Tipping bucket self-unloading and lifting device and tricycle with device

A lifting device and self-unloading technology, which is applied to bicycles, passenger bicycles, and vehicles with tilted loads, etc., can solve problems such as potential safety hazards and difficult handling, and achieve the effects of reducing labor costs, improving transfer efficiency, and being easy to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings. It should be understood that the embodiments of the present invention are only used to illustrate the present invention rather than limit the present invention. means, making various substitutions and changes shall be included within the scope of the present invention.

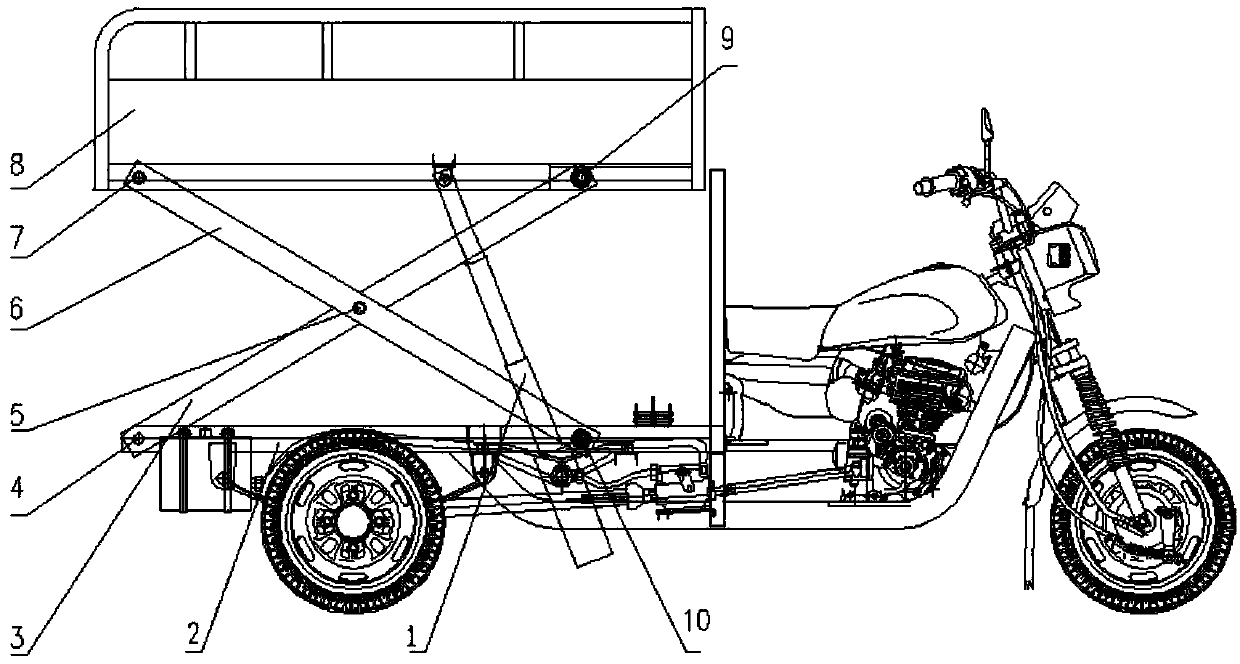

