Vibration damping automobile luggage rack

A car luggage rack and luggage technology, which is applied in the field of shock-absorbing car luggage racks, can solve the problems of poor damping effect of the luggage rack and luggage damage, etc., and achieve the effects of good anti-aging effect, not easy to rot, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

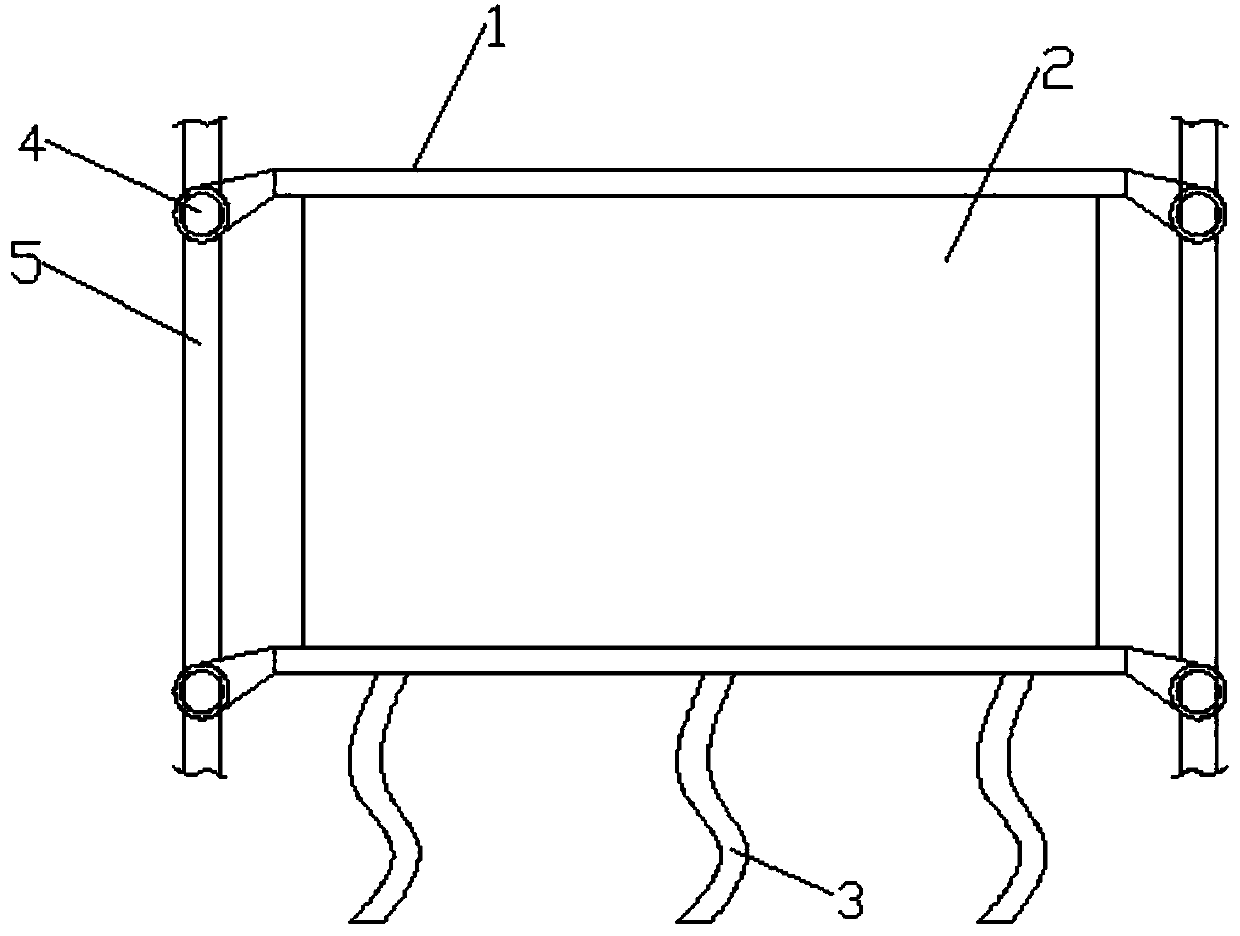

[0022] Such as figure 1 , figure 2 As shown, a shock-absorbing automobile luggage rack includes two fixed rods 1, a luggage basket 2 and an elastic rope 3, and the two ends of the fixed rod 1 are provided with a fastening ring 4, and the fastening ring 4 is sleeved on the longitudinal wall of the car roof. On the rail 5, it is used to fix the fixed rod 1. A luggage basket 2 is arranged between the two fixed rods 1. A shock absorber 6 is arranged in the luggage basket 2. The shock absorber 6 is hollow spherical. The fixed rod 1 is also provided with a Elastic cord 7, is used for fixing luggage.

[0023] The above-mentioned luggage basket is made of the following components in parts by weight: 40 parts of nitrile rubber, 10 parts of modified alkyd resin, 8 parts of ethylene-vinyl acetate copolymer, 4 parts of acrylonitrile butadiene, 3 parts of rosin, 2 parts of cationic starch, 1 part of polymer resin emulsion, 4 parts of diisononyl ester, 6 parts of linear polyethylene, 1 p...

Embodiment 2

[0034] Such as figure 1 , figure 2 As shown, a shock-absorbing car luggage rack includes a fixed bar 1, a luggage basket 2 and an elastic cord 3, and the fixed bar 1 is two cross bars 5 for being fixedly installed on the longitudinal rail 4 of the car roof, and the cross bar 5 Both ends are provided with fastening rings 6, through which the fastening rings 6 are connected with the longitudinal rails 4 of the car roof, a luggage basket 2 is arranged between the two cross bars 5, and a shock absorbing spring is arranged between the luggage basket 2 and the top of the car 7. An elastic cord 3 is also arranged on the fixed rod 1 .

[0035] Further, the luggage basket is made of the following components in parts by weight: 50 parts of nitrile rubber, 20 parts of modified alkyd resin, 12 parts of ethylene-vinyl acetate copolymer, 6 parts of acrylonitrile butadiene, 5 parts of rosin, 4 parts of cationic starch, 2 parts of polymer resin emulsion, 6 parts of diisononyl ester, 8 part...

Embodiment 3

[0046] Such as figure 1 , figure 2As shown, a shock-absorbing car luggage rack includes a fixed bar 1, a luggage basket 2 and an elastic cord 3, and the fixed bar 1 is two cross bars 5 for being fixedly installed on the longitudinal rail 4 of the car roof, and the cross bar 5 Both ends are provided with fastening rings 6, through which the fastening rings 6 are connected with the longitudinal rails 4 of the car roof, a luggage basket 2 is arranged between the two cross bars 5, and a shock absorbing spring is arranged between the luggage basket 2 and the top of the car 7. An elastic cord 3 is also arranged on the fixed rod 1 .

[0047] Further, the luggage basket is made of the following components in parts by weight: 45 parts of nitrile rubber, 15 parts of modified alkyd resin, 10 parts of ethylene-vinyl acetate copolymer, 5 parts of acrylonitrile butadiene, 4 parts of rosin, 3 parts of cationic starch, 1.5 parts of polymer resin emulsion, 5 parts of diisononyl ester, 7 par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com