leveling device 8; the rolling device 6 includes a rolling fixing plate 61, one end of the rolling fixing plate 61 is fixed on the shaft between the second guide roller 5 and the mounting plate 1, and the other end is fixed with a rolling Wheel 64; the bottom side of the rolling fixed plate 61 is fixed with a channel plate 68; the position to the left and the position to the right of the bottom side of the channel plate 68 are res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com