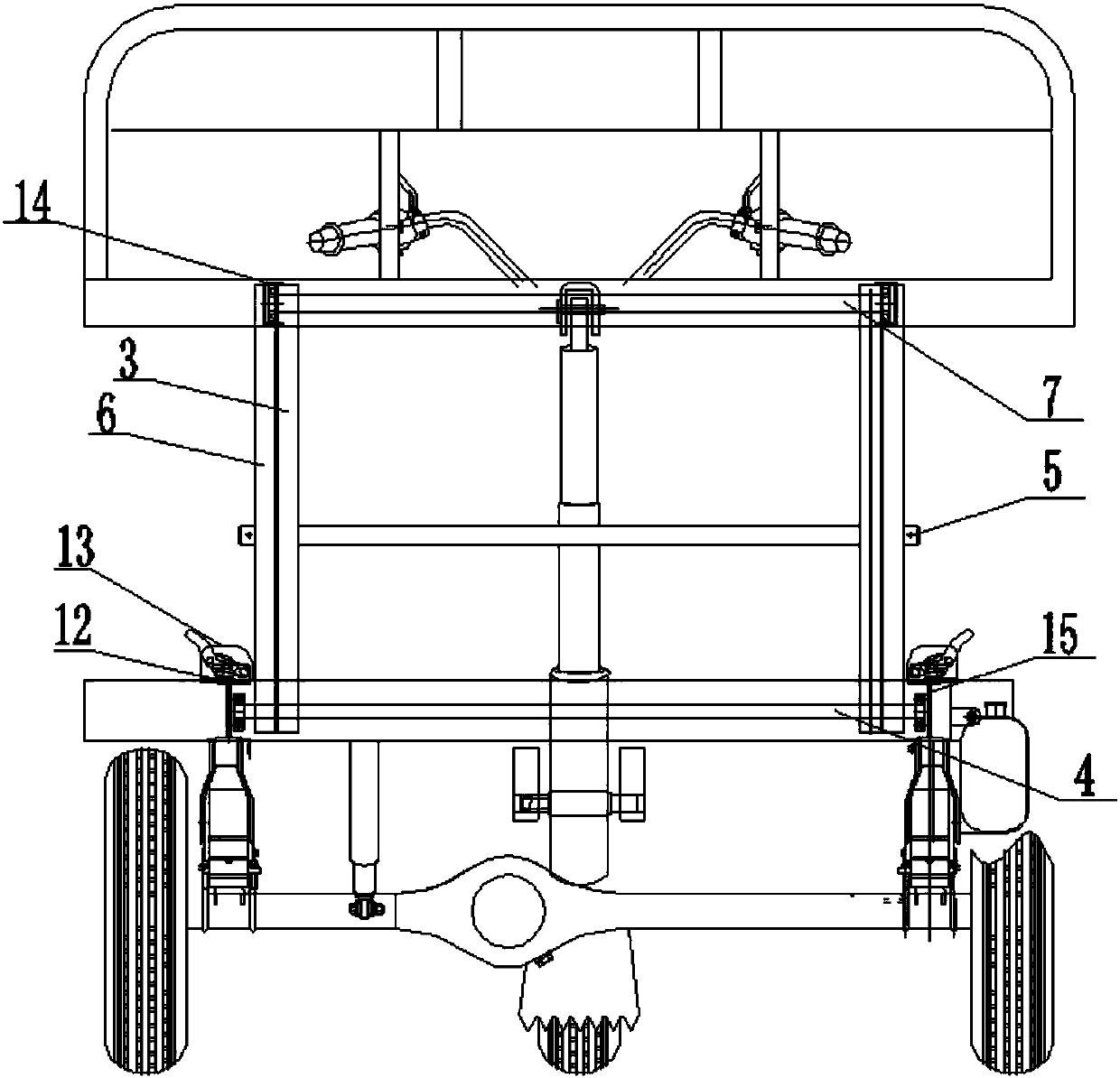

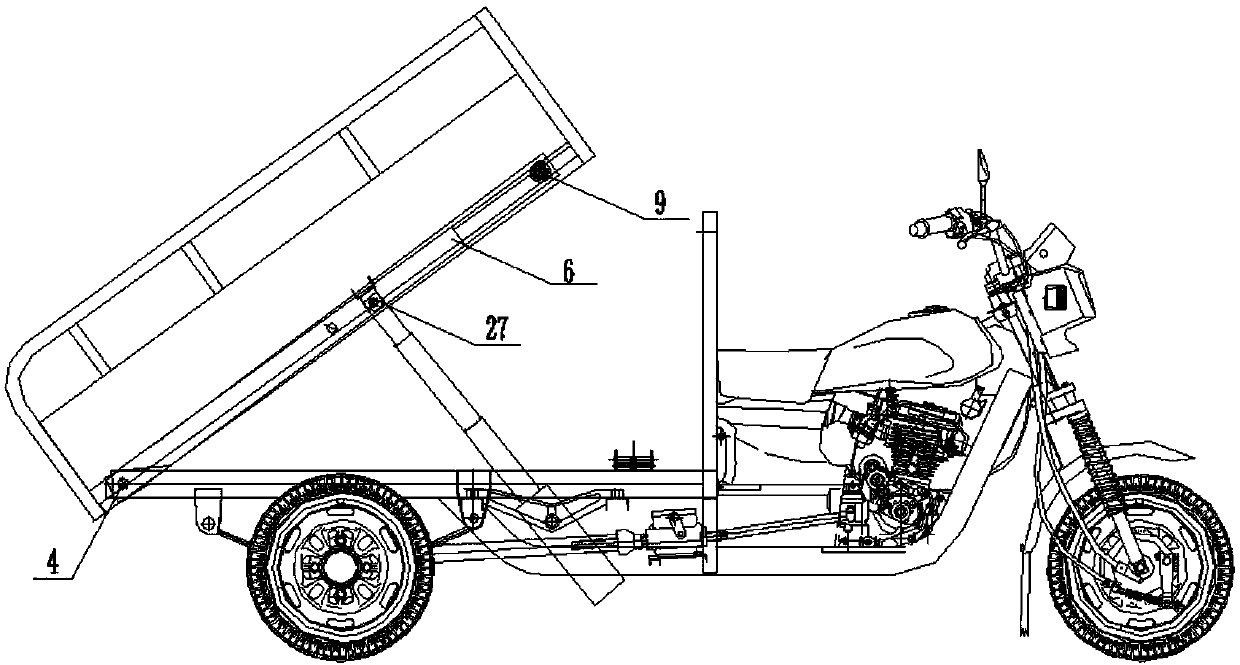

[0027] As shown in the figure, the present invention includes a vehicle frame 2, a jacking oil cylinder 1 fixed on the vehicle frame 2, a hinged lifting frame formed by an intermediate shaft 5 passing through the intersection of a stable inner frame 3 and a stable outer frame 6, a compartment 8, Assembled in the carriage rotating shaft 7 that is connected to the lower end of the rear of the carriage 8 and the rear end of the stable outer frame 6, the channel steel 14 assembled at the lower end of the front of the carriage 8, and the bearing a151 installed at both ends is connected with the front end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com